medical

Manufactured Parts

End-to-End Expertise in Advanced Additive Contract Manufacturing for Medical Devices

We ensure top-quality additively manufactured components so you can focus on improving patient outcomes. Let our experts guide your additive journey. Partner with us for production components, patient-matched implants, or application-specific tools created with additive manufacturing in our production facilities with powder lifecycle management and risk mitigation. We have expertise in end-to-end additive manufacturing of parts. Or we can consult with you at any stage in the process, adding value to your current additive manufacturing processes.

APPLICATION SPOTLIGHT

Contract Manufacturing

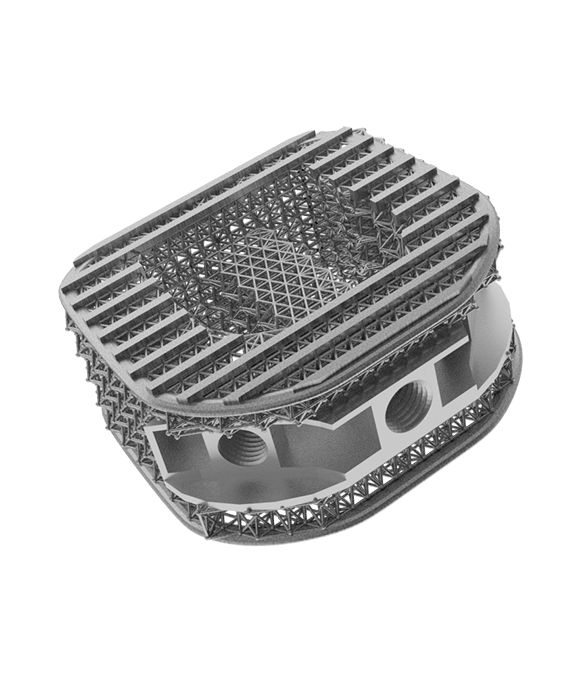

Laser Powder Bed Fusion

Our process allows for the creation of fine details and complex geometries in full-scale production. Medical device manufacturers turn to our materials and process expertise to successfully print their most stringent next-generation implant designs.

FEATURED PRODUCTS

none

Ti 6Al-4V ELI Grade 23+

Ti64 Grade 23+ combines controlled powder chemistry with lower oxygen content and optimized print parameters to provide 15-20% improvement in mechanical properties

none

Nitinol

NiTi alloys with optimized powder chemistry and print parameters exhibit superelastic and shape memory properties

none

Biodur® 108

An essentially nickel-free austenitic stainless alloy with a high nitrogen content to maintain its austenitic structure with superior tensile and fatigue strength

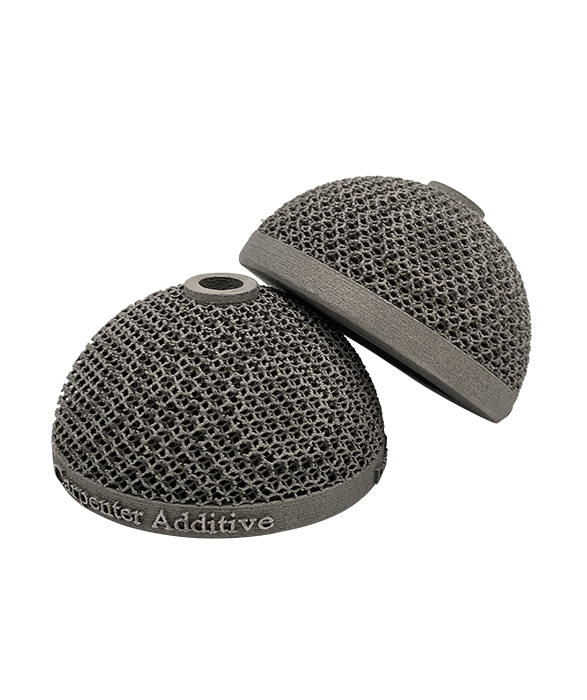

Electron Beam Powder Bed Fusion

We are a trusted partner for medical device manufacturers, assisting in production to successfully print the most complex implant designs that typically fail using standard grade materials.

FEATURED PRODUCTS

none

Ti 6Al-4V ELI Grade 23+

Ti64 Grade 23+ combines controlled powder chemistry with lower oxygen content and optimized print parameters to provide 15-20% improvement in mechanical properties

none

Ti 6Al-4V ELI Grade 23

An extra-low interstitial version offering biocompatibility, good fatigue strength, and low modulus with superior damage tolerance and mechanical properties at cryogenic temperatures

Work with Carpenter Technology to improve your product and your process.

Carpenter Additive is a fully integrated metal additive manufacturing (AM) partner, working with you throughout your additive production. Success with industrial metal 3D printing requires material expertise and we have over a century of experience precisely engineering and controlling material properties and are at the forefront of scaling AM to qualified production in critical industries such as medical devices.

Our team of experts partners with customers from concept to creation to ensure success and add value throughout the AM process. We offer standard and custom powders, material handling strategies, and full contract manufacturing services with a variety of production additive systems.

Related Resources

Browse our growing library of resources for the market including case studies, product brochures, technical data sheets, product selection guides, and more.