Selecting Stainless Steels For Valves

Technical Guide

Technological advances in valve design and use over the past decade present interesting challenges today for those engaged in valve manufacturing and applications. Among these challenges is how to select the "best" material for components and a wide variety of end-use products.

More particularly, which of more than 400 commercially available stainless steels is the "right" one for a specific application, with newly introduced alloys constantly confusing the issue? The alloys pertinent to this discussion have been used typically in the industrial, chemical, petrochemical, pharmaceutical and semi-conductor industries.

While the selection process must focus on the steel’s properties and characteristics, the designer/engineer making the choice also knows that life-cycle costs, or the total cost over the equipment’s or product’s design life, is of bottom-line importance. The slightly higher cost of a more corrosion-resistant stainless steel, for example, may dwarf the total cost of settling for a next-best alloy. That’s because an unwise choice can be burdened with the additional cost of maintenance and replacement, plus the cost of lost production during equipment downtime.

Some newer valve applications, like the most stringent ones in the pharmaceutical and semi-conductor industries, limit material choice. For those critical applications requiring highly polished internal surfaces, the stainless steel selected must be premium melted to assure a super clean microstructure. Otherwise, parts that must be electro polished will be subject to pitting and failure that could be catastrophic in a production process.

Selection Criteria

Given this realistic value analysis, selection of the most suitable alloy should be based largely on five criteria. They are:

- Corrosion Resistance. Be sure to consider the environment and type of corrosion resistance to be encountered. The most cost effective stainless steel will have enough corrosion resistance to provide the required service life without the needless expense of over-alloying.

- Mechanical Properties. Strength is usually the most important mechanical property in the selection of a stainless steel. However, the designer may be concerned also with the alloy’s hardness, ductility, impact resistance, fatigue strength or stress rupture resistance – or, perhaps more than one of these properties. Furthermore, the potential effect of the desired mechanical property on the alloy’s corrosion resistance may be important.

- Physical Properties. These could include density or magnetic properties. For example, CarTech 22Cr-13Ni-5Mn (UNS S20910) stainless steel, which is non-magnetic in all conditions, may be preferred to CarTech 304 stainless steel, which may exhibit ferro-magnetic properties when cold worked.

- Fabrication. Will the component be machined, forged, cold formed or welded? The fabrication required should be considered from three perspectives: (a) How easy or difficult will it be to fabricate the component? (b) How will fabrication affect the alloy’s performance? (c) Will the quality of the alloy permit satisfactory fabrication?

- Final Component Cost. Do a thorough value analysis that includes the initial alloy price, the installed cost, and the effective life expectancy of the finished product.

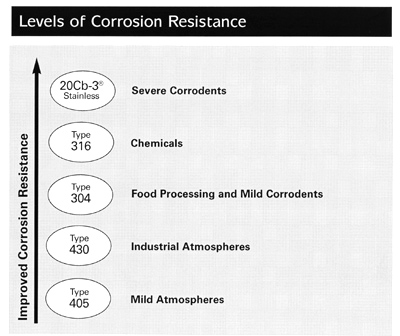

Corrosion Resistance

The Selectaloy® method, developed by Carpenter, is an effective means of selecting stainless steels. It begins with a determination of how much corrosion resistance is needed, and then factors in strength requirements for the specific application.

When looking for the right stainless steel, it is best to start with CarTech 304/304L stainless, the alloy specified more than 50% of the time whenever a stainless steel is used. It resists most oxidizing acids and general corrosion in many environments.

For greater corrosion resistance, move up to CarTech 316/316L stainless. This stainless is like CarTech 304, but with added molybdenum to boost its resistance to the attack of many industrial chemicals and solvents, and especially pitting caused by chlorides. A quality upgrade of CarTech 316 stainless known as CarTech Type 316L-SCQ® stainless has been found useful for valving in the semi-conductor industry where the components can be exposed to halide gases.

For more severe corrosion environments, CarTech 20Cb-3® stainless should be considered. This is a highly alloyed stainless steel that offers special resistance to sulfuric acid, and protection against loss of corrosion resistance from welding. It offers superior resistance to hundreds of industrial and process corrodents, especially in valved fluid piping systems.

There are many applications that require less corrosion resistance than that exhibited by the three grades mentioned. In those instances, CarTech 430 stainless, which is a less costly stainless alloy, may provide an adequate level of corrosion resistance. While it has less corrosion resistance than CarTech 304 stainless, it does resist foodstuffs, fresh water and non-marine atmospheric atmosphere.

