industrial

Infrastructure

Consistent Performance Through Quality Materials

Our expert metallurgists continue to make advancements in high-quality iron-, nickel-, cobalt-, and titanium-based specialty alloy engineering. Combined with comprehensive melting, remelting, forging, hot rolling, cold rolling, and heat treating capabilities, infrastructure projects benefit from materials that are able to withstand extreme corrosion, pressure, thermal variation, and stress.

APPLICATION SPOTLIGHT

Infrastructure

Stainless Steel Rebar

Minimize lifecycle costs with a reliable solution to address rebar corrosion and minimize bridge and structure repairs.

FEATURED PRODUCTS

none

EnduraMet 32

A non-magnetic, low-nickel, nitrogen-strengthened austenitic stainless steel with high yield and tensile strength

none

EnduraMet 2304

A lean duplex stainless steel with austenite and ferrite phases offering an excellent combination of strength and corrosion resistance

none

316LN

A non-magnetic, low austenitic stainless steel commonly used for MRI chamber construction

Revetment Wire

Partner with us for materials providing a protective overcoat to shield riverbanks from erosion and sloughing caused by turbulent water and flooding.

FEATURED PRODUCTS

none

201 Modified

A low-nickel, austenitic stainless with considerably higher tensile and yield strengths in the annealed condition, while being corrosion resistant

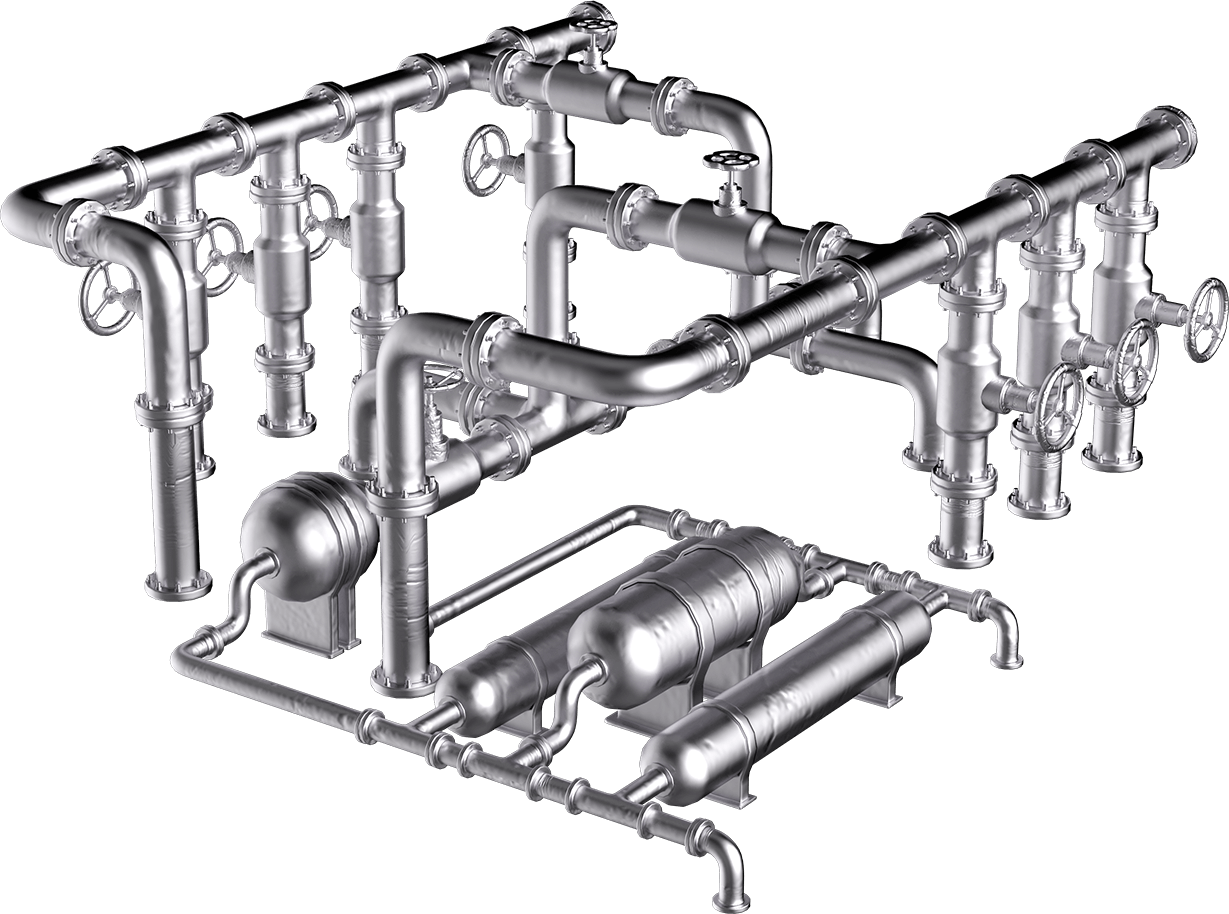

Municipal Water Systems

We supply American made materials for critical applications. Our diverse portfolio of materials can meet exacting standards, ensure safety and dependability while lowering the project cost.

FEATURED PRODUCTS

none

302HQ

Low work-hardening, austenitic stainless steel resistant to atmospheric corrosion and a wide variety of inorganic chemicals

none

316L

Formable and machinable austenitic stainless steel with excellent corrosion resistance

none

Custom 630 (17Cr-4Ni)

Martensitic precipitation, age-hardenable stainless alloy offering high strength and hardness, excellent corrosion resistance, and good fabricating characteristics

Turn to Carpenter Technology for consistency.

From our technical expertise and customer service to the reliable performance of our materials, we partner with companies prepared to solve challenges with a broad portfolio of engineered solutions. Our materials are recognized throughout the industry for their quality. We offer a diverse selection of materials to support multiple offerings for strength, wear, and corrosion resistance that meet exacting standards to give you a critical competitive advantage.

Related Resources

Browse our growing library of resources for the market including case studies, product brochures, technical data sheets, product selection guides, and more.