Custom 465® Stainless Sees Increased Use

White Papers

Custom 465® stainless is a premium, double vacuum-melted, martensitic age-hardenable alloy that offers an excellent combination of strength, toughness and corrosion resistance. The typical strength of this alloy can be as high as 1758 MPa (255 ksi), combined with fracture toughness of about 88-99 MPa-square-root-meter (80-90 ksi-square-root inch) and corrosion resistance approaching that of Type 304 stainless. Custom 465 stainless is covered by AMS 5936 Rev. C, ASTM A564, and UNS S46500, and is included in MMPDS-05.

Focus on Life Cycle Cost

In today’s competitive business climate, an increasing number of manufacturers are focusing on using raw materials that provide the lowest lifecycle cost rather than the lowest initial cost.

This shift in mindset has created strong worldwide demand for materials that not only possess high strength and toughness properties but are also relatively easy to fabricate, are reliable, and provide long-term service, even in corrosive environments.

Because Carpenter Technology Custom 465 stainless has met these requirements, it has become increasingly popular for not only aerospace applications but other end use markets as well. Despite its higher initial cost than competing stainless and alloy steels such as 15-5PH, 13-8, Type 4340 and 300M, Carpenter Technology Custom 465 stainless has been increasingly specified for applications in the medical, oil and natural gas, consumer, and sporting equipment industries.

Vacuum arc remelt (VAR) furnaces are used to produce premium grade Custom 465 stainless steel.

This patented alloy has been used as a corrosion resistant upgrade to high strength alloy steels. Unlike standard alloy steels, Custom 465 stainless does not require chrome, nickel, or cadmium plating to provide corrosion resistance. Therefore, parts manufactured from Custom 465 stainless would not be susceptible to cracking of or loss of plating that could result in subsequent corrosion attack.

Materials that require coatings for corrosion protection also require periodic inspection to ensure the integrity of the coating. This can add significantly to the life cycle cost of a component, not only because of the cost of the inspection but also due to the down time of the equipment being serviced.

In addition, the environmental issues related to the electroplating process and the disposal of the waste solutions used in that process could pose an even larger problem. The U.S. Environmental Protection Agency has been increasing its regulatory scrutiny of such effluents. Also, the European Union implemented the REACH Regulation in 2007, a phased initiative to ban certain hazardous chemicals including cadmium from select products. Even if cadmium is not entirely banned from all products, future restrictions and regulations could make the cost of disposing of used plating baths prohibitive.

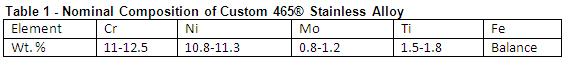

Chemistry, Properties and Microstructure Characteristics

Custom 465 Stainless is manufactured using premium melting methods. The alloy has a strengthening mechanism that is typical of martensitic age hardenable stainless steels, utilizing a final aging treatment to provide the desired properties.

The strengthening and toughening mechanisms of the alloy consist of martensitic phase transformation, followed by a strengthening precipitation of hexagonal Ω-phase needles and orthorhombic Ni3(Ti,Mo) plates. Precipitation introduces strain into the martensitic lattice, which produces the strengthening of the alloy, with maximum strengthening occurring well before precipitates become visible via light optical microscopy. Increasing the aging temperature increases the toughness, but a lower strength is obtained. Furthermore, austenite reversion occurs during aging. The reverted austenite plays a significant role in the ductility of the alloy. All the above microstructural features combine to provide Custom 465 stainless with its superior high strength and toughness.

The final microstructural features of Custom 465 stainless are also influenced by the premium double vacuum melting as well as the subsequent hot working the alloy receives prior to the final thermal treatment.

Figure 1 - Typical Micrograph of Custom 465® Stainless in H950 Condition

Heat Treatment of Custom 465 Stainless

For Condition A – solution annealed, the alloy should be heated to 982°C +/- 8°C (1800°F +/- 15°F) and then held for one hour and cooled rapidly. Solution annealing should be followed by refrigerating to -73°C (-100°F), holding for eight hours and then warming to room temperature. Subzero cooling should be performed within 24 hours of solution annealing.

For conditions H 900, H950, H1000, H1050, H1100 and H1150, Custom 465 stainless steel uses a single age hardening step consisting of heating to a selected temperature between 482 and 621°C (900 and 1150°F), holding for four hours, followed by air cooling or liquid quenching. A liquid quench is preferred for section sizes greater than 3 inches. The aging temperature used will depend upon the desired combination of strength, ductility, toughness and stress corrosion resistance.

Comparison of Properties

The tensile strength of Custom 465 stainless varies from 1034 MPa (150 ksi) to more than 1724 MPa (250 ksi) depending on the aging treatment used. In addition, cold working the alloy prior to aging can result in tensile strength values in excess of 1931 MPa (280 ksi). Aging temperatures ranging from 510°C (950°F) to 566°C (1050°F) are often selected in order to achieve the desired balance of strength, toughness and stress corrosion cracking (SCC) resistance. Typical applications call for Custom 465 stainless in the H950 or H1000 conditions.

