energy

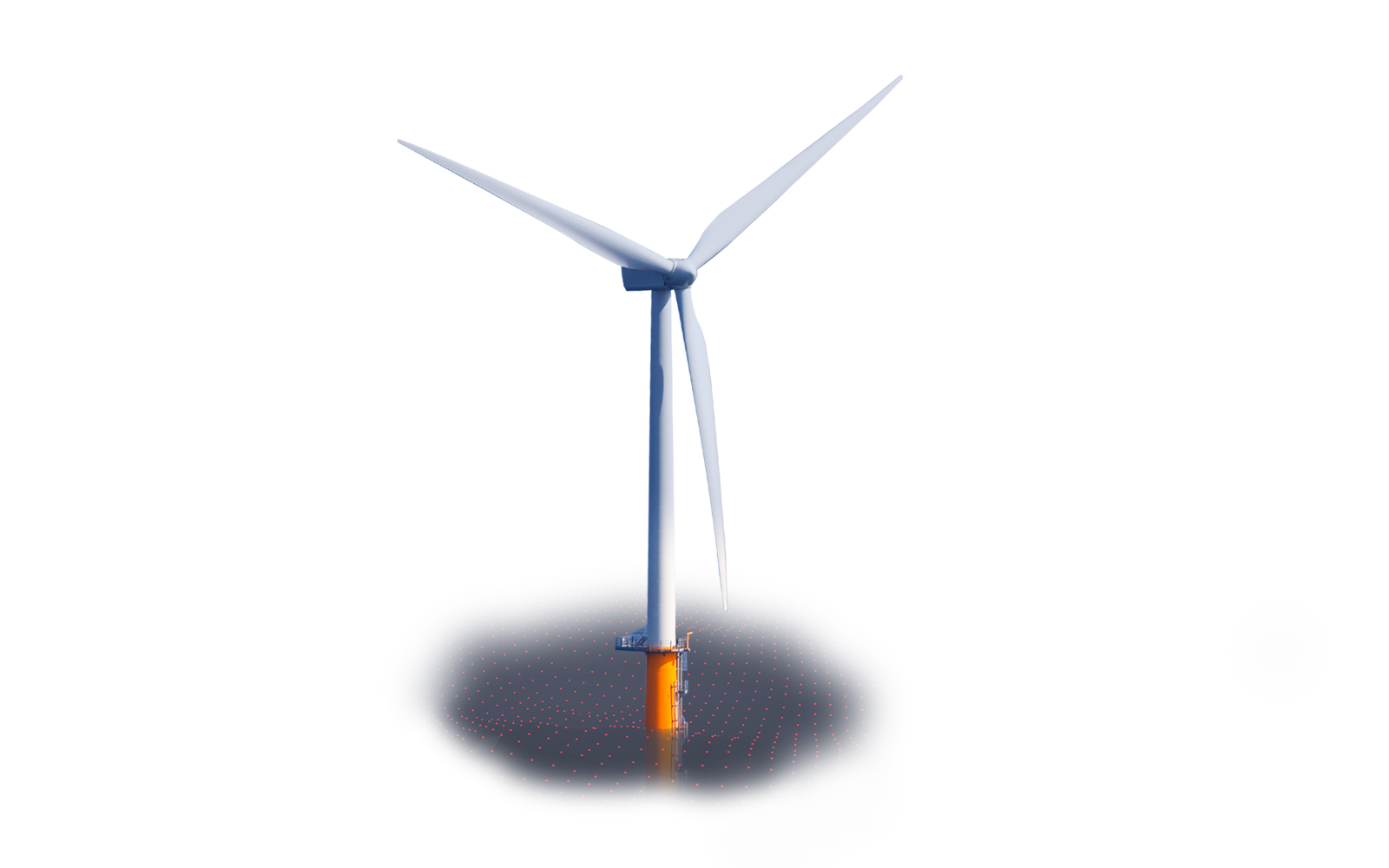

Offshore Wind Energy

The Drive to New Technology Brings New Challenges

Wind power is an increasingly important source of electricity and in remote ocean and salt spray environments where operational performance measured in MTTR and MTBF is essential. The selection of materials with corrosion resistance and longevity is vitally important. Industry-wide, as operational maintenance costs and lifecycle requirements increase, the dependability and durability of components are essential. Our materials are tailored to provide unique solutions for electrical and mechanical components in wind turbines.

