Selecting Controlled Expansion Alloys

Technical Guide

Alloys with controlled expansion characteristics are used for a broad variety of applications where thermal size change of the metal must be considered in component part design. Generally, these alloys expand when heated and contract when cooled.

Composition and crystal structure, together, help determine the thermal expansion behavior of each alloy. The alloy expansion rate is commonly expressed in terms of an average or mean coefficient of thermal expansion.

The expansion behavior of some alloys is not linear. Therefore, it is important to specify the upper and lower temperature limits of interest when describing the expansion coefficient needed in any material.

There are three general types of controlled expansion alloys:

- Low thermal expansion - these are predominantly iron-nickel alloys having very low expansion coefficients within certain temperature ranges. They are used generally in electronic devices, instrumentation and thermostats.

- Matching expansion - these alloys possess approximately the same expansion coefficients as the glasses and ceramics commonly used in the electronics industry.

- High thermal expansion - these are alloys which exhibit high expansion coefficients…higher, for example, than those for stainless steels and carbon steels. They are used primarily in thermostat applications.

Low Expansion Alloys

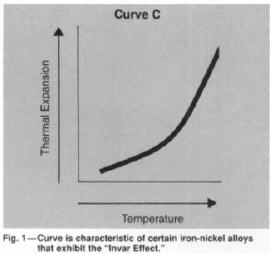

The low expansion alloys have very low coefficients of thermal expansion - less than 1.8 to approximately 9 x 10-6 per °C (1.0 to approximately 5.0 x 10-6 per °F) - within certain temperature ranges. These alloys exhibit unusual expansion behavior; it is represented by the curve in Fig. 1.

The unique expansion characteristic of this alloy family is related to ferromagnetism. Each alloy exhibits very low thermal expansivity below its Curie temperature: i.e., the temperature below which it is ferromagnetic. This low thermal expansivity anomaly, often referred to as the "Invar Effect", is related to spontaneous volume magnetostriction where lattice distortion counteracts the normal lattice thermal expansivity.

Above the Curie temperature, the alloys expand at a high rate because they are no longer ferromagnetic. A number of theories have been proposed to explain this "Invar Effect"

.

Although these theories have given insight to the phenomenon, the mechanism is not yet sufficiently understood. In addition, with certain nickel-iron compositions, it is possible to obtain a very high magnetic permeability. Consequently, the alloys in this family have been useful in applications requiring high magnetic permeability such as transformers, cores, laminations for very efficient motors, relays and solenoids.

All of the alloys in this group are iron-nickel or iron-nickel-cobalt alloys with face-centered cubic crystal structure. As nickel content in the iron-nickel alloys increases from 36 percent, thermal expansivity and Curie temperature also increase. Curie temperature increases from 280°C (536°F) for 36 percent nickel to greater than 510°C (960°F) for 50 percent nickel. Thus, consideration in selecting an alloy also must be given the useful temperature range as might be limited by the Curie temperature.

Two Categories

Uses of low-expansion alloys are divided into two general categories. First are those in which size change due to temperature variation must be minimized. These applications include structural components for measurement and control instruments in which excessive expansion and contraction due to temperature changes would seriously impair accuracy. Typical applications include aircraft and missile control components, laser and optical systems and wave guide tubes.

The second category includes temperature controls utilizing a bimetallic strip. This simple type of control consists of a low expansion alloy metallurgically bonded to a high expansion alloy to produce a bimetallic element. When the strip is heated, the difference in thermal expansion rates between the two alloys causes the element to bend in curvature.

The change in curvature is directly proportional to the difference in coefficient of expansion and the temperature change of the strip components, and inversely proportional to the thickness of the combined components. The amount of bending is also affected by the ratio of the moduli of elasticity of the two components and by their thickness ratio.

One of the best known low expansion alloys is Carpenter Technology Invar "36"® alloy (UNS K93601), a 36 percent nickel-balance iron alloy. It has been used in applications such as radio and electronic devices where dimensional changes due to temperature must be minimal, for structural members in precision optical laser measuring devices and as the low expansion side in bimetal thermostats.

