consumer

Electronics

Performance to Drive Consumer Preference

For the next generation of cellphones, wearables, hearing aids, and other consumer electronics, advanced features and performance drive customer preferences. Our material solutions provide development flexibility to help you meet rapid new product development cycles with soft magnetic alloys that provide unique performance advantages.

APPLICATION SPOTLIGHT

Electronics

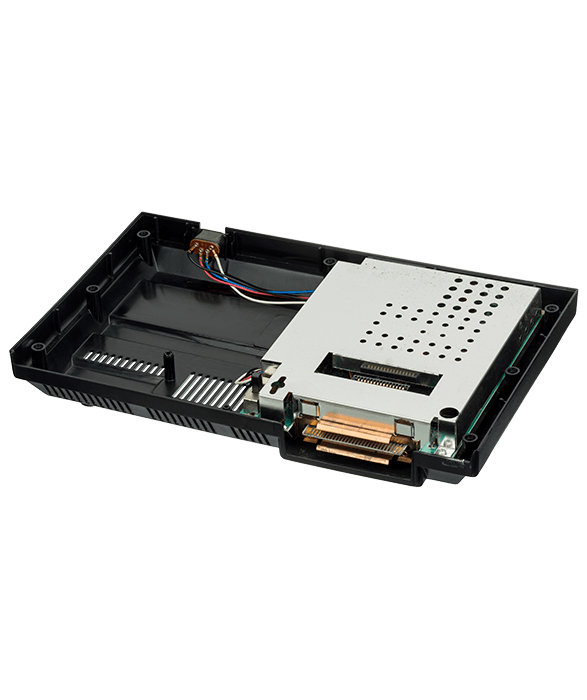

Haptic and Sensor Shielding

High permeability alloys and laminated stacks act as current sensors and prevent unwanted electromagnetic interference between adjacent devices in compact consumer electronic applications.

FEATURED PRODUCTS

none

HyMu80

80% nickel-iron-molybdenum alloy with extremely high initial and maximum permeability, minimum hysteresis loss, and low coercivity

none

High Permeability 49

High initial and maximum permeability for fast magnetic response and low core loss after heat treatment that can be readily stamped

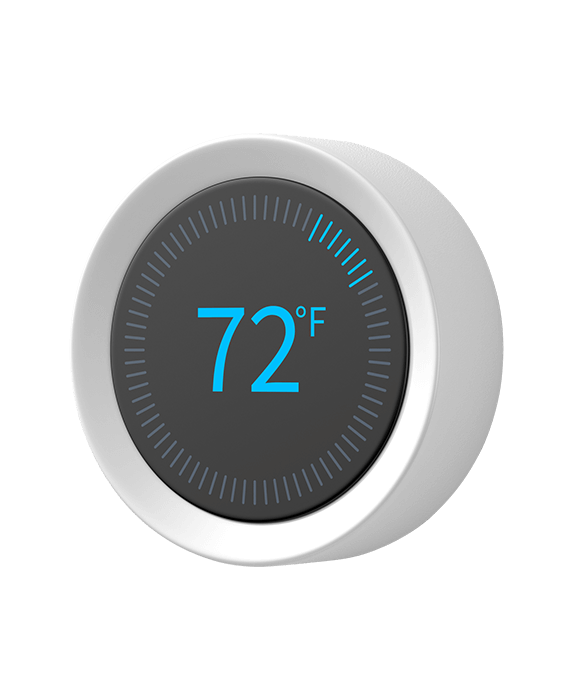

Haptic Engines and Motors

Haptic feedback requires precise motor responses to simulate a range of tactile feedback. Our high induction and permeability alloys offer higher force, improving the haptic device sensitivity and power consumption.

FEATURED PRODUCTS

none

Hiperco® 50A

Highest magnetic saturation with low coercivity and the lowest losses with mechanical properties that can be tailored to optimize power dense motors

none

Hiperco® 27

A ductile-high-magnetic saturation and high-induction alloy

none

A-286

Iron-base austenitic stainless steel with notched rupture strength superior to any other alloy with comparable high-temperature properties

Microspeakers

Progress in miniaturization of electronics requires smaller micro speakers with higher audio output. We work with designers to build smaller, lighter transducers with similar power levels, or create more powerful transducers of a similar size.

FEATURED PRODUCTS

none

Hiperco® 27

A ductile-high-magnetic saturation and high-induction alloy

none

Hiperco® 50A

Highest magnetic saturation with low coercivity and the lowest losses with mechanical properties can be tailored to optimize power-dense motors

Thermal Expansion

Alloys with controlled expansion characteristics are used for a broad variety of applications where thermal size change of the metal must be considered in component part design.

FEATURED PRODUCTS

none

Invar 36

36% nickel-iron alloy possessing a rate of thermal expansion approximately one-tenth that of carbon steel at temperatures up to 400°F (204°C)

none

Free-Cut Invar "36"®

Free-machining 36% nickel-iron alloy possessing a rate of thermal expansion approximately one-tenth that of carbon steel at temperatures up to 400°F (204°C)

Glass Sealing

Glass-to-metal sealing applications require specialty alloys designed to match the rate at which glasses cool from various elevated temperature ranges. Our materials offer lasting metal-to-glass fusion in hermetically-sealed devices.

FEATURED PRODUCTS

none

Kovar

Vacuum melted, iron-nickel-cobalt, low expansion alloy with a controlled chemical composition for precise uniform thermal expansion to make a strong hermetic seal

none

Glass Sealing 27

Ductile 28% chromium-iron alloy exhibiting no phase transformation up to 2100°F (1150°C) and particularly adapted to outside sealing

none

Glass Sealing 42

41% nickel-iron controlled expansion alloy can be used for a variety of hard glass with thin edge tubular seals

Better Products Faster

Solutions must be small and lightweight but also provide expanded functionality, and in certain applications must have stable operation across a wide range of temperatures.

Whether it's diverse soft magnetics, application engineering, product knowledge, rapid prototyping and sampling, or other performance solutions, our expertise will get you to market with better products faster.

Related Resources

Browse our growing library of resources for the market including case studies, product brochures, technical data sheets, product selection guides, and more.