aerospace

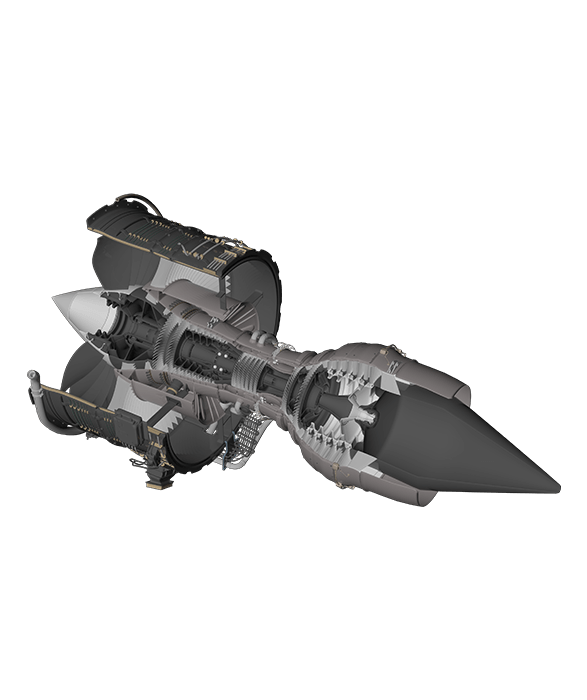

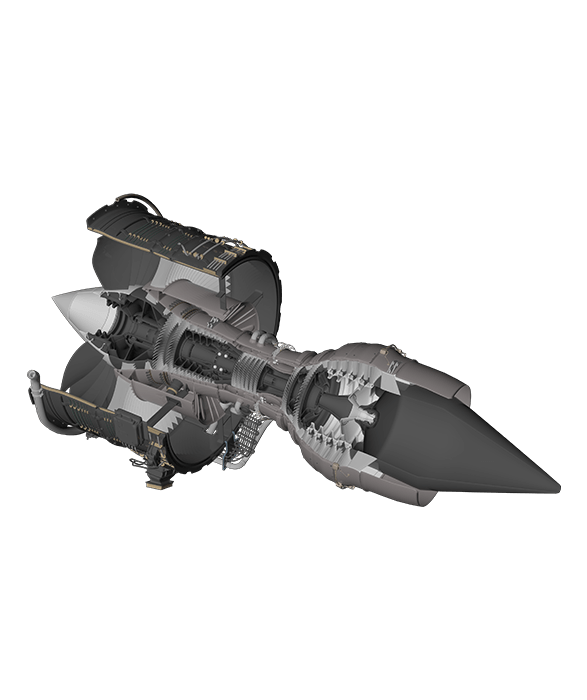

Engines

New Materials - Higher Performance

Advances in engine technology increasingly depend on new material solutions. New materials can deliver stronger performance at higher temperatures, reduce weight, and decrease fuel consumption. From supply reliability to providing trusted advice, we are sought after by the technical community to solve problems and deliver more efficiency, reliability, and cost-effectiveness through superior material performance.

APPLICATION SPOTLIGHT

ENGINES

Casings, Rings, and Vanes

These non-rotating critical components must operate in extremely high temperatures while maintaining their strength.

FEATURED PRODUCTS

none

718

Precipitation-hardened, nickel-base alloy that offers exceptionally high yield, tensile and creep-rupture properties up to 1300°F (704°C)

none

Waspaloy

Precipitation-hardening, nickel-base alloy with good strength and corrosion resistance with high creep resistance and grades for elevated temperature tensile strength

none

Thermo-Span®

Low coefficient of thermal expansion over a broad temperature range

Turbines, Compressors discs, and blades

We help develop fatigue-resistant materials for critical applications that maintain stability at high operating temperatures while withstanding high rotational speeds, high-velocity exhaust, and lateral forces without failure.

FEATURED PRODUCTS

none

718

Precipitation-hardened, nickel-base alloy that offers exceptionally high yield, tensile and creep-rupture properties up to 1300°F (704°C)

none

Waspaloy

Precipitation-hardening, nickel-base alloy with good strength and corrosion resistance with high creep resistance and grades for elevated temperature tensile strength

Shafts

We help designers meet stringent strength and weight requirements with solutions that provide up to 80% more toughness, significantly minimizing the risk of catastrophic failure of this critical component.