For those applications requiring only the minimum resistance to corrosion, CarTech 405 stainless may be specified. It resists corrosion from soap, alcohol, crude oil, gasoline, mercury and other mild reagents.

The five stainless steels discussed so far are plotted in Figure 1 in order of increasing corrosion resistance. The basic CarTech 304 stainless is positioned in the middle.

Fig. 1 – Stainless steels in order of increasing corrosion resistance.

Mechanical Properties

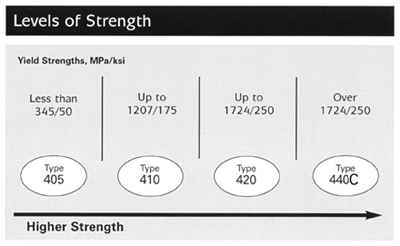

After the appropriate level of corrosion resistance has been ascertained, a careful study of mechanical properties is necessary to determine the proper alloy for an application. If low-level corrosion resistance to corrosion is adequate, but higher strength is required, CarTech 410 stainless should provide the service desired. CarTech 410 offers a wide range of mechanical properties, depending upon the tempering temperatures employed. It has been useful in applications demanding good strength, ductility and resistance to oxidation up to 649°C (1200°F).

For greater strength and hardness at the same level of corrosion resistance, CarTech 420 stainless may be considered. It has higher strength and wear resistance in the hardened and tempered condition than CarTech 410 stainless.

CarTech 440C stainless combines the lowest level of corrosion resistance with very high hardness and strength. This alloy may be considered for a broad range of products that require high hardness values and wear resistance.

The selection diagram has now been expanded to include, in Figure 2, the stainless grades with the lowest level of corrosion resistance, but with increasing strength moving left to right. In many valve applications, fluids must be regulated at different pressure levels. That is an application design factor that should be considered in finding a stainless with the right strength for the job.

Fig. 2 - Stainless steels in order of increasing strength.

For Greater Strength

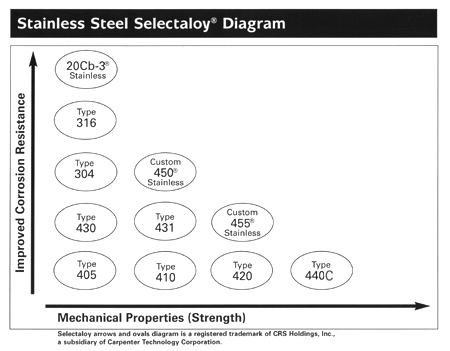

If greater strength is required, at a good level of corrosion resistance, move right on the chart directly opposite CarTech 430 to the thermally hardenable CarTech 431 stainless. With its good combination of corrosion resistance, toughness and hardness, this alloy may be considered for temperature applications between 73°C (-100°F) and 649°C (1200°F).

For highest strength at the second level of corrosion resistance, CarTech Custom 455® stainless (UNS S45500) is designated. This unique alloy can be used wherever a combination of high strength, good corrosion resistance, simple heat treatment and ease of fabrication is required.

CarTech Custom 450® stainless (UNS S45000) offers an unusual combination of formability and high strength, along with corrosion resistance that is unique for a material with 689 MPa (100 ksi) minimum yield strength. Its yield strength can be increased 50% through a simple, one-step, low temperature aging process without significantly decreasing the alloy’s corrosion resistance. The complete Selectaloy diagram is shown in Figure 3.

For greater strength requirements, a newer alloy known as CarTech Custom 465® stainless (UNS S46500), can be considered. This stainless, which would be positioned to the right of CarTech Custom 450 stainless in the diagram, is a premium melted, martensitic, age-hardenable alloy capable of ultimate tensile strength in excess of 250 ksi (1724 MPa) in the overaged (H950) condition. This alloy was designed to have excellent notch tensile strength and fracture toughness in this condition. Overaging to the H1000 condition provides a superior combination of strength, toughness and stress corrosion cracking resistance compared with other high-strength PH stainless alloys.

Fig. 3 – Selectaloy® diagram showing relative corrosion resistance and strength of 11 basic stainless steels.

