BIODUR® CCM ALLOY Benefits for Orthopedic Medical Implants

White Papers

This PM Processed Cobalt-Based Alloy Offers Many Benefits for Orthopedic Medical Implants

For several decades, orthopedic medical implants have been manufactured mainly from austenitic stainless steels, titanium and titanium alloys, and cobalt-based alloys. The selection of which alloy system to use for a specific application has depended upon a variety of design criteria. These have included biocompatibility, corrosion resistance, tensile strength, fatigue strength, modulus, wear resistance, processing, and cost.

The vast majority of cobalt-based orthopedic implants worldwide have been manufactured using castings of ASTM F75 alloy. Castings in many instances have provided desirable processing flexibility and lower initial costs. However, distinct limitations have been associated with castings, such as coarse grain size, non-uniform microstructural segregation, and lower tensile and fatigue strength. These drawbacks can be overcome by manufacturing cobalt-based implants from “cobalt-chromium-molybdenum” wrought barstock.

Of the three wrought Co-28Cr-6Mo alloys covered under ASTM F1537 and used for orthopedic medical implants, the lowest-carbon (0.14% max) Alloy 1 (UNS R31537), has been utilized most frequently. This alloy has been traditionally manufactured by conventional cast/wrought processing, but can also be manufactured using powder metallurgy (P/M) processing.

Studies to characterize the differences in bar stock made by each of the two manufacturing methods have shown distinct advantages for the P/M process. These benefits include higher strength, improved fatigue resistance, and enhanced microstructural characteristics at both room and elevated temperatures.

Data collected has confirmed that both methods of manufacturing wrought feedstock are superior to casting.

Carpenter Technology conducted the study by manufacturing its version of Alloy 1, known as Biodur® CCM Alloy, by conventional cast/wrought processing. The mill also made the same alloy by Carpenter Technology’s powder metallurgy (P/M) process for comparison purposes.

P/M Benefits

When compared with the conventionally produced cast/wrought alloy, bar stock made by the P/M process was found capable of higher tensile and fatigue strength, increased hardness, finer grain size, and more uniform structure that is less prone to segregation. These attributes were all found in bars in the typical as-supplied warm worked, unannealed conditions.

The powder processed alloy also provided these same relative benefits after exposure to the elevated temperatures typically associated with annealing or forging of orthopedic implants.

The unique advantages imparted by the P/M process, when carried over to machined and forged components, may be expected to improve the performance and life of joint replacement implants and fracture fixation devices such as total shoulder, hip, knee, and shoulder replacements.

The characteristics typically produced by the P/M process allow the F1537 Alloy 1 to be produced in the warm worked or hot worked unannealed conditions in smaller diameter bar and wire products than the conventional cast/wrought alloy. Also, powder processed stock can be made without the need for cold drawing and annealing, which can be detrimental to fatigue strength.

With fatigue strength superior to that of the cast/wrought alloy bar stock, P/M bar stock could be considered for smaller diameter applications requiring higher fatigue capability such as pins, rods, and wire that are typical to some spinal applications.

The powder process should also allow for the production of fully wrought near-net shapes for applications where higher tensile and fatigue strength are required than that possible with castings.

Processes Compared

The conventional cast/wrought alloy is manufactured typically by vacuum induction melting (VIM), electro-slag remelting (ESR) ingots, hot forging to billets, hot rolling into wrought bar stock, then turning and grinding to finish condition.

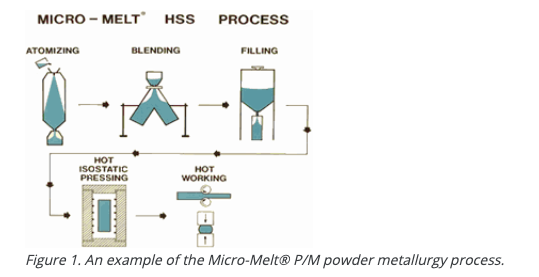

Carpenter Technology’s powder metallurgy process is as follows: vacuum induction melt a heat of high purity gas atomized powder, screen the powder to a predetermined mesh size, blend several heats to make one master blend, fill stainless canisters and hot isostatic press (HIP) to full denseness, hot roll into fully wrought bar stock, turn and grind to finish (Figure 1).

