industrial

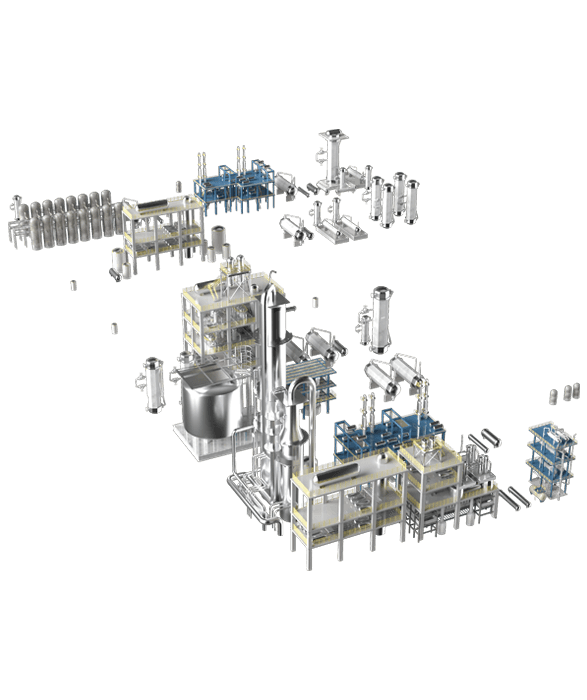

Process Systems

The Highest Quality Materials, Bar None

Our customers produce the highest-quality, differentiated components used in critical process control equipment. We help make this happen with materials that meet exacting standards for high consistency and cleanliness. Our state-of-the-art testing capabilities ensure that our materials consistently meet the most exacting standards, providing you with greater security and efficiency in your manufacturing process. We set the industry standard for high purity requirements to avoid dangerous in-service failures and cross-contamination.

APPLICATION SPOTLIGHT

Process Systems

Semiconductor

Avoid in-service failures and cross-contamination with our industry-leading, high-purity materials to reliably manufacture high-value integrated circuits with tight acceptance criteria.

FEATURED PRODUCTS

none

316L-SCQ

VAR processed derivative of 316L stainless with similar corrosion resistance, machinability, weldability, and improved electropolishing characteristics

none

Conichrome®

A high-strength, corrosion-resistant Nickel-Cobalt-Chromium-Molybdenum alloy that provides exceptional fatigue performance with low stress relaxation

none

Super Invar 32-5

A magnetic, austenitic, solid solution alloy containing iron, nickel and cobalt designed for exceptional temporal and thermal stability

Chemical Processing

Avoid expensive downtime and capital expenses with a selection of materials from a diverse portfolio to meet any requirement.

FEATURED PRODUCTS

none

625

Solid-solution-strengthened nickel-base alloy with outstanding strength and toughness from cryogenic to 2000°F (1093°C) with excellent fatigue strength and stress-corrosion cracking resistance to chloride ions

none

Ni-Cu 400

A nickel-copper solid solution binary alloy combining high strength and toughness over a wide temperature range with excellent resistance to many corrosive environments

none

2507

A duplex stainless steel with a good combination of excellent strength, corrosion resistance, and toughness for demanding applications

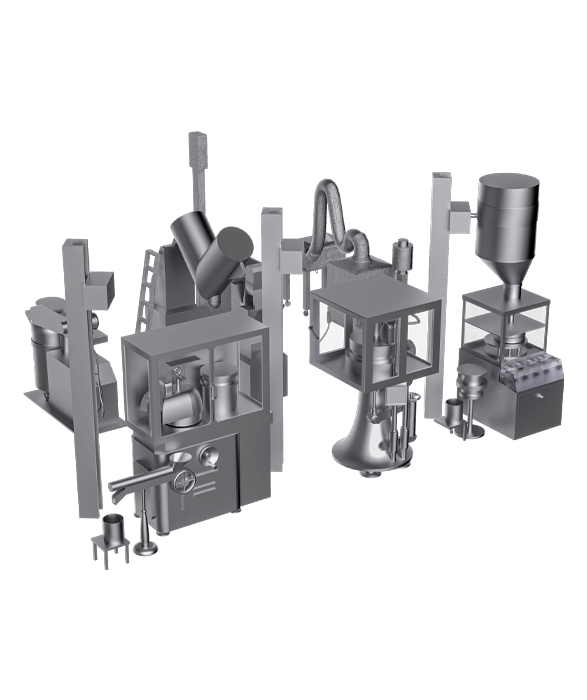

Food and Beverage

Food processing machinery must meet the highest standards. Our solutions help ensure peak performance of high wear food contact parts, from cutting and mixing blades, to extruder parts and gears.