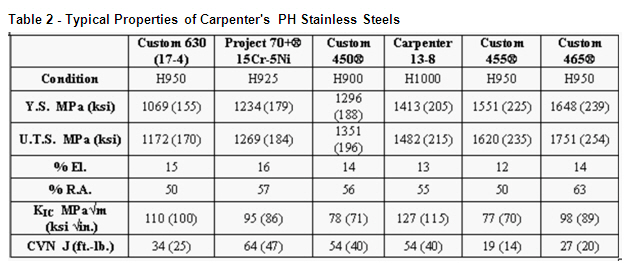

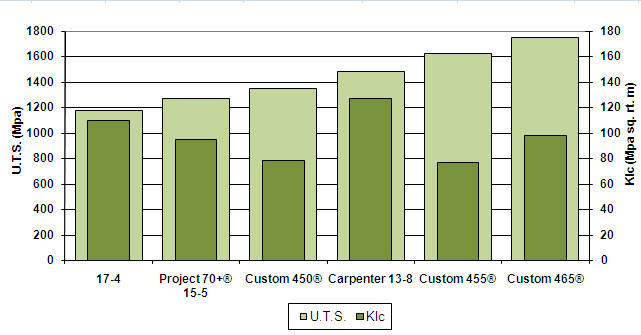

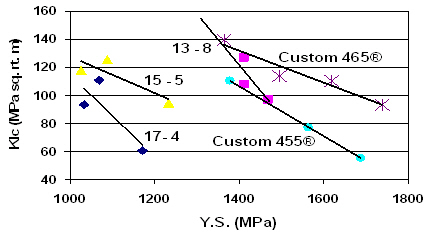

The H950 condition (510°C [950°F]) is most commonly used to obtain higher strength together with good toughness and excellent notch tensile strength. In the H950 condition, Custom 465 stainless is capable of ultimate tensile strength in excess of 1724 MPa (250 ksi). This strength is higher than that of any other historically available PH stainless steel long product. The H1000 condition (538°C (1000°F)) is chosen to obtain increased toughness at a slightly lower strength level. This condition provides a superior combination of strength, toughness, ease of fabrication, and stress corrosion cracking resistance when compared to other high strength PH stainless alloys such as Custom 455® stainless (UNS S45500) and 13Cr-8Ni stainless (UNS S13800).

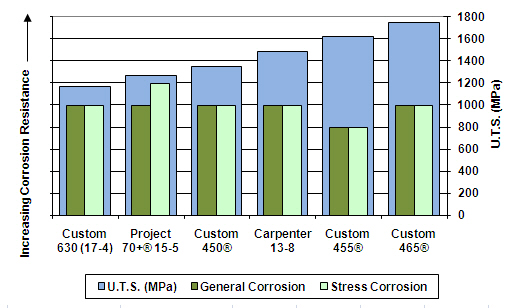

Table 2 and Figure 2 provide a comparison of typical properties of PH stainless steels in their typical heat treated conditions. Figure 3 shows the relationship between yield strength and fracture toughness of commonly used PH stainless steels in multiple heat treated conditions.

Figure 2 - Relative Strength and Toughness of PH Stainless Steels

Figure 3 - Relationship Between Yield Strength and Fracture Toughness of PH Stainless Steels

Corrosion Resistance

The general corrosion resistance of Custom 465 stainless approaches that of 304 stainless. In both the H950 and H1000 conditions, exposure to 5% neutral salt spray at 35°C (95°F) per ASTM B117 resulted in no corrosion after more than 2,000 hours of exposure.

Stress corrosion cracking resistance is also quite good. Data obtained via use of the Rising Step Load test method, with samples in the H950 condition tested in 3.5% NaCl solution, natural pH, at open circuit potential, have shown Custom 465 stainless to maintain an excellent KISCC value in relation to its strength.

Furthermore, stress corrosion resistance improves with increasing aging temperature. Samples tested using the same RSL test parameters but in the H1000 condition show 90% retention of original KIC values under the KISCC conditions. Custom 465 stainless has comparable SCC resistance to 13Cr-8Ni and Custom 455 stainless at the same aging temperatures, but at a significantly higher strength. Also, stress corrosion resistance of Custom 465 stainless is superior to both alloys when over aged to the same strength level.

Figure 4 illustrates the relative strength, general corrosion resistance and stress corrosion cracking resistance of traditional PH stainless steels.

Figure 4 - Relative Strength and Corrosion Resistance of PH Stainless Steels

First Developed for Aerospace Applications

While it has since become obvious that it could be considered for a myriad of other end-use applications, Custom 465 stainless was originally designed to help meet the demands from the aerospace industry for materials that could enable aircraft to keep flying 30 years or more with minimal maintenance.

As part of the aerospace alloy development process, which tends to have a longer timeline than that for non-aerospace materials, Carpenter partnered with several aerospace companies to determine and refine their requirements for a new material. As could be expected, airframe producers were seeking to maximize corrosion resistance, fatigue resistance and mechanical strength in one alloy.

Following about seven years of testing, Custom 465 stainless received AMS 5936 and ASTM A564 aerospace specifications, was included in MMPDS, and was qualified for use by major aircraft manufacturers.

