Adding Value

to Additive Manufacturing

Additive

Manufacturing

Metal Powders and Solutions for AM

Our team of experts ensures success and adds value throughout the additive manufacturing (AM) process. We specialize in manufacturing standard and custom powders, and also produce hardware for powder management. With a focus on quality and innovation, we offer comprehensive solutions tailored to meet the unique needs of our customers.

%20(2).png)

powderrange®

Extensive selection of off-the-shelf alloy powders for metal additive manufacturing.

Our quality metal powders are optimized for additive manufacturing. We are a sustainable partner offering rapid order turnaround and delivery.

Learn More.jpg)

Powder Management

Manage risk, enhance safety and optimize economics with hardware and lab testing services.

Closed-loop powder handling to reduce powder contamination and avoid exposure to safety and environmental hazards.

Learn More.jpg)

Custom Powder

Metal powders designed to deliver the precise mechanical properties your application demands.

For many alloys, Carpenter Additive are able to offer different products of the same composition, optimized for your particular application.

Learn MoreAPPLICATION SPOTLIGHT

Additive Manufacturing

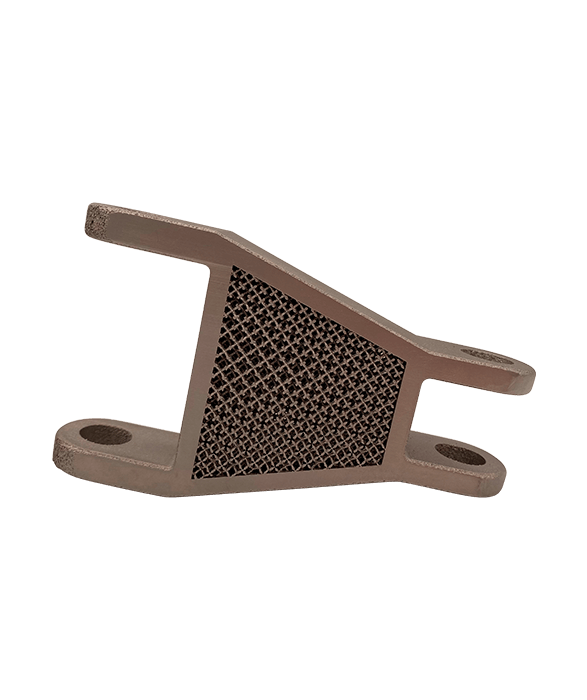

Aerospace Lightweight Brackets

Additively manufactured aerospace brackets are developed to maximize performance while reducing weight through geometry optimization and high-strength materials.

FEATURED PRODUCTS

none

Scalmalloy

Aluminum alloy with exceptionally high fatigue properties, weldability, strength, and ductility with excellent corrosion resistance and a low thermal expansion coefficient

none

Custom 465®

Martensitic, age-hardenable, stainless steel alloy designed to have excellent notch tensile strength and fracture toughness capable of ultimate tensile strength in excess of 250 ksi (1750 MPa)

none

17-4PH

Martensitic precipitation, age-hardenable stainless alloy offering high strength and hardness, and excellent corrosion resistance

none

316L

Stainless steel with corrosion resistance, as well as high tensile and creep strength. Low-carbon version of conventional, austenitic 316

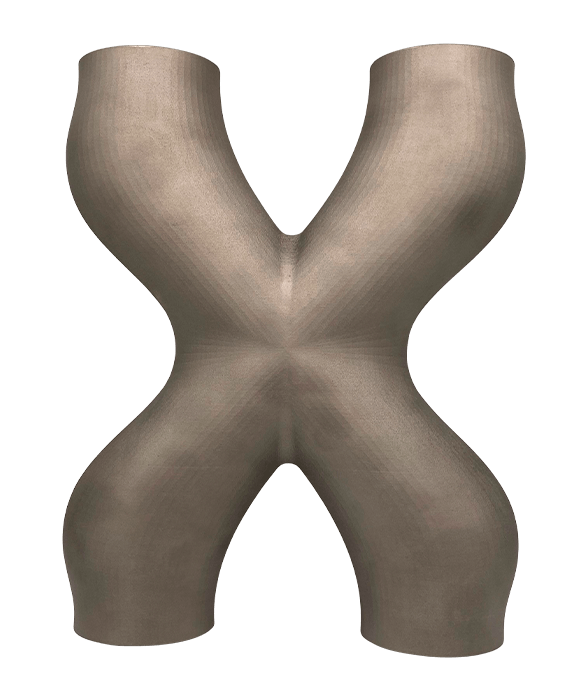

Transportation Exhaust Pipe

Cross over pipe for Transportation exhaust systems and high-performance racing vehicles.

FEATURED PRODUCTS

none

316L

Stainless steel for additive manufacturing, a low carbon, non-magnetic, austenitic stainless steel that exhibits moderate to good strength, good fracture toughness, and good corrosion resistance

none

NiMark® 300 / M300

Low-carbon, maraging nickel steel attaining ultra-high tensile strength that is readily weldable and has excellent notch ductility

none

718

Nickel-base age hardenable alloy with excellent corrosion resistance excellent mechanical property preservation up to 1200°F (650°C)

Energy Turbine Blades

Readily fabricated, crack-free turbine blades additively manufactured in a range of superalloys with elevated temperature stability. These alloys are designed for hot gas path components to take advantage of 3D design freedom which can improve turbine efficiency by leveraging advanced cooling airflow architecture.

