INDUSTRY STANDARD?

HOW ABOUT INDUSTRY

EXCELLENCE.

Life-Changing Innovation

What we do changes people's lives. Biomedical implants and surgical instruments must meet extremely stringent composition, fabrication, and functional standards.

We work closely with the medical industry to develop and apply new products and processes that transform what the medical world and patients are able to achieve.

APPLICATION SPOTLIGHT

Medical

Orthopedic Joint Reconstruction

Orthopedic implants require not only biocompatibility, but also exceptional mechanical properties and corrosion resistance in intense physiological conditions over a long service life, requiring materials with exceptionally high abrasion (wear) and fatigue resistance.

FEATURED PRODUCTS

Biodur® CCM / Biodur® Cold Work CCM

Enhanced strength and wear resistance can be achieved by incorporating cold work in the material. Small diameter offerings available

none

Micro-Melt® Biodur® CCM Plus

Retains higher strength and exceptional wear resistance irrespective of manufacturing method driving consistent performance over lifetime

none

Micro-Melt® Biodur® CCM

Increased processability due to finer grain sizes and superior homogeneous composition available in small diameter offerings to improve processing yields

none

Dynamet Ti 6Al-4V ELI

Titanium offers increased corrosion resistance and a high strength-to-weight ratio. Available in four commercially pure grades

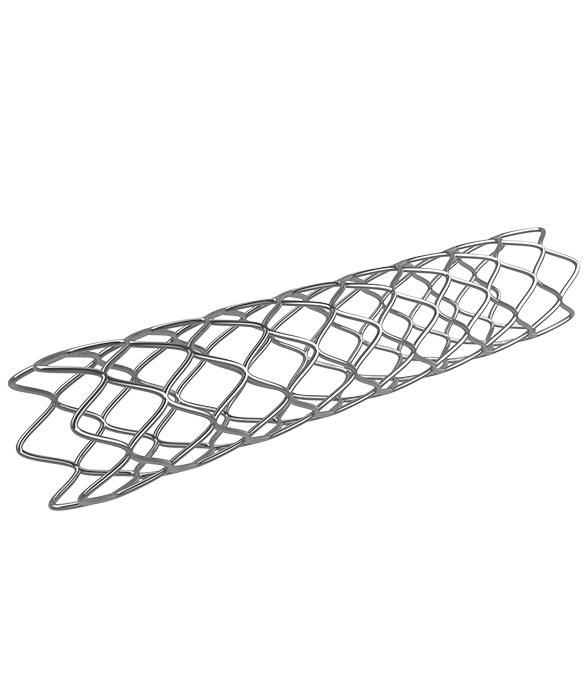

Cardiovascular Stents

Our materials enable expandable stents with high elastic modulus, low recoil, thinner struts through strong tensile properties. Reducing strut thickness improves clinical performance and reduces stent size, enabling access to smaller vessels.

FEATURED PRODUCTS

MP35N®

Nonmagnetic with a unique combination of ultra-high tensile strength, good ductility and toughness, with excellent corrosion resistance

L-605

Nonmagnetic solid-solution strengthened cobalt base alloy with oxidation-corrosion, good ductility, and toughness

Conichrome®

Stability under high fatigue requirements and good ductility with a combination of strength and corrosion resistance. Non ferromagnetic, and MRI safe

Dental Abutments and Screws

High-strength biocompatible materials resistant to corrosion and fracturing are essential for high-quality crowns, dental implants, and surgical instrumentation. Our materials have the necessary strength and low-nickel content for patients with metal sensitivities.

FEATURED PRODUCTS

Biodur® 108

FDA-approved essentially nickel and cobalt free austenitic stainless with exceptionally high tensile and fatigue strength

Micro-Melt® Biodur® CCM Low Nickel

Low nickel version retains higher strength and exceptional wear resistance irrespective of manufacturing method driving consistent performance over lifetime

Ti CP Grade 1-4

Titanium offers increased corrosion resistance and a high strength-to-weight ratio. Available in four commercially pure grades

none

Ti 6Al-4V ELI

Extra-low interstitial ASTM B348 Grade 23 has superior damage tolerance and better mechanical properties at cryogenic temperatures

Surgical Clips and Suture Wires

Our material solutions are used for the next generation of implantable surgical clips where elevated properties are required surgical clips and suture wire.

FEATURED PRODUCTS

none

Conichrome®

Stability under high fatigue requirements and good ductility with a combination of strength and corrosion resistance

none

Biodur® 316LS

High-strength, vacuum arc remelted, low carbon, high nickel and molybdenum alloy with chemistry modifications designed to maximize corrosion resistance

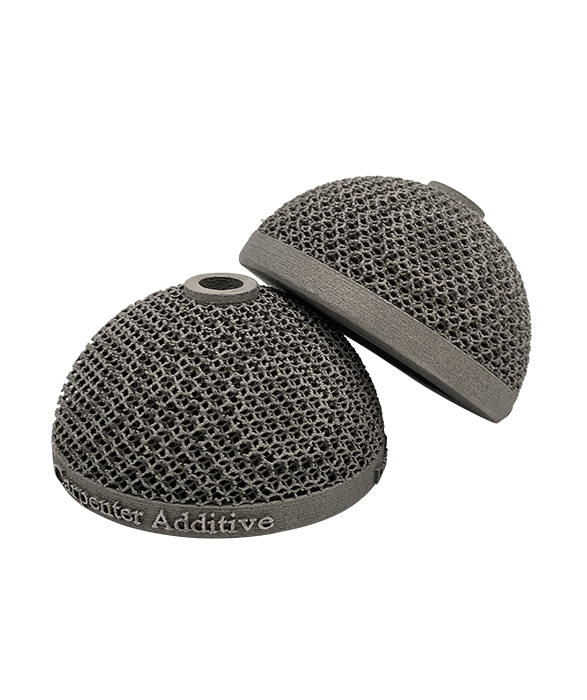

Medical Contract Manufacturing

Partner with us for end-to-end production of components, patient-matched implants, or application-specific tools created with additive manufacturing in our production facilities with powder lifecycle management and risk mitigation.

FEATURED PRODUCTS

none

Ti 6Al-4V ELI Grade 23+

Ti64 Grade 23+ combines controlled powder chemistry with lower oxygen content and optimized print parameters to provide 15-20% improvement in mechanical properties

none

Nitinol

NiTi alloys with optimized powder chemistry and print parameters exhibit superelastic and shape memory properties

none

Biodur® 108

An essentially nickel-free austenitic stainless alloy with a high nitrogen content to maintain its austenitic structure with superior tensile and fatigue strength

When stakes are high, work with us. The alternative can be costly.

Customers call on us when they need to rethink the boundaries of specialty alloys or how our existing top-performance materials can solve new design challenges. We foster long-term relationships to support risk-averse innovation and explore advanced product applications together.

Related Resources

Browse our growing library of resources for the medical market including case studies, product brochures, technical data sheets, product selection guides and more.