Two alloys in this family are suitable for unique low expansion requirements. Carpenter Technology Free-Cut Invar "36"® alloy (UNS K93602), with a slight increase in expansion properties, offers improved machinability for applications where high parts productivity is important. This alloy has been used for aircraft controls and a variety of electronic devices.

The second alloy - Carpenter Technology Super Invar "32-5" alloy - is an iron-nickel-cobalt alloy which exhibits approximately one half the thermal expansivity of Carpenter Invar "36" alloy at or near room temperature. It has been used for structural components and supports for optical and laser instruments.

The ASTM F1.03 Subcommittee on Metallic Materials has formed a Task Group to develop an ASTM standard specification for 36 percent nickel Invar and free machining Invar, as well as for Super Invar. It is hopeful that this new specification will be available some time in 1995.

Any one of four other low expansion alloys may be particularly suitable for service at higher temperature ranges. For example, Low Expansion "39" alloy (ASTM B-753) has a useful low thermal expansivity extending to approximately 340ºC (644ºF). It has been used for tunable capacitors and as the low expansion element in thermostat bimetal products.

Carpenter Technology Low Expansion "42" alloy (ASTM B-753) has a virtually constant low rate of thermal expansion at temperatures up to about 380°C (716ºF), while Low Expansion "45" alloy (ASTM B-753) has a relatively constant rate of thermal expansion to about 440°C (824°F). Both metals have been used in thermostats and thermoswitches. The thermal expansivity of the higher-nickel alloy approximates the thermal expansivity of some alumina ceramics over certain temperature ranges.

The alloy in this family with the highest nickel content, Low Expansion "49" alloy, has been used for glass sealing of fiber optics.

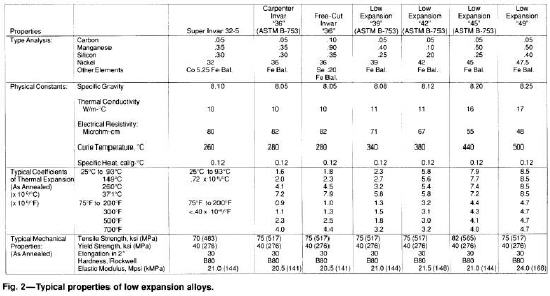

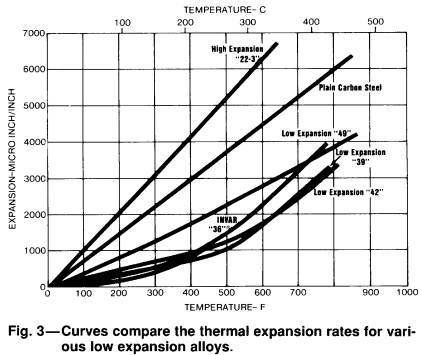

For type analysis and typical properties of these low expansion alloys, see Fig. 2. Expansion curves are plotted in Fig. 3.

Fabrication

The low expansion alloys machine similar to, but not as good as a Type 316 austenitic stainless steel. They are readily machinable, although they do produce gummy chips. Therefore, large, sharp and rigidly supported tooling is recommended, with slower speeds.

All of the alloys are very ductile, thus can be readily cold headed and formed. Stamping from cold rolled strip is easily accomplished. Parts may be deep drawn from properly annealed strip.

Fabrication does add stresses which, unrelieved, can change the thermal expansion behavior. For that reason, parts placed in service as fabricated may not meet design requirements.

After severe forming, bending and machining, relief of stresses introduced by these operations can be accomplished by annealing at temperatures of approximately 1400 to 1800°F for a time sufficient to thoroughly heat through the section. However, the nickel-irons will oxidize readily at these high temperatures.