APPLICATION SPOTLIGHT

Offshore Wind Energy

Drive Shaft

Transmitting mechanical power from the turbine blades to the generator, drive shafts are mission critical and must handle transient loads during startup, shutdown, emergency stops, and grid connections.

FEATURED PRODUCTS

none

A-21®

Carburizable and nitridable stainless steel with superior corrosion resistance, fatigue life, and fracture toughness with high yield strength. Hard, corrosion resistant carburized case, ductile core

none

PremoMax®

Premium alloy steel with a combination of high strength, excellent impact and fracture toughness, and carburized surface hardness

none

Custom 465®

High-strength stainless steel with corrosion resistance, high strength and superior fracture toughness to withstand high torque loads in harsh environments for extended periods of time

none

Fine-Grain 718

Nickel-base alloy offering exceptionally high yield strength and fatigue life with superior corrosion resistance

Gearboxes

Gearbox components require high strength and damage tolerance with high surface hardness to transmit mechanical power and torque loads from turbine blades to the generator for grid synchronization.

FEATURED PRODUCTS

none

Pyrowear® 53

Carburizable alloy for good wear resistance, toughness, and fatigue performance

none

PremoMax®

Premium combination of high strength, excellent impact and fracture toughness, and carburized surface hardness

none

A-21®

Carburizable and nitridable stainless steel with superior corrosion resistance, fatigue life, and fracture toughness with high yield strength. Hard, corrosion resistant carburized case, ductile core

none

ACUBE® 100

Non-magnetic cobalt-base alloy with superior galling resistance with moderate strength and high toughness

Bearings

Critical components support rotating equipment and must carry thrust loads created by blade drag. Materials used require high surface hardness, core strength, and core toughness, with corrosion, cracking, and galling resistance.

FEATURED PRODUCTS

none

Pyrowear 53®

Carburizable alloy for good wear resistance, good toughness and good fatigue performance

none

PremoMax®

Premium combination of high strength, excellent impact and fracture toughness, and carburized surface hardness

none

M-50

High carbon steel with good wear resistance and fatigue performance

none

A-21®

Carburizable and nitridable stainless steel with superior corrosion resistance, fatigue life, and fracture toughness with high yield strength. Hard, corrosion resistant carburized case, ductile core.

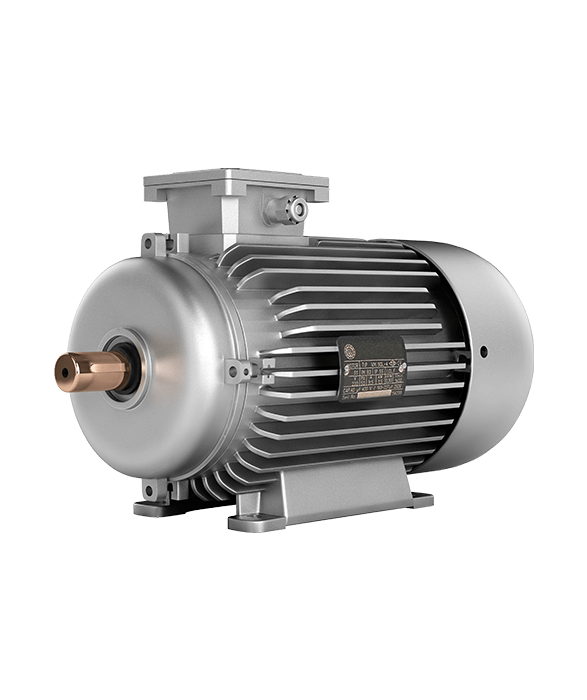

Generators

The high costs of installation and maintenance required for offshore wind turbines necessitate maximized power output from each unit. Our soft magnetic alloy portfolio features high permeability and saturation combined with low coercivity to enable more efficient power generation leading to increased revenue per unit.

FEATURED PRODUCTS

none

Hiperco® 50

Soft magnetic alloy with high saturation. Substantial efficiency upgrade to Fe-Si steels with higher power-to-weight ratio and lower MTBF. Relatively high yield strength for stator laminations and rotor components

none

Hiperco® 27

A ductile, high-magnetic-saturation, and high-induction alloy delivering high power density

none

Hypocore®

Combination of high magnetic induction and low losses for higher continuous power with low cobalt composition and low coercivity. Some performance is traded in exchange for lower cost

