Transportation

Medium & Heavy Duty Vehicles & Off-Road Equipment

Materials Engineered for Durability in the Most Challenging Operating Conditions

We have been a global, trusted partner driving improvements in durability and performance in the medium duty, heavy duty, and off-road vehicle market segments since they were invented. Our advances in material technology have allowed our customers to design to higher temperatures and pressures, extend service intervals, and operate in a variety of corrosive environments.

APPLICATION SPOTLIGHT

Medium & Heavy Duty Vehicles and Off-Road Equipment

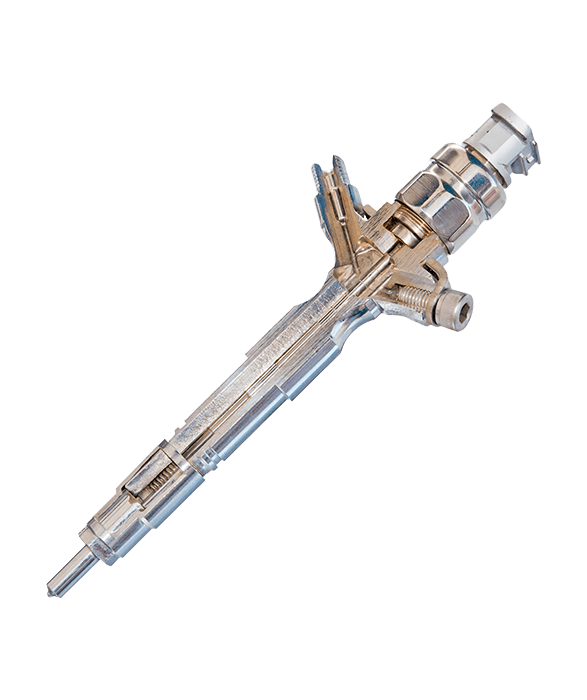

Diesel Fuel Injectors

Ultra-clean materials enable the highest pressure diesel applications. Our materials allow higher pressure and temperature resistance while increasing fatigue life.

FEATURED PRODUCTS

none

M2

High-speed steel with a balance of wear resistance and cost-effectiveness that machines more easily than conventional options

none

H13

5% chromium hot-work tool steel combining a high-level toughness, thermal fatigue, and hot hardness properties

none

Spring Steel

Ultra-low inclusion steel for high cycle fatigue applications

none

Hiperco® 50A

Highest magnetic saturation with low coercivity and the lowest losses. Combines magnetic permeability with superior strength

Diesel Exhaust Valves

We are high temperature materials experts with a full portfolio of materials that perform in the harsh environment combination of dry fuels, oxidative environments, and temperatures in excess of 800° C.

FEATURED PRODUCTS

none

G27

Cobalt-free alloy with excellent high-temperature performance, improved oxidation resistance, and a wide hot-working range

none

31V

Sulfidation-resistant, precipitation-hardenable superalloy with an unusual combination of corrosion resistance and strength to 1500°F (816°C)

none

751

High-strength, nickel-base alloy obtaining maximum high-temperature properties through age-hardening with good fatigue behavior up to 1600°F (862°C)

none

80A

Nickel-base alloy having excellent creep- and oxidation-resistant properties and high resistance to fatigue with acceptable drillability for critical applications