When annealing cannot be done in a non-oxidizing environment (vacuum, dry hydrogen, dissociated ammonia, etc) sufficient material must be allowed on work pieces to clean up by light grinding, pickling, etc., after annealing. Stress relief for sections having light finishing cuts or grinding performed after annealing is accomplished by heating to 600 to 800°F, for a time to uniformly heat through the work piece.

Matching Expansion Alloys

One family of alloys possesses thermal expansion characteristics that are compatible with those of certain glass and ceramic materials. These specialty alloys are designed specifically to match the rate at which glasses and ceramics cool from various elevated temperature ranges.

This characteristic allows lasting metal-to-glass fusion in hermetically-sealed devices. The glass/metal interface is heated until the glass becomes molten and wets to the oxide layer on the alloy surface.

As it cools, the glass sets. As cooling continues, it is very important that the glass and metal contraction behavior is similar below the glass strain point. When there are excessive contraction differences between the materials being sealed, the stresses will cause glass breakage.

Hermetic seals have been used for many years, with great success, to protect vacuum tubes from the environment, then transistors and more recently, semiconductors. With the evolution of the integrated circuit, these alloys have played a critical part in sealing the chip within the ceramic substrate.

Alloys used for glass-to-metal seals tend to form a surface oxide which is readily "wetted", or chemically bonded to certain glasses. This property, in all the iron-chromium and iron-nickel sealing alloys, assures high quality seals of good strength and hermeticity. It is general practice to pre-oxidize the metal parts in a special, controlled-atmosphere furnace before the actual glass sealing.

The use of ceramic-to-metal seals for all types of electronic devices has increased substantially. These seals often have consisted of a metallized alumina (Al2O3) or beryllia (BeO) substrate brazed to a controlled expansion alloy member.

Ceramic parts are often produced with a metallized surface in order to attach the expansion alloy. In the case of alumina, the "moly-manganese" process is the most widely used to metallize the surface. After plating with nickel or nickel and gold, controlled expansion alloy parts are then soldered or brazed to the metallized ceramic, often in a continuous or batch-type furnace with a controlled reducing atmosphere. Well brazed joints can be obtained consistently by proper adjustment of temperature, time, atmosphere and fixturing.

Sealing Alloy Choices

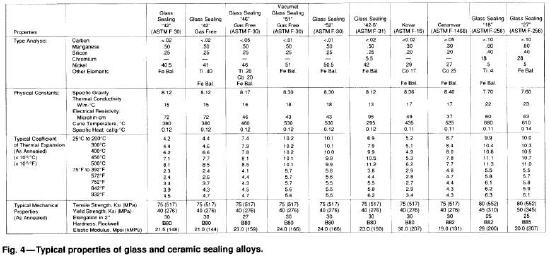

The materials specifier can select any one of 10 glass and ceramic sealing alloys to match the thermal expansion characteristics of the part or assembly to be protected. (Fig. 4).

Carpenter Technology Kovar® alloy (ASTM F-15 - also known as Rodar® alloy) is a low expansion alloy that has been used extensively for both glass-to-metal and ceramic-to-metal sealing. It provides a strong hermetic seal to the hard borosolicate glasses and ceramic materials such as those used in power tubes, microwave tubes, transistors and diodes, as well as high-end electronic products such as miniaturized integrated circuits.

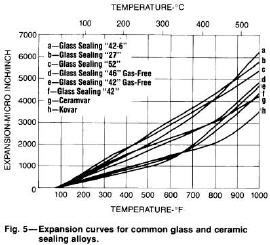

This is one of only two alloys in the glass and ceramic sealing family containing a large amount of cobalt (17 percent). Cobalt lowers the thermal expansivity of low expansion iron-nickel alloys, as shown by the curves in Fig. 5.

Ceramvar® alloy (ASTM F-1466) is the other cobalt-containing (25 percent) alloy that is generally considered for applications where Kovar alloy may not provide the service needed. This iron-nickel-cobalt alloy is specially designed for ceramic-to-metal sealing. It has expansion characteristics more closely matching those of alumina ceramics for high temperature brazing applications.