FEATURED PRODUCTS

none

316 Project 70®+

An improved-machining version of conventional 316/316L shown to minimize carbide precipitation during welding

none

PYROMET® 41

Nickel-base, precipitation-hardening alloy that exhibits high strength in the 1200/1800°F (649/982°C) temperature range

none

CTS® XHP

Proprietary air hardening, high carbon, high chromium, corrosion resistant alloy with superior edge retention and surface finish with consistent heat-treatability

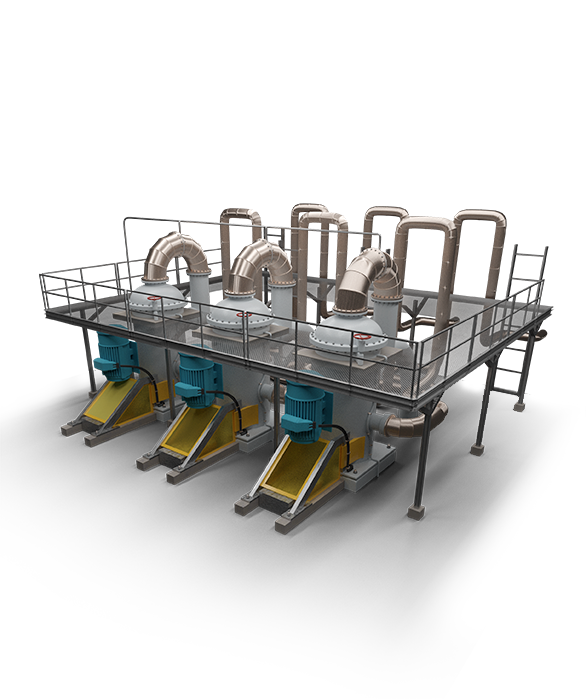

Pulp and Paper

As processes become more aggressive and maintenance intervals extend, we provide material support to transition to higher grades with superior corrosion resistance in severe conditions.

FEATURED PRODUCTS

none

625

Solid-solution-strengthened nickel-base alloy with outstanding strength and toughness from cryogenic to 2000°F (1093°C) with excellent fatigue strength and stress-corrosion cracking resistance to chloride ions

none

825

Nickel-base alloy with excellent resistance to many aggressive environments and superior resistance to chroride-ion stress-corrosion cracking

none

2507

A duplex stainless steel with a good combination of strength, corrosion resistance, and toughness

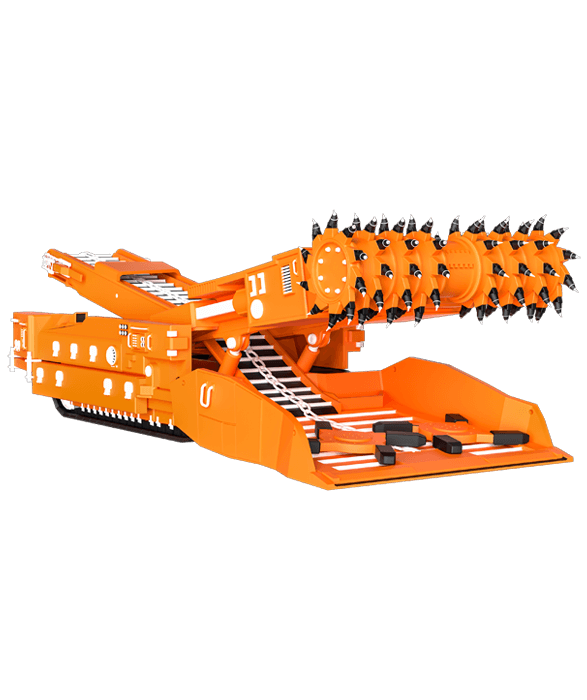

Mining

Minimize expensive downtime, repair, and overhaul with our novel material solutions that solve long-standing industry challenges.

