We're your best partner for building a better future.

SUSTAINABLE SOLUTIONS FOR GLOBAL IMPACT

Environmental Stewardship

MINIMIZING OUR ENVIRONMENTAL IMPACT

Carpenter Technology is committed to protecting the environment and minimizing our impact through a managed sustainability program. You can learn about our environmental sustainability program through our public disclosures, including our annual Sustainability Reports, our Sustainability Accounting Standards Board (SASB) report, and our Task Force on Climate-related Financial Disclosures (TCFD) report.

GOVERNANCE AND POLICIES

The Environmental, Health, and Safety (EHS) team at Carpenter Technology oversees our environmental management system with technical experts in all facilities where we operate. The EHS team develops policies and protocols that establish our global standards for energy management and greenhouse gas emissions, air emissions, waste, water, scrap metal recycling, sustainable sourcing, safety standards, and training. In addition, the EHS team is responsible for ensuring we are compliant with applicable legal and regulatory requirements while aligning with best practices.

ENVIRONMENTAL MANAGEMENT SYSTEM

The majority of Carpenter Technology’s manufacturing facilities are ISO14001 certified. These facilities generate over 90% of our business.

RISK IDENTIFICATION AND MANAGEMENT

We identified a set of transition risks associated with the shift to a low-carbon and climate-resilient economy, including: carbon pricing relevant to facilities and products, mandates and regulations on existing products and services, and shifts in consumer preferences. We also recognize that extreme weather events pose a physical risk to our supply chain that could impact our operations.

We also see opportunities in the transition to a low-carbon economy: additional growth through new sustainable products and markets, and improved operational performance through increased efficiency of our operations. We believe we are well-positioned to take advantage of the opportunities as detailed in the Sustainable Solutions section.

GOALS TO MINIMIZE OUR ENVIRONMENTAL IMPACT:

We continuously track progress and seek opportunities for more goal setting activities to further minimize our impact.

-

Reduce GHG emissions intensity

-

Reduce energy intensity

-

Reduce fresh water intensity

-

Reduce and recycle waste

-

Reduce air pollution emissions

-

Source materials sustainably

ENERGY MANAGEMENT

Metal manufacturing is an energy-intensive process, primarily using electricity and natural gas to melt and process metal alloys. Carpenter Technology actively monitors and manages energy consumption across all operating locations. Our goal is to maximize energy efficiency to reduce costs and minimize our impact on the environment. This is primarily achieved by minimizing manufacturing waste and material reprocessing.

We aim to achieve this by investing in new, more efficient technologies for furnace operations, lighting, and HVAC systems. In 2023, our energy intensity was 83 GJ per metric ton of material produced, an improvement from 2022 (85 GJ per metric ton) due to increased productivity in our plants and energy-saving programs like the LED replacement program at our Reading, PA facility.

LED REPLACEMENT PROGRAM

Our manufacturing facilities are replacing traditional HID light systems with LED fixtures. In some instances, energy usage has been reduced to 1/3 of original energy consumption and has improved safety through increased lighting levels while also minimizing the maintenance burden typically required with traditional lighting systems.

WATER MANAGEMENT

Water use and management is an important component of our manufacturing process, as water is used to cool material at specified rates.

We look to implement best practices in water use. One recent example of water consumption and discharge reduction was the implementation of a water recirculation system, allowing our Reading facility to reuse and recycle more than 90% of water used in production. Looking ahead, we plan to introduce and expand the following activities to our other facilities:

- Install leak detection and monitoring equipment to reduce waste.

- Utilize local high-rate water recycling and reuse systems to minimize the amount of water required for cooling.

Water Use in 2023

We manage wastewater discharge in accordance with the National Pollutant Discharge Elimination System Permits implemented by the U.S. Environmental Protection Agency (EPA). All sites conduct routine monitoring of treated wastewaters and stormwaters through sampling and analysis to ensure compliance with respective permits and limits.

By preventing waste in our manufacturing processes, we can reduce environmental risk and operational costs. We track the amounts and types of waste generated by each facility and review audits of our third-party waste management partners.

In addition to waste reduction, we reuse, recycle, or recirculate as many byproducts as possible. In 2023:

- 75% of feedstock used in production is recycled scrap

- We recycle 100% of slag produced in our melt operations

Our waste management approach ensures that all waste, including hazardous and nonhazardous waste, is disposed of in compliance with national and international waste management requirements, including the EPA's Resource Conservation and Recovery Act (RCRA) and the EU’s Restriction of Hazardous Substances Directive (RoHS). We dispose of waste at approved Treatment, Storage, or Disposal Facilities (TSDFs) that have obtained proper environmental permits for disposal. Also, we encourage recycling office waste, including e-waste which is handled by our IT department to ensure it is done properly.

We had zero reportable spills in 2023. At our facilities, we train our employees on emergency procedures and how to respond in the event of a spill.

AIR EMISSIONS

We closely monitor and report air emissions from our major manufacturing sites. All air emissions data can be found in our latest SASB table.

All manufacturing facilities strictly comply with applicable regulatory requirements regarding emissions limits and hold valid air permits. We have implemented measures to reduce emissions, including dust, mist, and fume pollution capture and control systems, and efficiency is always a consideration during equipment repair and upgrades.