Properties Compared

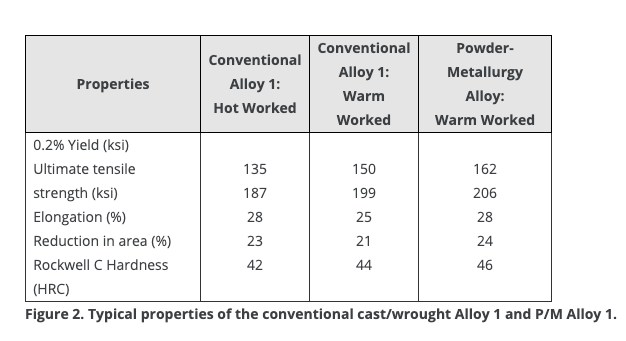

The conventional cast/wrought alloy is offered in the annealed, or more typically in the hot worked or warm worked conditions. The powder processed alloy is typically offered in either the annealed or, more commonly, the warm worked condition. When manufactured to the same metallurgical condition (such as warm worked), the P/M alloy typically exhibits higher yield and ultimate tensile strength. Typical mechanical properties for the alloy manufactured in each manner are shown in Figure 2.

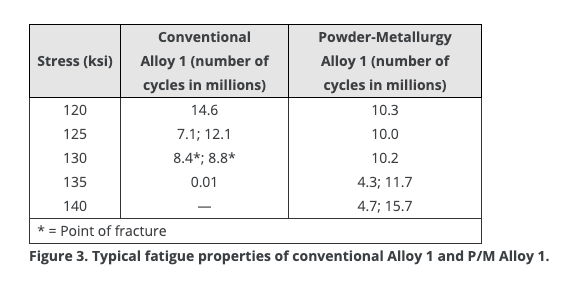

The fatigue results from this study are significantly higher than those found in previous tests to evaluate fatigue properties of annealed plus cold drawn Alloy 1 bar stock. The unannealed bar stock (both cast/wrought and P/M) had significantly higher fatigue properties when compared with annealed and cold drawn Alloy 1 bar stock.

Both the higher tensile and fatigue strength capability of the P/M alloy are attributed to the finer grain size and more uniform microstructure produced by the Micro-Melt powder metallurgy process.

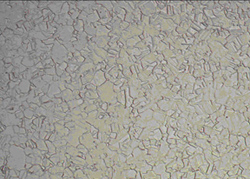

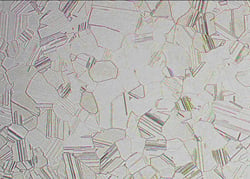

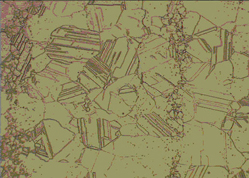

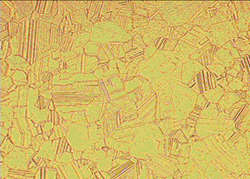

In the warm worked condition, the P/M alloy has a slightly finer grain size than the conventionally produced alloy. The standard cast/wrought alloy has an ASTM grain size of 12.5 with an average grain dimension of 7µ and an average grain area of 50µ2, as shown in Figure 4. The P/M alloy has an ASTM grain size of 13.6 with an average grain dimension of 4.6µ and an average grain area of 22µ2, as indicated in Figure 5.

Figure 4. Typical microstructure of conventional Alloy 1; warm worked bar stock;

longitudinal section; 1000x; etchant HCL + H2O2 (3%).

Figure 5. Typical microstructure of P/M Alloy 1; warm worked bar stock;

longitudinal section; 1000x; etchant HCL + H2O2 (3%).

In further comparison, the conventionally produced hot worked alloy has an ASTM grain size of 11.5 with an average grain dimension of 8.7µ.

Effect of Thermal Treatment

A study was conducted to evaluate the effects of various thermal treatments on the microstructure and hardness of the conventional alloy and the P/M alloy. Samples of the conventional alloy were tested in the unannealed hot worked and unannealed warm worked condition. Samples of the unannealed warm worked P/M alloy also were tested. The samples received 30 minute air-cool heat treatments using a temperature range from 1500ºF (815ºC) to 2100ºF (1149ºC).