Presently Custom 465 stainless is used by major airframe manufacturers worldwide for such structural applications as torque tubes, pneumatic cylinders, braces, struts, fuse pins, and other leading and trailing edge structural elements. The most recent inroads have been made in gimbals, seat tracks, slat tracks and flap tracks.

In addition to the specific uses mentioned above, Custom 465 stainless could be considered as a corrosion resistant replacement for 300M, AISI 4340 and similar grades of steels that must be plated or otherwise surface coated to provide corrosion resistance. It can also be considered as a higher strength replacement for 15-5, 17-4 and 13-8 stainless steels, which, while having acceptable corrosion resistance, have lower than desired strength and toughness.

Other End Uses

Custom 465 has enabled the aerospace industry to design improved components, either by allowing a switch to a stainless from a non-stainless steel without mechanical property degradation, or by improving the strength of an existing stainless steel part. This alloy has been used for a growing number of other applications including those in the medical, energy, automotive, sporting equipment and hand tool industries, as well as other industrial and consumer related sectors. More recent uses of this versatile alloy have been in the medical, oil and natural gas and sporting equipment markets.

Medical

The evolution of new surgical techniques requires the development of higher performance medical instruments that will not break, distort or otherwise fail during surgery. Materials used in the fabrication of today’s minimally invasive instruments must withstand higher operational torque loads and multiple autoclaving cycles. Custom 465 stainless is included in ASTM F899, the governing specification for stainless steels for surgical instrument applications.

The combined high strength and toughness of Custom 465 stainless has enabled the design of longer and smaller cross-section components such as endoscopic instruments that have been used for minimally invasive surgeries. These smaller cross-section instruments allow smaller incisions, which speed the recovery rates of patients and shorten hospital stays.

For parts with diameters less than 20 mm (0.75 in.), cold-worked and aged Custom 465 stainless has achieved a tensile strength approaching 300 ksi (2070 MPa) and has been used for surgical and dental instruments and needle wire.

Custom 465 stainless has been used for scrapers, cutters, and suture needles and, where warranted, medical devices have included a coating such as titanium nitride or aluminum nitride to provide a sharper cutting edge.

Energy

Premature equipment failures in deep-hole drilling operations can result in the loss of expensive tools and valuable production time. Drive shafts used for downhole drilling tools are typically made from EN30B or 4330V. Newly designed drive shafts and mud motors manufactured from Custom 465 stainless can last up to 1,500 hours before replacement is required. This tenfold increase in service has dramatically reduced total replacement costs, as well as the costs associated with lost drill rig production time.

Custom 465 stainless in the H1000-H1050 condition has provided nearly twice the ultimate tensile strength of the alloy steels replaced, along with excellent notch tensile strength and fracture toughness. It also offered superior resistance to general corrosion and stress corrosion cracking. It also can be considered for pumps, valves and other related parts.

Automotive

Custom 465 stainless has been used for such components as suspension coil springs, engine valve springs, torsion bars and instrumented wheel sensors to prevent corrosion related failures, improve vehicle performance, save weight and make the components stronger. It could also be considered to replace 17-4 and other PH stainless steels in certain high end automotive, especially high-performance and racing applications.

Hand Tools

style="margin: 0px 0px 10px;">High-performance hand tools made from Custom 465 stainless offer a unique combination of attributes that have been considered useful to the medical, biomedical, biotech, pharmaceutical, food, nuclear, marine and other industries concerned with clean room sterility and/or exposure to corrosive environments.

A typical example is the use of Custom 465 stainless for conventional screwdrivers, L- and T-pattern hex keys, and ball-end L-pattern hex keys. In this application, the alloy reportedly combines high strength, high hardness, high toughness, and the torque capability of the most suitable carbon steels with superior resistance to both general corrosion and stress corrosion cracking. The tools are autoclaveable and resistant to surface oxidation in a steam environment.

Sporting Goods and Equipment

Custom 465 stainless has been used for a wide array of sporting goods and equipment including golf club faceplates. The higher strength properties of Custom 465 stainless over certain lower strength PH stainless steels, for example, allow the designer to make the faceplates thinner and redistribute the saved weight for optimum balance.

The alloy has also been used for the wire face shields on such protective equipment as lacrosse helmets and for big-bore firearms cylinders such as the Ruger Super Redhawk .454 Casull revolver.

Conclusion

When comparing the corrosion and mechanical properties of Custom 465 stainless with that of other stainless steels or with alloy steels, it has been shown that Custom 465 stainless possesses the exceptional attributes that makes it capable of meeting the critical application requirements of various industries, such as the aerospace, medical, automotive, consumer and industrial sectors. The alloy has already found diverse new applications in many industrial sectors and, given its attributes, could potentially develop new end uses in the future.

Custom 455 and Custom 465 are registered with the U.S. Patent & Tm. Office to CRS Holdings, Inc., a subsidiary of Corp.

***

By Arvind Midha, Regional Metallurgist, Western USA

and David E. Wert, Metallurgist, Stainless Research and Development

Corp., Wyomissing, PA, USA

Published in Advanced Materials & Processes, Sept. 2011