defense

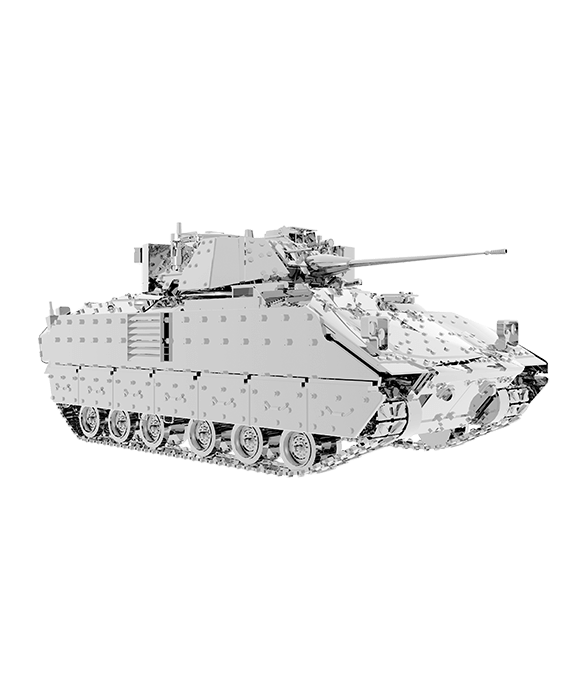

Armored Vehicles

Stronger, Tougher, More Powerful Metallurgy for the Warfighter

Defense OEM’s trust our metallurgical experts to develop and deliver tougher, stronger, more powerful, and corrosion-resistant materials for combat vehicles that enable affordable speed, reach, lethality, and survivability. We have been providing specialty metals innovation to the warfighter from world-class domestic specialty metals mills for over 100 years.

APPLICATION SPOTLIGHT

Armored Vehicles

Structural Alloys

For demanding applications such as torsion bars, small fixed craft landing gears, or components requiring high temperature resistance, we offer metallurgical innovations for high-strength, toughness, and fatigue in extreme environments.

FEATURED PRODUCTS

none

300M

A modified 4340 steel possessing high hardenability and impact strength while being lightweight

none

4340

Low alloy, nickel-chromium-molybdenum steel with ductility and toughness, capable of being heat treated to high strength levels

none

Custom 465®

Best-in-class high-strength stainless steel with improved notch tensile strength, fracture toughness, and fabricability with excellent resistance to stress corrosion cracking

none

AerMet® 100

High hardness and strength combined with exceptional ductility, high fracture toughness, and exceptional stress corrosion cracking resistance

none

D6AC

High-strength steel with good toughness and high temperature resistance, high yield strength to tensile strength ratio, and good ductility

Auxiliary Power Units (APUs)

High-performance materials enable the design of smaller, lightweight motors and lightweight instrumentation without compromising on performance. Our materials enable the most power-dense, smallest, and lightest generators and APUs.

FEATURED PRODUCTS

none

Hiperco® 50A

Highest magnetic saturation with low coercivity and the lowest losses and mechanical properties that can optimize power dense motors and generators

none

Hiperco® 50

Highest magnetic induction and low losses with mechanical properties that can meet both stator and rotor application needs

none

Hiperco® 50HS

Highest magnetic saturation with high yield strength and moderate core loss and mechanical properties that can optimize power-dense motors

none

Hypocore®

Combination of high magnetic induction and low losses for higher continuous power with low cobalt composition and low coercivity

Work with Carpenter Technology to improve your product and your process.

We develop new materials that can meet or exceed your design parameters and help you achieve performance breakthroughs. This allows you to design smaller and/or lighter parts with materials that avoid fatigue or fracture. These lighter components can improve performance, increase operating hours and reduce field failures.

Related Resources

Browse our growing library of resources for the market including case studies, product brochures, technical data sheets, product selection guides, and more.