Two Precipitation-Hardenable Steel Alloys Developed for Use in Aerospace

White Papers

Two Precipitation-Hardenable Steel Alloys Developed for Use in Aerospace Applications

Carpenter Technology solidified its commitment to the high-performance jet age through significant investments in electro-slag remelting, forging, and finishing technologies. Precipitation-hardenable (PH) stainless steels are turning up in more and more aerospace applications because they can be age hardened, sometimes after being cold worked, to various strength levels, and used in severe environments. Two in particular, Custom 465® stainless and Project 70+® 15Cr-5Ni alloy, offer competitive advantages in strength and machining that could be useful in any industry that uses steel.

Custom 465® Stainless

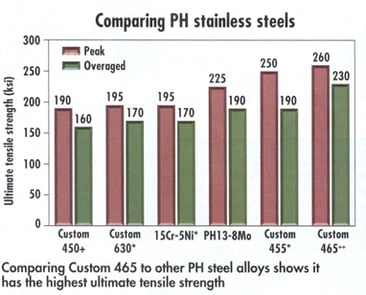

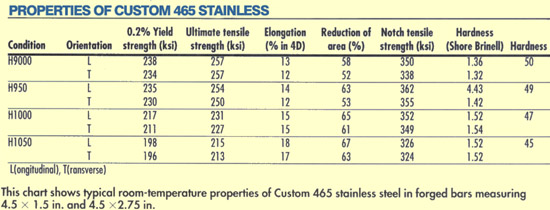

Custom 465 stainless (S46500) is among the strongest of all commercially available PH stainless alloys. Its ultimate tensile strength in the H950 condition is about 255 ksi (1,758 MPa). In this condition, it still has high notch tensile strength and fracture toughness. It was developed in response to demands from the aerospace industry for materials that will keep aircraft flying for 30 years or more with minimum maintenance. It has been used for structural components such as flap tracks, actuators, engine mounts, and landing-gear hardware.

Custom 465 stainless is a melted, martensitic stainless steel with strength and fracture toughness that resists stress-corrosion cracking better than other high-strength PH alloys. Its chemical composition is: carbon 0.02% max., manganese 0.25% max., phosphorus 0.015% max., sulfur 0.01% max., silicon 0.25% max., chromium 11 to 12.5%, nickel 10.75 to 11.25%, titanium 1.5 to 1.8%, molybdenum 0.75 to 1.25%, the balance is iron. Aging the alloy to H950 through H1000 conditions brings out its strength and is suggested for most applications.

In general, Custom 465 is less sensitive to process parameters than other high-strength PH steels. Its relatively low annealed yield strength, along with a low cold-work hardening rate, make the alloy well suited for making fasteners and drawing small-diameter wires. Custom 465 stainless can be cold drawn in excess of 90% reduction, with no intermediate anneal. On the other hand, drawn and aged Custom 465 wire’s strength is over 300 ksi (2,070 MPa). The alloy is also thermally stable after long-term exposure to elevated temperatures.

Custom 465’s corrosion resistance approaches that of Type 304 stainless. Tests show that exposure to 5% neutral salt spray at 95°F (35° C) (per ASTM B117) causes little or no rusting after 200 hr., regardless of aging. Double-cantilever-beam tests conducted in 3.5% NaCl (pH 6) at room temperature showed overaged Custom 465 has good resistance to stress corrosion cracking (SCC). And its SSC resistance improves as aging temperatures increase. By comparison, Custom 465 is significantly stronger than PH 13-8 Mo* and Custom 455® alloys formulated with the same SSC resistance. Comparing these alloys when heat treated to the same longitudinal fracture toughness (100 ksi (in.1/2) or 110 Mpa (m1/2)), their yield strengths rank as follows: Custom 465 stainless at 230 ksi (1,585 MPa), PH 13-8 Mo at 205 ksi (1,413 MPa), and Custom 455 at 200 ksi (1,380 MPa).

