Highest purity for peak performance

Carpenter Technology specializes in high-purity alloys designed to perform in corrosive environments with no tolerance for contamination. We are the trusted partner in ultra-high purity gas delivery applications.

40+ years

experience in the semiconductor industry

Key supplier

to major fluid control, metrology, motion system, and shielding device manufacturers

World’s largest

Vacuum Induction Melting (VIM) capacity

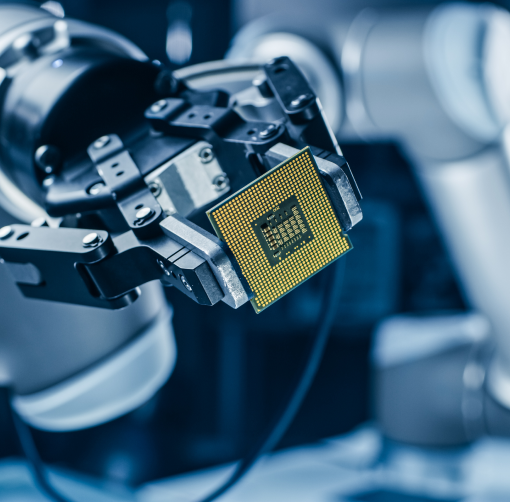

Advanced alloys for semicon production

Our semiconductor alloys are engineered to meet unique application requirements in corrosion resistance, cleanliness, weldability, machinability, and electro-polishability. Our in-house metallurgical and manufacturing expertise gives you the competitive edge.

Industry vanguard

Primary producer of high-purity 316L-SCQ, meeting tight specifications and SEMI-F20 standards.

High capacity

The largest high-purity alloy capacity.

Unmatched quality

Lab-tested and field-proven, our solutions set the standard for industry quality, ensuring component integrity in the most challenging environments.

Custom solutions

Have a unique use case or cutting-edge design? We’ll partner with you to develop a custom alloy that meets your specific needs.

Carpenter Technology brings 135 years of metallurgical innovation to semiconductors, pushing the limits of what’s possible, solving evolving design challenges, and partnering with industry leaders to build high-value integrated circuits.

EXPLORE THE POSSIBILITIESAPPLICATION SPOTLIGHT

SEMICONDUCTORS

Gas delivery systems

Corrosion resistance, cleanliness, weldability, and electro-polishability for critical components — valves, fittings, regulators, and filters — designed for the rigorous demands of deposition, etching, and general fabrication construction.

FEATURED PRODUCTS

none

ULTRA-HIGH PURITY (UHP)

Optimized for strength, corrosion resistance, high pitting resistance, and elevated material cleanliness in demanding environments

none

HIGH PURITY (HP)

The benchmark for reliability in fluid delivery applications

none

SPECIALIZED ALLOYS

Materials for bespoke application needs, including Conichrome®/Elgiloy® (Co-Cr-Ni-Mo), C-276, and 625

Measurement systems

Uniformity and thermal, temporal stability for critical components that uphold the integrity of measurement systems, including precision-crafted sensors and mounts.

FEATURED PRODUCTS

none

ULTRA-HIGH PURITY (UHP), 13-8 MO

For applications demanding both uniformity and precision

none

INVAR 36

Known for its remarkable thermal stability

none

SUPER INVAR 32-5

Unparalleled temporal stability in measurement systems

Motion systems

Specialized components for linear actuation and galling-prone applications. Alloys designed to combat galling and enhance wear resistance to ensure consistent, reliable motion in semiconductor machinery.

FEATURED PRODUCTS

none

GALL-TOUGH® / NITRONIC® FAMILY

Specifically engineered for galling and wear resistance

none

440C

A high-grade stainless steel for high-stress applications

Shielding

Alloys for advanced flux concentrators and shielding solutions that facilitate superior control over magnetic induction and deliver high performance.

FEATURED PRODUCTS

none

HIGH PERMEABILITY 49

Tailored for high permeability in magnetic fields

none

HYMU 80

Exceptional shielding capabilities

316L-SCQ: The pinnacle of surface excellence

Carpenter Technology produces three standard and multiple custom variants of 316L-SCQ, an austenitic stainless steel with:

Best-in-class surface finish

Customizable sulfur content

Micro-cleanness

Melting matters

In-house premium melting processes give us precise control over the chemistry, cleanliness, performance, and quality of our alloys:

Air melting + vacuum arc remelting (AOD+VAR)

Vacuum induction melting + vacuum arc remelting (VIM+VAR)

Amplify your next-gen semiconductor components

Find out how Carpenter Technology’s high-purity alloys can revolutionize your applications.

Elgiloy® is a registered trademark of Combined Metals Company. Nitronic® is a registered trademark of Cleveland Cliffs Steel Corporation.