aerospace

Avionics

Electrification Drives Efficiency

Our scalable electrification solutions help drive cost savings across the life-cycle of an aircraft. By using soft magnetic alloys for avionics and motors we enable aircraft designers the advantages of motor size reduction and weight savings, making a leaner, more efficient aircraft. Our full-service support allows materials to be stamped prior to heat treating, allowing processing of complex, proprietary forms.

APPLICATION SPOTLIGHT

Avionics

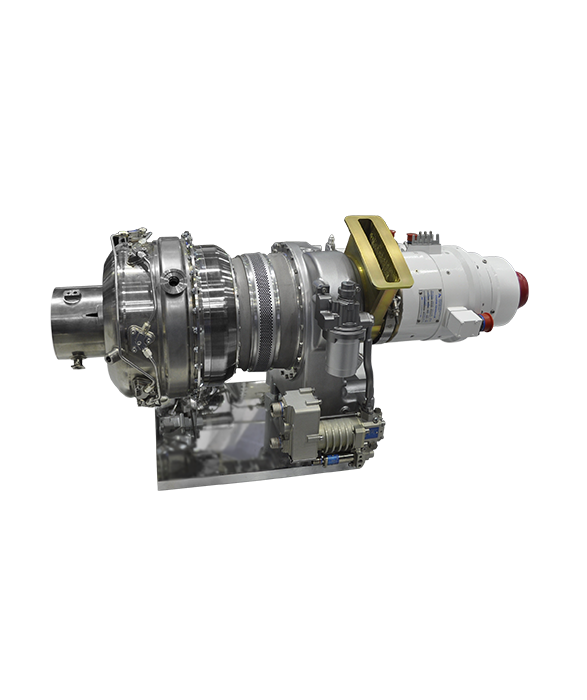

Generator Systems and Auxiliary Power Units (APUs)

High-performance materials enable the design of smaller, lightweight motors and instrumentation without compromising on performance. Our materials enable the most power-dense, smallest, and lightest generators and APUs.

FEATURED PRODUCTS

none

Hiperco® 50

Highest magnetic induction and low losses with mechanical properties that can work to meet both stator and rotor application needs

none

Hiperco® 50A

Highest magnetic saturation with low coercivity and the lowest losses with mechanical properties that help optimize power dense motors and generators

none

Hiperco® 50HS

Highest magnetic saturation with high yield strength, moderate core loss, and mechanical properties that help optimize power-dense motors

none

Hypocore®

Combination of high magnetic induction and low losses for higher continuous power with low cobalt composition and low coercivity

Hybrid Electric Aircraft and UAV

The success of aerospace electrification depends on higher motor and generator power density. Our high-induction soft magnetic alloys help achieve this goal and reduce battery weight thus increasing aircraft range.

FEATURED PRODUCTS

none

Hiperco® 50

Highest magnetic induction and low losses with mechanical properties that can be tailored to meet both stator and rotor application needs

none

Hiperco® 50A

Highest magnetic saturation with low coercivity and the lowest losses with mechanical properties that help optimize power-dense motors and generators

none

Hiperco® 50HS

Highest magnetic saturation with high yield strength, moderate core loss, and mechanical properties that can help optimize power-dense motors

none

Hypocore®

Combination of high magnetic induction and low losses for higher continuous power with low cobalt composition and low coercivity

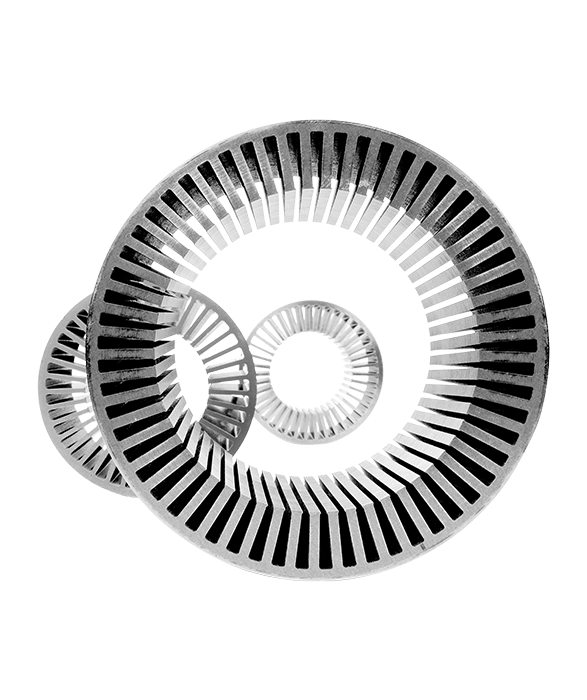

Stator and Rotor Stacks

Our expertise in specialized materials and stack processing ensures the highest performance stator and rotor stacks. We have a deep understanding of metallurgical structure-magnetic property relationships and expertise in various processing technologies. Our methods for dimensional control, high-strength, and tailored magnetic properties support the most demanding design requirements and production tolerances, resulting in superior motor responses.

FEATURED PRODUCTS

none

Hiperco® 50

Highest magnetic induction and low core losses with mechanical properties that can be tailored to meet both stator and rotor application needs

none

Hiperco® 50A

Highest magnetic induction with the lowest core losses for stator applications in power-dense motors and generators

none

Hiperco® 50HS

Highest magnetic saturation with high yield strength, moderate core loss, and mechanical properties that can help optimize power-dense motors

Work with Carpenter Technology to improve your product and your process.

Our solutions are stress-tested in the real world. In 2009, US Airways flight 1549 was forced to emergency land on the Hudson River in New York City. Fortunately, the airplane’s auxiliary power unit was made of our high-performance Hiperco® 50, which enabled the pilot to maneuver the plane and all its passengers to safety.

Related Resources

Browse our growing library of resources for the market including case studies, product brochures, technical data sheets, product selection guides, and more.