To make Custom 465 resist chloride, metalworkers age it at 950°F (510°C) or higher. The resulting metal is stronger than other PH steels with high levels of chloride resistance. Indeed, the ultimate tensile strength of Custom 465 exceeds that of any commercial PH steel aged between H900 and H1150.

Custom 465 stainless is fully solution annealed when held for 1 hr at 1,800°F (982°C) ±15°F, then rapidly cooled and annealed at -100°F. Cold treating it at 100°F reduces the sensitivity of the aged properties to prior processing.

Custom 465 is strengthened by holding it at a selected temperature between 900 and 1,150°F (482 to 621°C) for 4 hr then cooling it in ambient air. The choice of aging temperature depends on what combination of strength, toughness and SCC resistance is needed. The flexibility that aging gives this alloy, along with the corresponding range in properties, make it a candidate for applications within and beyond the aerospace industry.

Cold working Custom 465 then aging it at 900°F (482°C), for example, gives it maximum strength of over 300 ksi for parts with diameters less than 0.75 in. This is useful for making surgical and dental instruments and needle wire for the medical industry. With the right combination of strength, hardness, and toughness, the material can be used for cutting edges on hand tools, and for tool bodies themselves.

Engineers could use Custom 465 to upgrade cadmium and chromium plated steel-alloy parts. It might also be a replacement for components made of 15Cr-5Ni and Custom 630 (17Cr-4Ni) PH steels that need more strength, a smaller size, or lower weight.

* PH 13-8 Mo is a registered trademark of AK Steel Corp.

Project 70+® Stainless

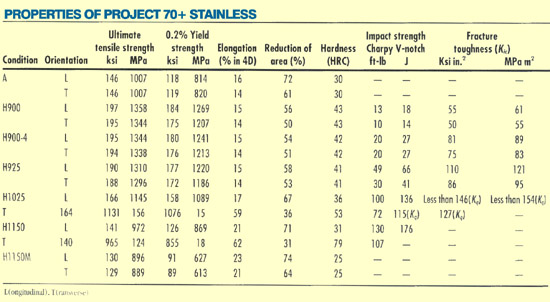

A while back, many shops making parts from 15Cr-5Ni couldn’t keep pace with production schedules because of the material’s relatively poor machinability. Its machining properties were improved by modifying its composition and keeping in mind the relationship between chemistry and modern steel-processing methods. The result was Project 70+ 15Cr-5Ni, a significant improvement on and drop-in replacement for conventional 15Cr-5Ni stainless, a steel alloy used for decades in aerospace. Project 70+ stainless meets all aerospace composition, corrosion resistance, and mechanical requirements, including Aerospace Materials Specification 5659 covering bars, wire, forgings, rings, and extrusions, and ASTM A564.

Project 70+ stainless, a vacuum remelted, precipitation-hardening, martensitic stainless steel, lets shops push machining speeds and feeds to higher levels. Machinability can be further improved with assistance from the alloy developer. But even without technical assistance, shops trying out the alloy can begin machining at their own comfort level, then ramp up to find out how much cycle times can be reduced and tool times extended.

In addition to improved machinability, the alloy can be headed, rolled, and otherwise formed by cold working. And it can be forged by uniformly heating work pieces at between 1,950 and 2,050°F (1,066 to 1,121°C) for 1 hr before forging in accordance with a recommended schedule. Project 70+ can also be shield-fusioned and resistance welded.

The alloy’s corrosion resistance approaches that of 304 stainless, and is similar to Carpenter Technology’s 15Cr-5Ni and Custom 630 (17Cr-4Ni) stainless steels. It resists SSC after age hardening at temperatures of 1,025°F (552°C) and higher. The alloy also resists oxidizing to approximately 1,100°F (593°C). Higher aging temperatures improve toughness and ductility with decreasing strength.

Like conventional 15Cr-5Ni, Project 70+ stainless shows little or no rusting after 200 hr of exposure to ASTM B117’s salt-fog test when solution-annealed or age-hardened at temperatures from 900 to 1,150°F (482 to 621°C). However, optimal corrosion resistance requires chemical passivation. Both nitric acid and citric acid treatments are suitable.