BIODIVERSITY

Carpenter Technology does not operate in areas of high biodiversity risk or in areas with critical habitats, as identified and defined by scientific and conservation organizations such as IUCN and UNEP-WCMC. In addition, the company does not engage in activity associated with land disturbance or tailing ponds. Because our operations do not pose a significant risk to biodiversity, the topic does not reach the threshold of materiality in comparison to other operational areas.

Nonetheless, Carpenter Technology manages biodiversity responsibly and in accordance with applicable laws and regulations and will continue to assess and monitor the impact of our operations on biodiversity. We continue to manage areas within our sustainability program that overlap with considerations in biodiversity such as greenhouse gas emission reduction activities, air emission management, and water management.

SUSTAINABLE SOURCING AND SUPPLY CHAIN MANAGEMENT

We are committed to conducting our business in an ethical, legal, and socially responsible manner. We expect our suppliers, customers, and vendors around the world to operate in line with the values outlined in our Code of Business Conduct and Ethics, Human Rights Policy, and Supplier Code of Conduct.

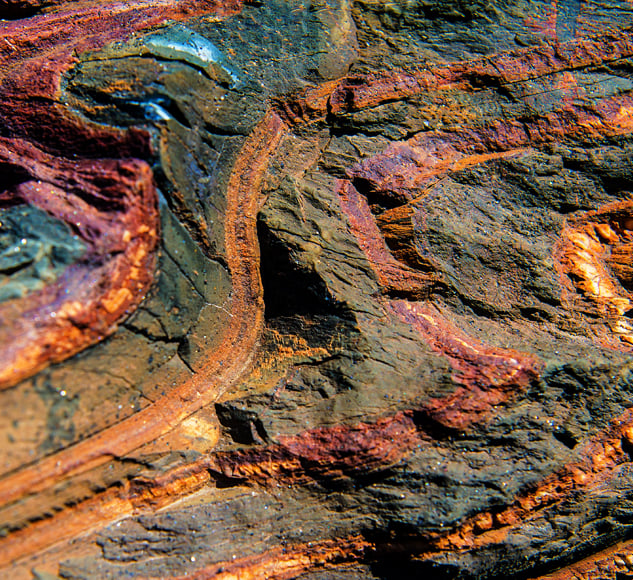

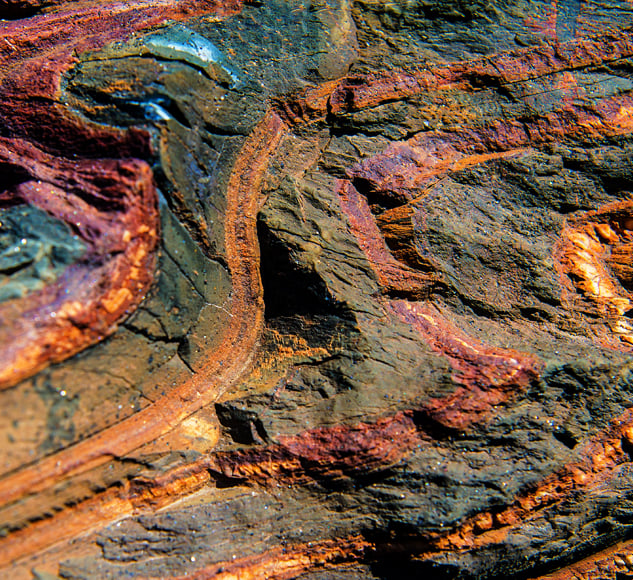

Sustainable Sourcing

Carpenter Technology is proud to create products that contain as much recycled or reclaimed material as possible. We rely heavily on the use of reclaimed metal in our production of highly specialized metal alloys to reduce the need to procure carbon-intensive inputs:

- We recover as much metal byproduct as possible from our operations.

- We seek opportunities to source scrap material from customers to return to our production process.

We are committed to finding more ways to incorporate recycled scrap into our operations based on applicable environmental regulations and best management practices while regularly working with our customers to recycle scrap materials.

We also source materials from suppliers that align with our sustainability mission to reduce environmental impact through carbon-neutral programs, including our main source of pure nickel.

In 2023, we launched our Sustainable Supplier program. We are working with our suppliers to better understand their primary sources of emissions and ways that we can work together to reduce environmental impact.

CONFLICT MINERALS

We ensure materials used in our products are sourced in an ethical manner and in compliance with applicable laws and regulations, including the Security Exchange Commission's "Conflict Minerals" rules. In accordance with these rules, we do not purchase minerals that originate from the Democratic Republic of the Congo or any other region that is not certified conflict-free.

RESPONSIBLE MINERALS INITIATIVE

To remain at the forefront of sustainable sourcing practices, we work with the Responsible Minerals Initiative (RMI) to assess and validate conflict-free

suppliers, on environmental sustainability and human rights.

RMI provides the following tools and resources to ensure our business remains compliant and in support of sustainable mineral supply chains:

- Supply chain mapping using reporting templates.

- Third-party assessments of smelters, refiners, and downstream companies.

- RMI eLearning Academy to provide training to supply chain professionals.

- Risk assessments to identify high-risk areas in mineral supply chains.

- Reporting mechanisms to communicate due diligence programs.

To further our understanding of best practice in terms of conflict mineral management, Carpenter Technology is an active member in the RMI Alliance Program. This program allows companies to collaborate on best practice as it relates to conflict mineral management, due diligence, and supplier sustainability.