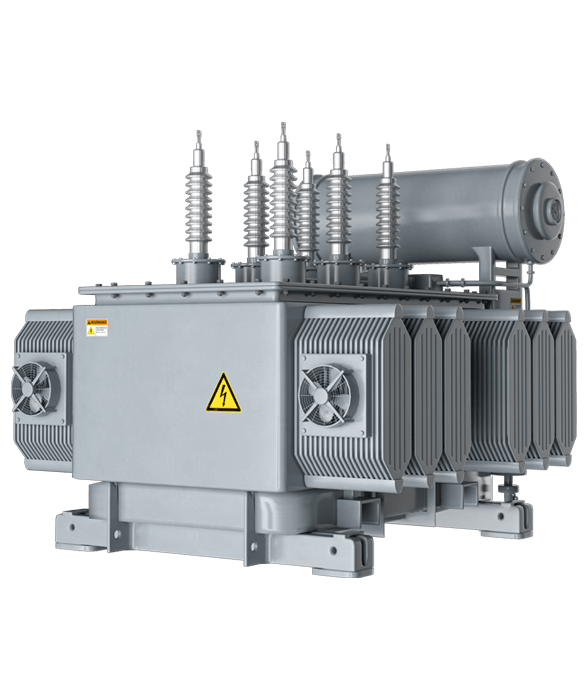

Transformers

Offshore turbines use transformers to step up voltage for intermediate transmission and inland substations further increase voltage for long-range transmission. Efficient soft magnetic alloy solutions minimize energy loss during long-range power transmission.

FEATURED PRODUCTS

none

High Permeability 49

High initial and maximum permeability for fast magnetic response, low coercivity, and good resistivity

none

HyMu 80

80% nickel-iron-molybdenum alloy with extremely high initial and maximum permeability, minimum hysteresis loss, and low coercivity

Gears

Yaw control and blade pitch gears are mission-critical components that require high-strength material solutions to transmit torque loads.

FEATURED PRODUCTS

none

Pyrowear 53®

Carburizable alloy for good wear resistance, good toughness and good fatigue performance

none

PremoMax®

Premium combination of high strength, excellent impact and fracture toughness, and carburized surface hardness

none

A-21®

Carburizable and nitridable stainless steel with superior corrosion resistance, fatigue life, and fracture toughness with high yield strength. Hard, corrosion resistant carburized case, ductile core

none

ACUBE® 100

Non-magnetic cobalt-base alloy with superior galling resistance with moderate strength and high toughness

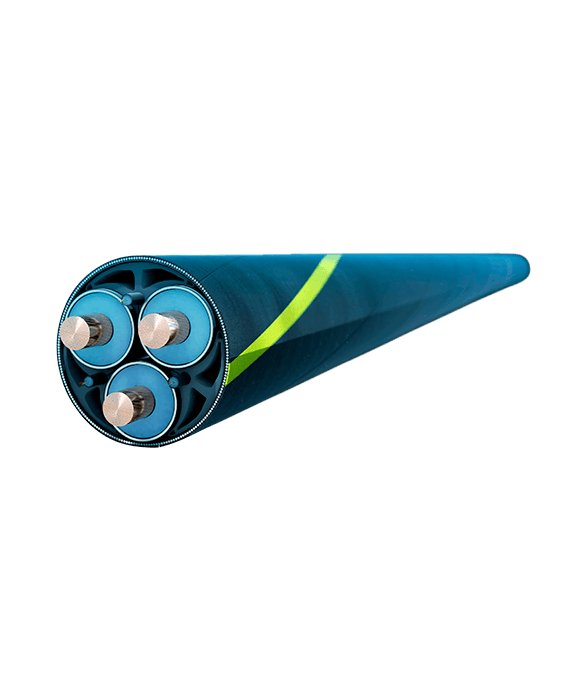

Subsea Umbilical Cables

To transmit power from turbines to offshore substations and further onshore, conductors and fibers must be encased in strong metal tubing with corrosion resistance.

FEATURED PRODUCTS

none

316

Austenitic stainless steel with corrosion resistance with higher tensile and creep strength

none

2205

Duplex stainless steel microstructure consisting of austenite and ferrite phases offers excellent strength and corrosion resistance

none

2507

Duplex stainless steel with a good combination of strength, corrosion resistance, and toughness

Work with Carpenter Technology to improve your product and your process.

From supply reliability to providing trusted advice, we are sought after by the technical community to solve problems and deliver increased efficiency, reliability, and cost-effectiveness through superior material performance with reduced environmental impact.

Related Resources

Browse our growing library of resources for the market including case studies, product brochures, technical data sheets, product selection guides, and more.