It is worth noting that in H925 condition, Project 70+ stainless can have excellent longitudinal and transverse fracture toughness and meet frequently specified 180 to 200-ksi ultimate tensile strength requirements. Due to the alloy’s homogeneity, there is little difference between longitudinal and transverse properties.

Analysis shows Project 70+ stainless is comprised of: carbon 0.07% max., manganese 1% max., phosphorus 0.03% max., sulfur 0.015% max., silicon 1% max., chromium 14 to 15.50%, nickel 3.5 to 5.5%, molybdenum 0.5% max., copper 2.5 to 4.5%, columbium 0.15 to 0.45%, tantalum 0.05% max., iron makes up the balance.

In one highly successful application, Sturm Ruger & Co., Inc., Southport, Conn., used Project 70 to replace conventional 15Cr-5Ni for the barrel of its Super Redhawk .454 Casull, one of the most powerful commercially available revolvers in the world. Conventional 15Cr-5Ni stainless steel met design requirements for strength and corrosion resistance, but was difficult to machine. It took Ruger 28 min. to gun drill a 0.480-in.-diameter hole in a 1-in. OD x 19-in. long bar at the rate of 0.71 ipm. (The bars are later hammer-forged over a mandrel and cut into three 7-in.-long gun barrels.) After switching to Project 70+, gun drilling cycle times went down by 20% and tool life increased. And CarTech Project 70+ stainless’s transverse mechanical properties let the barrels resist the high stresses produced by the cartridge fired through them.

Other results with aerospace applications have been equally impressive. One manufacturer improved productivity by 145% for machining a part that required milling, boring, turning, drilling, and thread rolling. Another company, doing a simple turning operation, cut cycle times by a third and increased tool life by 50%. Still, another parts producer, in milling Project 70, tripled speeds and feeds, and increased cut depth by a factor of 5 without burning the cutting tools.

An aircraft shock strut is made of Carpenter Technology's Project 70+ stainless steel, which is easier to machine than conventional 15Cr-5Ni steel.

Project 70+ 15Cr-5Ni stainless can reduce machining times.

Speeds and Feeds for Machining Project

For single-point and box tools

|

High-Speed Tools |

Carbide Tools |

|||||||

|

Cut depth (in.) |

Tool |

Speed |

Feed |

Tool |

Speed (fpm) |

Feed |

||

|

SOLUTION TREATED |

||||||||

|

0.15 |

M2, T15 |

110 |

0.015 |

C6 |

310 |

340 |

440 |

0.019 |

|

0.025 |

M2, T15 |

125 |

0.01 |

C7 |

240 |

290 |

390 |

0.009 |

|

AGED |

||||||||

|

0.15 |

T15,M42 |

85 |

0.013 |

C6 |

190 |

240 |

340 |

0.013 |

|

0.025 |

T15,M42 |

105 |

0.008 |

C7 |

240 |

290 |

390 |

0.006 |

For cut-off and form tools

|

Tool Material |

Speed |

Feed (IPR) |

|||||||

|

Cut-off tool width (in.) |

Form tool width (in.) |

||||||||

|

High-Speed |

Carbide |

0.0625 |

0.125 |

0.25 |

0.5 |

1 |

1.5 |

2 |

|

|

SOLUTION TREATED |

|||||||||

|

T15 |

80 |

0.0017 |

0.002 |

0.0025 |

0.0028 |

0.0022 |

0.0019 |

0.0017 |

|

|

C6 |

260 |

0.0021 |

0.0024 |

0.0029 |

0.0032 |

0.0024 |

0.0021 |

0.0019 |

|

|

AGED |

|||||||||

|

T15 |

70 |

0.0014 |

0.0017 |

0.0022 |

0.0025 |

0.0019 |

0.0016 |

0.0014 |

|

|

C2 |

240 |

0.0016 |

0.0019 |

0.0024 |

0.0027 |

0.002 |

0.0017 |

0.0015 |

|