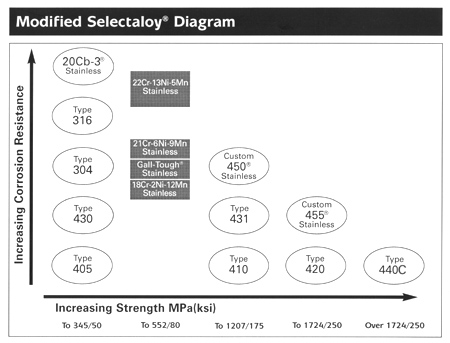

Nitrogen Strengthening Alloys

Many applications require a balanced combination of improved strength and corrosion resistance. When seeking greater strength with good corrosion resistance, the specifier should check the family of nitrogen-strengthened alloys shown in the modified Selectaloy diagram (Figure 4). All four have comparable mechanical properties, with yield strength of 345 MPa (50 ksi) to 414 MPa (60 ksi) as annealed, and strength levels in excess of 689 MPa (100 ksi) when cold worked.

These alloys are austenitic stainless steels with nitrogen added for improved strength and corrosion resistance. All of them, except CarTech Gall-Tough® stainless (UNS S20161), remain nonmagnetic even after severe cold working.

The group starts with the CarTech 18Cr-2Ni-12Mn stainless (UNS S24100), which has corrosion resistance similar to Type 430 stainless. It offers an excellent combination of toughness, ductility, corrosion resistance, strength and good fabricability. Farther up the scale are Gall-Tough stainless and CarTech 21Cr-6Ni-9Mn stainless (UNS S21904). These two grades can be considered for valve applications because they have corrosion resistance similar to that of Type 304 stainless with twice the yield strength and excellent high temperature strength.

CarTech Gall-Tough PLUS stainless (UNS S20162), a variation of CarTech Gall-Tough stainless, is a high-silicon, high-manganese, nitrogen-strengthened, austenitic stainless alloy that exhibits superior self-mated galling and metal-to-metal wear resistance. The alloy exhibits higher strength than CarTech 316. It also exhibits chloride corrosion resistance equal to or better than CarTech 316 stainless, along with equivalent high temperature oxidation resistance.

Fig. 4 – Modified Selectaloy® diagram with the addition of four nitrogen-strengthened stainless steels.

CarTech Gall-Tough stainless can be considered for applications such as valve, pump components and shafts where surface-to-surface friction is an issue. The CarTech 21Cr-6Ni-9Mn stainless may be considered also for valve applications requiring good corrosion resistance with superior strength characteristics.

The most corrosion resistant stainless in this family is the CarTech 22Cr-13Ni-5Mn grade. This alloy has better corrosion resistance than CarTech 316 stainless, and twice the yield strength. It provides high-level resistance to pitting and crevice corrosion and very good resistance in many reducing and oxidizing acids and chlorides.

Fabrication

After the stainless steel is selected on the basis of corrosion resistance and mechanical properties, it’s time to consider how the part or component is to be fabricated. The specifier may want to improve fabrication characteristics by using a modification of the alloy chosen. There are many modifications of the 15 basic stainless steels mentioned, with individual and distinctive fabrication properties. Each has a different name or type number depending on its chemical analysis, and each constitutes an addition to the growing family of stainless steels.

Suppose, for example, we have chosen the basic CarTech 304 stainless for an application, and anticipate a difficult machining problem. Although CarTech 304 stainless can be machined, other variations of the alloy have better machinability.

Two other members of the group offer better machinability. In order of improving machinability, they are CarTech 304 stainless Project 70+® stainless and CarTech 303 Project 70+ stainless. In addition, CarTech 316 Project 70+ stainless offers the superior corrosion resistance of its conventional counterpart, along with improved machinability.

As the designer or engineer moves about within the fabrication families, searching for a suitable alloy modification, it is important to note that reaching the ultimate material for one fabrication process is achieved at some loss in other fabrication qualities. For example, as machinability improves, the more likely the alloy’s cold working characteristics will decline.

Summary

Several key factors should be considered in selecting the most suitable stainless steel for any use. First, with the diagram provided, select the level of corrosion resistance required. Second, choose the level of strength needed. Third, consider the type and amount of fabrication necessary; then select the alloy modification which offers the most desirable fabricating characteristics.

Do a thorough value analysis, which includes the initial alloy price, the installed cost and the effective life expectancy of the finished product. Finally, determine the availability of the preferred alloy from the steel mill, service center, warehouse or supplier to arrive at the most economical and practical choice.

***

By Ralph Vedder, Staff Specialist, Bar Technical Services

Carpenter Technology Corp., Reading, PA, USA