FEATURED PRODUCTS

none

718

Nickel-base age hardenable alloy with excellent corrosion resistance and excellent mechanical property preservation up to 1200°F (650°C)

standard

625

Precipitation hardenable nickel-base alloy with molybdenum and niobium with excellent corrosion and oxidation resistance over a range of temperatures

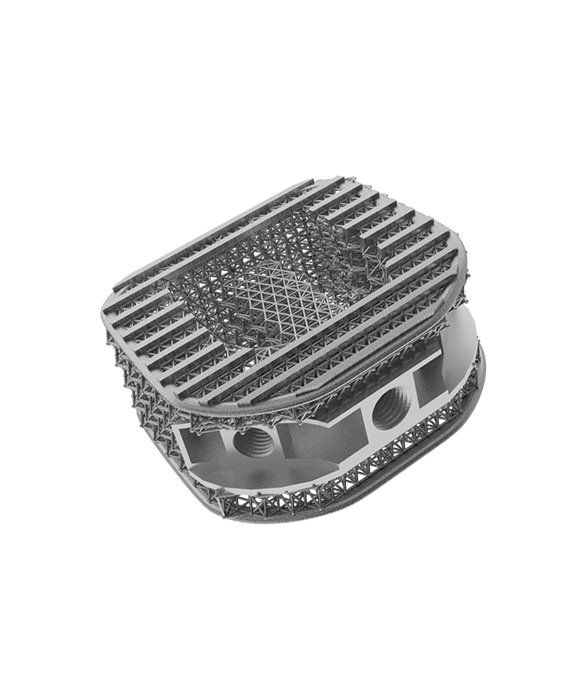

Spinal Cages

Medical implants that take advantage of additive manufacturing for complex component design, efficient control of porous morphology, weight, and adoption of suitable biocompatible alloys. Additively manufactured interbody cages allow for superior osseointegration, improving patient outcomes.

FEATURED PRODUCTS

none

Ti 6Al-4V ELI Grade 23+

Ti64 Grade 23+ combines controlled powder chemistry with lower oxygen content and optimized print parameters to provide 15-20% improvement in mechanical properties

none

Ti 6Al-4V ELI

Extra-low interstitial ASTM B348 Grade 23 has superior damage tolerance and better mechanical properties at cryogenic temperatures

none

Dynamet Ti CP Grade 1-4

Titanium offers increased corrosion resistance and a high strength-to-weight ratio. Available in four commercially pure grades

none

Biodur® 108

An essentially nickel-free austenitic stainless alloy with a high nitrogen content to maintain its austenitic structure with superior tensile and fatigue strength

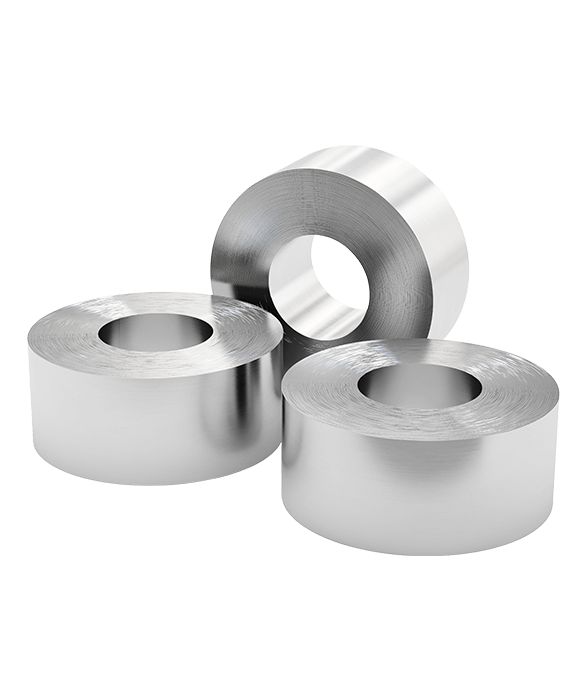

Orthopedic Devices

Orthopedic implants, such as hip and tibial knee components, fabricated by AM take advantage of design flexibility and efficient control of porous morphology, enabling superior osseointegration.

FEATURED PRODUCTS

none

Ti 6Al-4V ELI Grade 23+

Ti64 Grade 23+ combines controlled powder chemistry with lower oxygen content and optimized print parameters to provide 15-20% improvement in mechanical properties

none

Ti 6Al-4V ELI

Extra-low interstitial ASTM B348 Grade 23 has superior damage tolerance and better mechanical properties at cryogenic temperatures

none

Biodur® 108

FDA-approved essentially nickel and cobalt free austenitic stainless with exceptionally high tensile and fatigue strength

Soft Magnetic Components

Advanced soft-magnetic alloys are transforming the profiles and capabilities of torque-dense electromagnetic devices. We print to net shape for high-magnetic induction in small volumes.

FEATURED PRODUCTS

none

Hiperco® 50

High-induction, high permeability soft magnetic alloy to improve magnetic flux density, allowing 10-15% higher force and 10-15% higher power savings

Related Resources

Browse our additive experts' library of resources including white papers, product brochures, technical datasheets, webinars, and more.