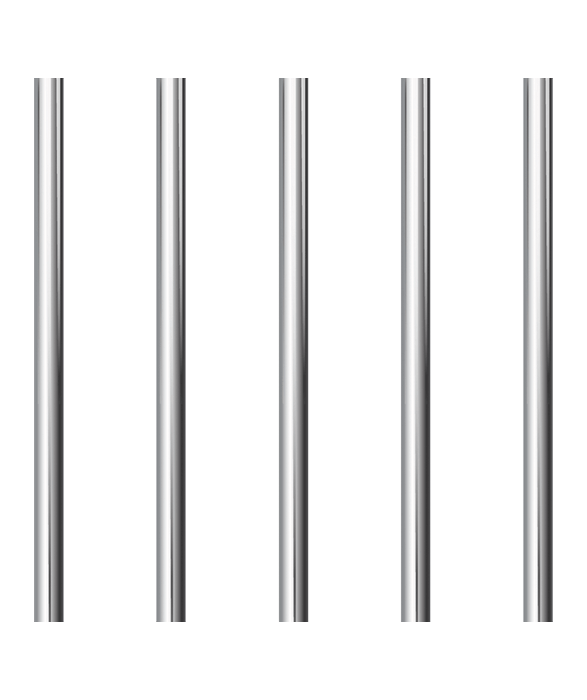

Pushrod End/Rollers

Pushrod ends operate in harsh wear environments and non-optimal oil film environments. Our HIP’d tool steels offer superior wear resistance, enhanced fabricating characteristics, and better toughness than traditional tool steels.

FEATURED PRODUCTS

none

Micro-Melt® M4

High-speed tool steel with elevated carbon and vanadium content providing very high wear resistance and strength with enhanced performance

none

Micro-Melt® 440C

A stainless through-hardening steel, with uniform distribution of fine carbides when HIP’d

none

Micro-Melt® A11

High-vanadium cold work tool steel with wear resistance superior to most other cold work steels, good strength, and toughness characteristics

none

Micro-Melt® Maxamet®

High speed steel with excellent wear resistance due to a high carbide volume, and good toughness at high hardness levels

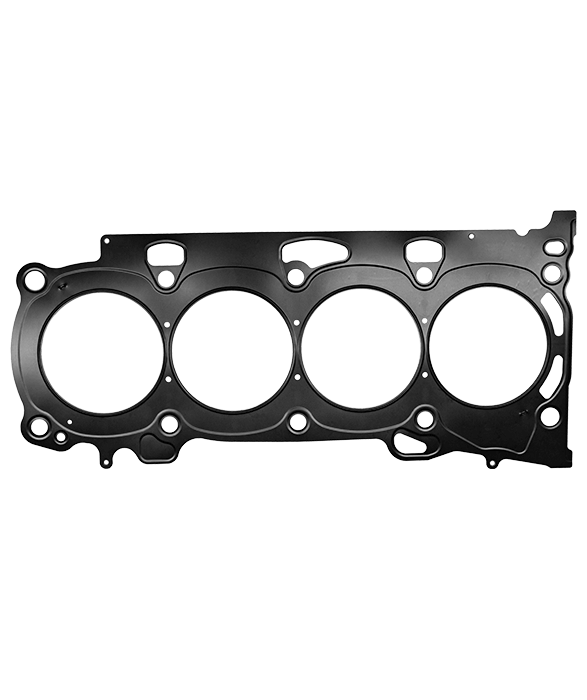

High Temperature Gaskets

Carpenter’s wide range of strip thickness and alloy capabilities will allow you to customize your gasket design to meet your sealing and temperature needs.

FEATURED PRODUCTS

none

718

Nickel-base alloy that offers exceptionally high yield, tensile and creep-rupture properties in a weldable material with corrosion resistance

none

Waspaloy

Precipitation-hardening, nickel-base alloy with good strength and corrosion resistance, high creep resistance and grades for elevated temperature tensile strength

none

625

Solid-solution-strengthened nickel-base alloy with strength and toughness, excellent fatigue strength, and stress-corrosion cracking resistance to chloride ions

none

G27

Cobalt-free alloy with excellent high-temperature performance, improved oxidation resistance, and a wide hot-working range

Work with Carpenter Technology to improve your product and your process.

We continue to innovate for the medium and heavy duty markets. Our team of material experts developed our latest patented alloy, G27, to increase performance and durability. Our products have consistent global quality and part design costs while meeting the exacting design requirements of the higher operating temperature of today's internal combustion engines.

EXPERT ADVICE WHEN YOU NEED IT

Customers call on us when they need to rethink the boundaries of specialty alloys

Related Resources

Browse our growing library of resources for the market including case studies, product brochures, technical data sheets, product selection guides, and more.