FEATURED PRODUCTS

none

A-21®

Carburizable and nitridable stainless steel with superior fatigue and fracture toughness and relatively high yield strength with improved heat-check resistance

none

PremoMax®

Carburizable alloy steel with an exceptional combination of strength and toughness which can achieve a 60HRC surface hardness

Pharmaceutical

Avoid in-service failures and cross-contamination with our corrosion-resistant alloy solutions and industry-leading, high-purity materials suitable for electropolishing to exacting standards.

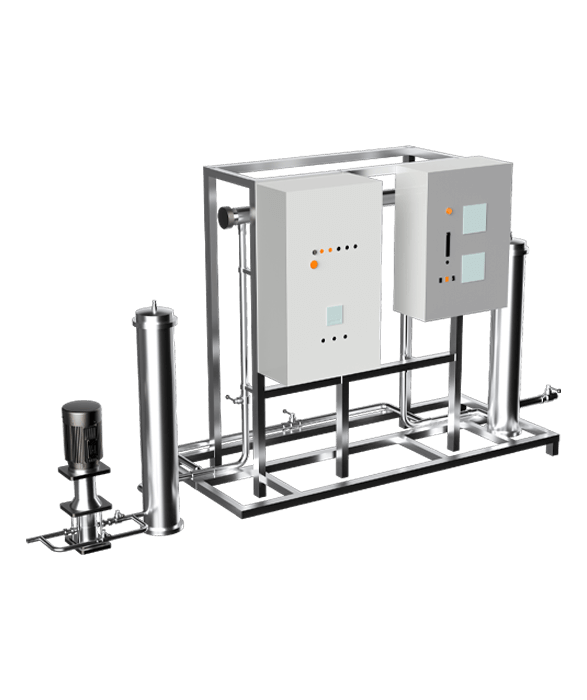

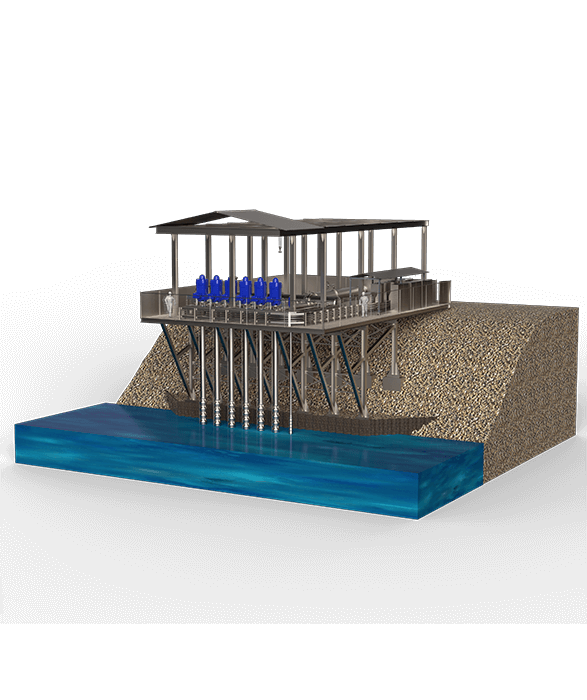

Water Processing

We work with our customers to ensure consistent and reliable pump operation with a dependable supply of custom materials.

FEATURED PRODUCTS

none

316L Project 70®+

An improved-machining version of conventional 316/316L shown to minimize carbide precipitation during welding

none

Custom 630 (17Cr-4Ni) Project 70®+

Martensitic precipitation, age-hardenable stainless alloy offering high strength and hardness, excellent corrosion resistance, and good fabricating characteristics for consistency

Turn to Carpenter Technology for consistency.

From our technical expertise and customer service to the reliable performance of our materials, we partner with companies prepared to solve challenges with our broad portfolio of engineered solutions. Our materials are recognized throughout the industry for their quality; our 316L-SCQ set the industry standard for ultra-high purity requirements.

Related Resources

Browse our growing library of resources for the market including case studies, product brochures, technical data sheets, product selection guides, and more.