FEATURED PRODUCTS

none

NiMark® 250

Low-carbon, maraging nickel steel attaining ultra-high tensile strength that is readily weldable and has good ductility

none

AerMet® 100

High hardness and strength combined with exceptional ductility, high fracture toughness, and exceptional stress corrosion cracking resistance in extreme temperatures

none

718

Precipitation-hardened, nickel-base alloy that offers exceptionally high yield, tensile and creep-rupture properties up to 1300°F (704°C)

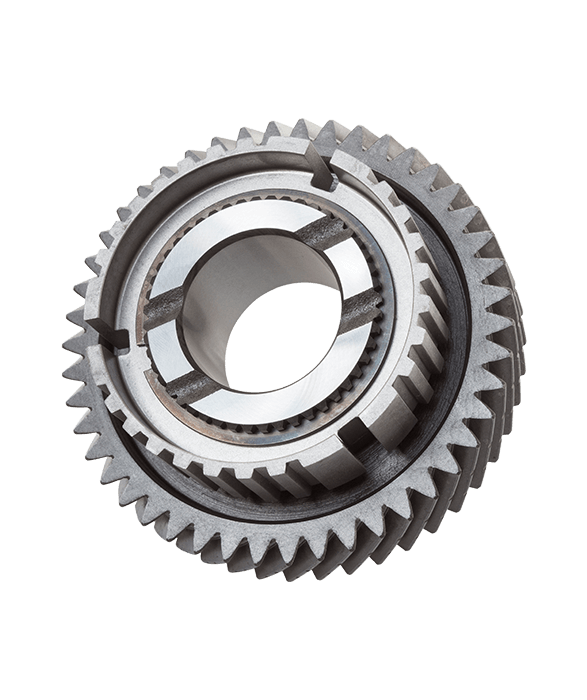

Gears

State-of-the-art gear materials enable advances in engine reliability and efficiency. We help engineers with high performance alloys that can extend part life by withstanding the continually transmitted high torque on these gears.

FEATURED PRODUCTS

none

Pyrowear® 53

Carburizable alloy for good wear resistance, good toughness and good fatigue performance

none

Pyrowear® 61

Premium quality high-strength carburizing steel with ultra-high core strength as well as high fatigue strength, temperature resistance, and hardenability

none

Ferrium® C64

Premium quality carburizing steel with high core strength, high fatigue strength, high temperature resistance and high hardenability

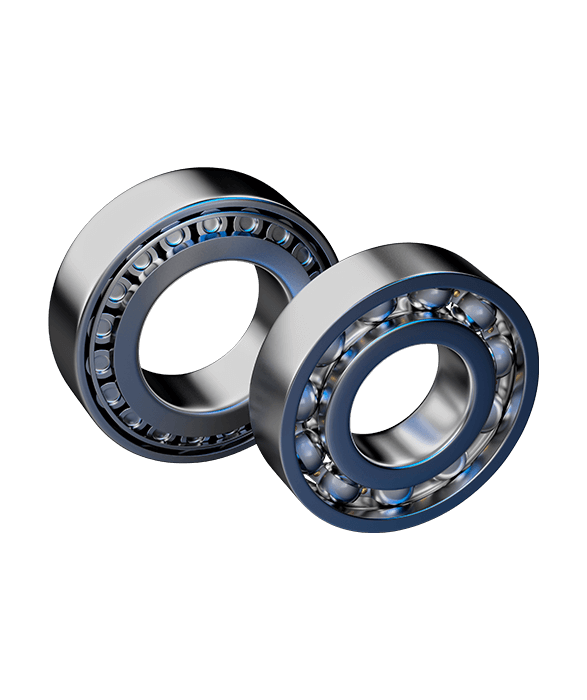

Bearings

Today’s industry goals call for Design for Life engine bearings, continuously pushing material requirements with the evolution of the engine designs increasing loads and speeds while minimizing wear.

FEATURED PRODUCTS

none

M-50

High carbon steel with good wear resistance and fatigue performance

none

CBS-50 NiL

Carburizing grade with high hot hardness characteristics and superior cleanliness

none

52100

High performance, deep-hardening bearing steel where good rolling contact fatigue strength is required at operating temperatures below 400°F (204°C)

Work with Carpenter Technology to improve your product and your process.

Supporting our world-class Reading and Latrobe, Pennsylvania campuses, our leading advanced specialty metals manufacturing facility in Athens, Alabama increases capacity to ensure quality and reduce lead-times. When you're designing the next generation of engines for greater fuel efficiency and increased thrust, turn to our experts for high-quality shafting materials and customized shaft material options that meet your weight, strength, and durability requirements.

Related Resources

Browse our growing library of resources for the aerospace market including case studies, product brochures, technical data sheets, product selection guides and more.