Six iron-nickel alloys offer a range of thermal expansion characteristics suitable for glass sealing applications. As nickel content changes, so do essential properties such as thermal expansivity and Curie temperature.

Carpenter Technology Glass Sealing "42" alloy (ASTM F-30; Alloy No. 42) has been used most commonly for integrated circuit lead frames, and other selected glass-to-metal sealing applications.

A modification of this material, known as Glass Sealing "42" Gas-Free alloy, is designed for bubble-free glass-to-metal seals. The composition of this alloy is carefully controlled to prevent formation of carbon dioxide or carbon monoxide bubbles at the seal interface. This characteristic makes the alloy useful for terminals for enameled resistors, industrial lamps and automotive headlamp ferrules which accept electrical contact.

A special thermal treatment for Carpenter Technology Glass Sealing "42-6" alloy (ASTM F-31) develops a tightly adherent oxide beneficial to obtaining a durable hermetic seal. Metal parts are usually pre-oxidized by thermal treating prior to the glass sealing. This alloy has been used for sealing to Corning 0120 glass.

Glass Sealing "46" Gas-Free alloy (ASTM F-30; Alloy No. 46) has been used for terminal bands in enameled resistors and for enameling without degasification. Glass Sealing "51" Gas-Free alloy (ASTM F-30; Alloy No. 51), with still more nickel content, is used generally in dry reed switches and hermetic feed-throughs.

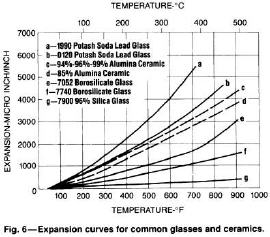

The last of the six iron-nickel alloys, Carpenter Technology Glass Sealing "52" alloy (ASTM F-30; Alloy No. 52), is used almost exclusively for pin feed-throughs for semiconductor devices. This alloy has been found successful for sealing to soft glasses like potash soda lime glass. Soft glasses have higher expansion coefficients - in the range of 7 to 11 x 10-6 per °C (4 to 6 x 10-6 per °F) - than the hard borosilicate glasses with coefficients of approximately 3 to 5 x 10-6 per ºC (1.5 to 3.0 x 10-6 per °F) which are better sealed with Kovar alloy Expansion curves for some of the common glasses are shown in Fig. 6. Two ductile iron-chromium alloys - Carpenter Technology lass Sealing "27" alloy (ASTM F-256; Type II) and Carpenter Technology Glass Sealing "18" alloy (ASTM F-256; Type I) -are used for high volume glass-to-metal sealing applications such as fluorescent tube feed-throughs and as stud pins and other support members inside television monitors.

Glass Sealing "27" alloy has been used extensively for seals in electronic and vacuum tubes, and fluorescent lamps. Carpenter Technology Glass Sealing "18" alloy is used widely in television monitors and in flourescent lamps. The chemistry of this alloy is balanced to prevent phase transformation through the high temperature glass sealing cycle.

Fabrication

The iron-chromium glass sealing alloys do not exhibit the "Invar Effect" as do the iron-nickel low expansion alloys; their expansion rate is nearly linear. The alloys are ductile. They can be stamped, deep drawn into parts on a mass production scale and used in the annealed condition.

Both of the iron-chromium alloys are mechanically harder than the iron-nickel alloys and the iron-nickel-cobalt grades, therefore may be easier to machine. With their good ductility, they may be readily formed and deep drawn for high volume part production.

Manufacture of these controlled expansion alloys can be controlled, within specification limits, to provide the properties best suited to a particular fabrication operation. Factors that contribute to fabrication characteristics include composition, mechanical properties, internal quality of the metal, surface quality, shape and dimensional tolerances. For instance, deep drawing of sheet or strip requires a combination of small grain size, excellent ductility and non-directional mechanical properties.

