medical

Instrumentation & Surgical Tools

Less Invasive Procedures Enable Better Patient Recovery

The future of medical procedures is driven in part by the development of less invasive techniques that allow patients to recover faster. We help make these techniques possible. Our products and knowledge have helped us team with the medical profession to develop smaller, stronger tools and devices. These allow new and better techniques for surgeons, helping them achieve outcomes that would have been impossible a short time ago.

APPLICATION SPOTLIGHT

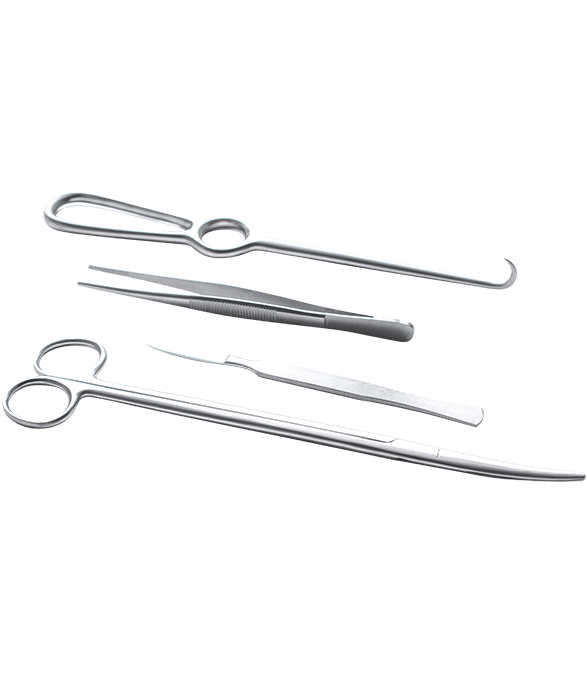

Instrumentation & Surgical Tools

Surgical Clips and Suture Wires

Our material solutions are used for the next generation of implantable surgical clips where elevated properties are required surgical clips and suture wire.

FEATURED PRODUCTS

none

Conichrome®

Stability under high fatigue requirements and good ductility with a combination of strength and corrosion resistance

none

Biodur® 316LS

High-strength, vacuum arc remelted, low carbon, high nickel and molybdenum alloy with chemistry modifications designed to maximize corrosion resistance

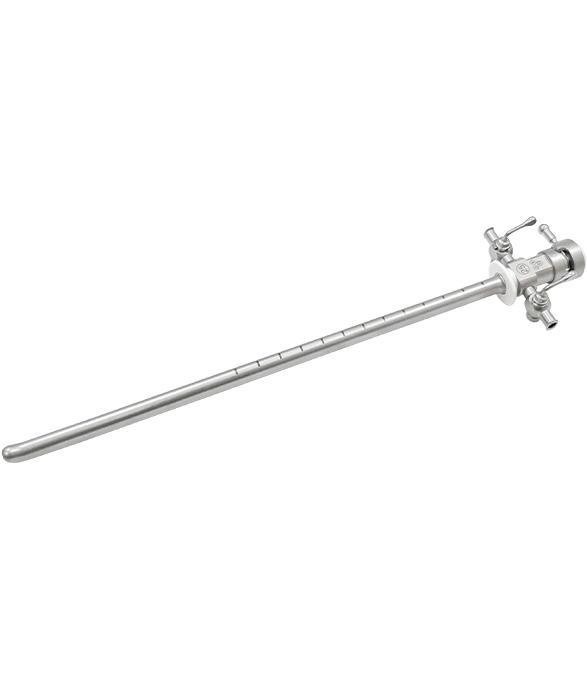

Endoscopy and Arthroscopy

Seamless tubing with increased strength allows for thinner wall structures enabling surgeons to perform minimally invasive surgeries that reduce patient damage and improve healing times.

FEATURED PRODUCTS

none

Custom 465®

Best-in-class high-strength stainless steel with good edge retention and corrosion resistance

none

Custom 630 (17-4)

Martensitic precipitation, age-hardenable stainless alloy offering high strength and hardness, excellent corrosion resistance, and good fabricating characteristics

Surgical Instruments and Staples

Our broad portfolio of materials offer a range of solutions for surgical staples and instrumentation, including titanium optimized for manufacturing and high-strength stainless alloys that enable reduced instrument size and tighter radii.

FEATURED PRODUCTS

none

Dynamet Ti CP Grade 1-4

Titanium offers increased corrosion resistance and a high strength-to-weight ratio. Available in four commercially pure grades to optimize performance

none

Custom 465®

Best-in-class high-strength stainless steel designed for improved notch tensile strength, fracture toughness already commonly used in screwdrivers and nut drivers

none

Custom 630 (17Cr-4Ni)

Martensitic precipitation, age-hardenable stainless alloy offering high strength and hardness, excellent corrosion resistance, and good fabricating characteristics

Work with Carpenter Technology to improve your product and your process.

We provide a diverse portfolio of solutions for device design and implantation, enabling the development of advanced components with increased strength, wear, and tolerance.

Our long history of custom application engineering combined with our product knowledge have resulted in a wide array of accessible innovations and available products.

Related Resources

Browse our growing library of resources for the market including case studies, product brochures, technical data sheets, product selection guides, and more.