Grain structure and hardness were evaluated on the as-received samples and after each heat treat cycle. Microstructure showed that the P/M alloy exhibited a finer ASTM grain size in the as-received unannealed condition, and also maintained that finer grain structure after each heat treatment evaluated (Figure 6).

Figure 6. Effect of thermal treatment on ASTM grain size for the P/M

alloy (MMCCM) and conventional Alloy 1.

Data developed from the evaluation clearly indicates that the powder processed alloy maintains a consistently finer grain size than the cast/wrought alloy throughout the heat treatment range, especially after exposure to temperatures above 1900ºF (1038ºC).

The dramatic differences in grain size capability between the P/M alloy and the cast/wrought alloy can be readily discerned in Figure 7, showing structure for the conventional cast/wrought alloy, and Figure 8, showing structure for the P/M alloy.

Figure 7. Cast/wrought Alloy 1; warm worked + 2100ºF; longitudinal section;

100x; etchant HCL + H2O2 (3%); ASTM grain size 4.5; avg. grain area 11,000 µ2.

Figure 8. P/M Alloy 1; warm worked + 2100ºF; longitudinal section; 100x;

etchant HCL + H2O2 (3%); ASTM grain size 7.0; avg. grain area 2,000 µ2.

Of particular interest is the grain size difference noted in Figs. 7 and 8 after a 2100ºF/30 minute cycle. This is a relatively common forging temperature used during the processing of orthopedic implants. After exposure to a temperature of 2100ºF (1149ºC), cast/wrought Alloy 1 developed a grain size of ASTM 4.5 with an average grain area of approximately 11,000µ2. In contrast, the Micro-Melt P/M alloy developed an ASTM grain size of 7 with an average grain area of approximately 2,000µ2.

More Advantages

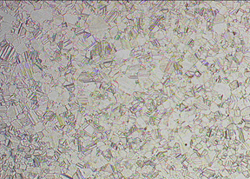

Additional findings further emphasize the unique characteristics of the P/M alloy. At 1900ºF (1038ºC), which is within the carbide precipitate range for the F1537 Alloy 1 tested, a significant difference was observed in the nature of the carbide precipitate between the cast/wrought alloy and the P/M alloy.

As can be seen in Figures 9 and 10, the cast/wrought alloy developed a banded carbide precipitate while the P/M alloy tended to have more uniformly dispersed carbide precipitate. This shows that the P/M process greatly decreases the likelihood for localized segregation and possible banding, which can occur in the cast/wrought alloy at times.

Figure 9. Cast/wrought Alloy 1; warm worked + 1900ºF; longitudinal section;

etchant HCL + H2O2 (3%); carbide precipitate banding.

Figure 10. P/M Alloy 1; warm worked + 1900ºF; longitudinal section;

400x; etchant HCL + H2O2 (3%); uniform carbide precipitate.

The precipitate in both the cast/wrought and P/M material was completely solutioned at 1950ºF (1066ºC). Once solutioned, the carbide does not tend to re-precipitate if exposed again to temperatures in the 1600ºF (871ºC) to 1900ºF (1038ºC) range.

In addition to microstructure evaluations, surface-to-center hardness profiles were also completed on each sample in the as-received unannealed condition, and also after each heat treating cycle. As a result, the P/M alloy was found to have consistently higher hardness on the surface, at mid radius (Figure 11) and at the center in the as-received, unannealed condition as well as after each heat treating cycle, when compared with both the hot worked and warm worked cast/wrought alloy.

Figure 11. Midradius hardness profile of P/M Alloy 1 (HRC MMM) vs. hot worked (HRC MHW)

and warm worked (HRC MWW) cast/wrought Alloy 1.

Conclusion

As previously described, the unique attributes developed by the Micro-Melt® powder metallurgy (P/M) process results in an Alloy 1 F1537 bar material that exhibits higher strength, enhanced fatigue resistance, increased hardness, improved microstructural uniformity, and finer grain size in the unannealed condition as well as after exposure to elevated temperatures. These benefits allow the material to be manufactured to smaller diameters without the need for cold working and annealing, which can be detrimental to grain size and, subsequently, fatigue strength. In addition to a smaller diameter, the alloy also lends itself to the manufacturing of special shapes that could replace castings in certain applications.