High Expansion Alloys

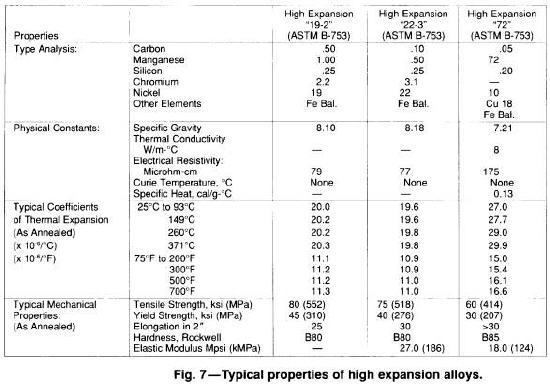

The high expansion alloys are often iron-based alloys, usually containing nickel and chromium. Sometimes, certain common stainless steels are used as well. There is one important high expansion, non-ferrous alloy. Three (Fig. 7) high expansion alloys are used almost exclusively as the high expansion component in thermostat bimetal applications.

Carpenter Technology High Expansion "22-3" alloy (ASTM B-753) - with 22 percent nickel, 3 percent chromium and balance iron - has thermal expansion properties higher - equal to or greater than 19.8 x 10-6 per °C (11 x 10-6 per °F) - than any of the alloys in the Type 300 stainless steel series.

A companion grade, Carpenter Technology High Expansion "19-2" alloy (ASTM B-753) - containing 19 percent nickel, 2 percent chromium and balance iron -has a thermal coefficient of expansion similar to that for Carpenter Technology High Expansion "22-3" alloy. The 19-2 alloy, however, can be manufactured to higher tensile strengths for bimetal thermostats that must be stronger and/or springier.

Carpenter's Carpenter Technology High Expansion "72" alloy (ASTM B-753) is a unique non-ferrous alloy which has a significantly higher thermal expansivity than the ferrous high expansion alloys. This alloy contains a nominal 72 percent manganese, 18 percent copper and 10 percent nickel. It has a thermal coefficient of expansion greater than 27 x 10-6 per ºC (15 x 10-6 per °F). When combined with very low expansion alloys, this alloy promotes greater flexing due to the greater difference between the rates of thermal expansion.

In the bimetal strip thermostat, two strips of metals with different expansion coefficients are bonded together, either side by side, or layered. The strips may be joined by the application of pressure and/or heat treatment, and also by welding.

The unequal expansion rates of the two metals during temperature changes causes the strip to bend into an arc. This mechanical bending controls movement, as in the making and breaking of electrical contacts.

Parts are made by the billions for any function or process that is temperature controlled - i.e., thermostats to prevent overheating of electric motors, thermostats for circuit breakers in homes and industry, safety devices in home appliances, furnace controls, flow control devices, etc. These devices may act both as sensing elements and as active control components.

These differential expansion thermostats require the right match of high expansion and low expansion alloys. When the manufacturer knows how much movement is desired within an anticipated temperature range, he can design for the proper degree of deflection by considering the two alloy expansion rates.

Bimetallic device manufacturers generally specify the thickness and cross-section required in each material. The final component usually is composed of thin gage materials to allow for heat-responsive flexing when in contact with a circulating gas or liquid.

The iron-nickel-chromium high expansion alloys have good fabricability. They are compatible with the low expansion iron-nickel alloys when heat treating, welding and bonding.

Summary

Controlled expansion alloys are made by means of premium melting practice and specialized processing to achieve optimum properties. Control of grain size, for example, is important in the production of photoetch-quality parts and seals deep drawn from glass-sealing alloy strip.

The predictable success of modern fabrication processes depends largely on the carefully controlled physical, mechanical and expansion characteristics of these alloys. It is important that fabricators are aware of this intimate relationship between high-quality alloys and trouble-free production.

Controlled-expansion alloys are available in various standard forms - strip customized for either deep drawing, stamping, coining or forming; wire, bar and billets. Further, alloys may be customized to control properties such as chemistry, cleanliness, thermal expansivity and electrical resistivity.

***

By Leslie L. Harner

Carpenter Technology Corporation

Reading, PA

USA