Transportation

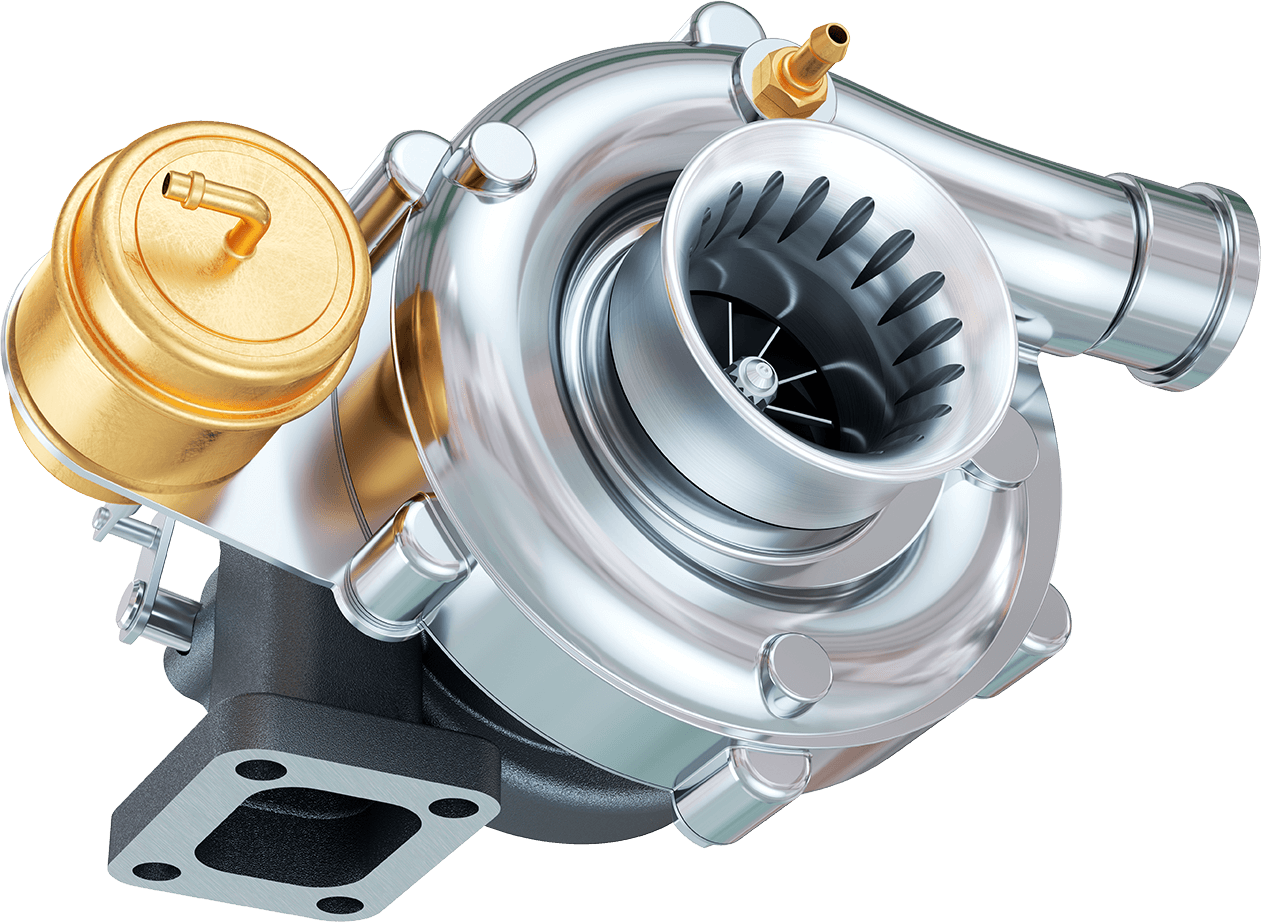

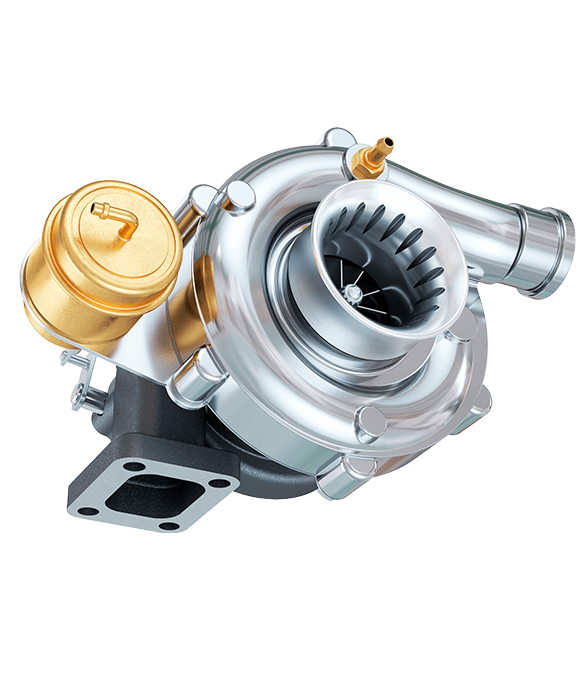

Turbocharger

Material Innovations for Advanced Combustion

Whether your customers demand higher performance or compliance with environmental regulations, the modern turbocharger faces increasing performance demands. We are your trusted partner for engineered solutions in harsh environments with increasing temperature, corrosion, and wear driven operating conditions.

APPLICATION SPOTLIGHT

Turbocharger

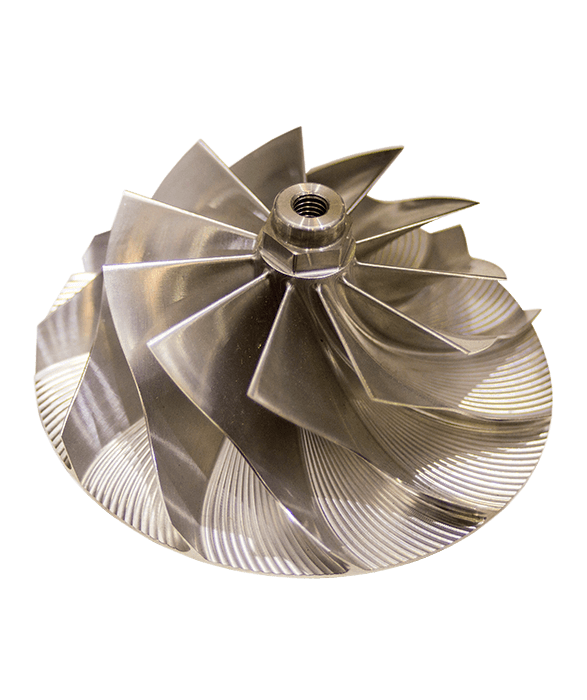

Turbine Wheel

We offer next-generation powder metallurgy to drive the needs of increasing temperatures in modern turbocharged engines.

FEATURED PRODUCTS

none

718

Precipitation-hardened, nickel-base alloy that offers exceptionally high yield, tensile and creep-rupture properties up to 1300°F (704°C)

none

Ti 6Al-4V

A fully heat treatable workhorse alloy performing at temperatures up to 650°F (350°C) offering strength with light weight and corrosion resistance

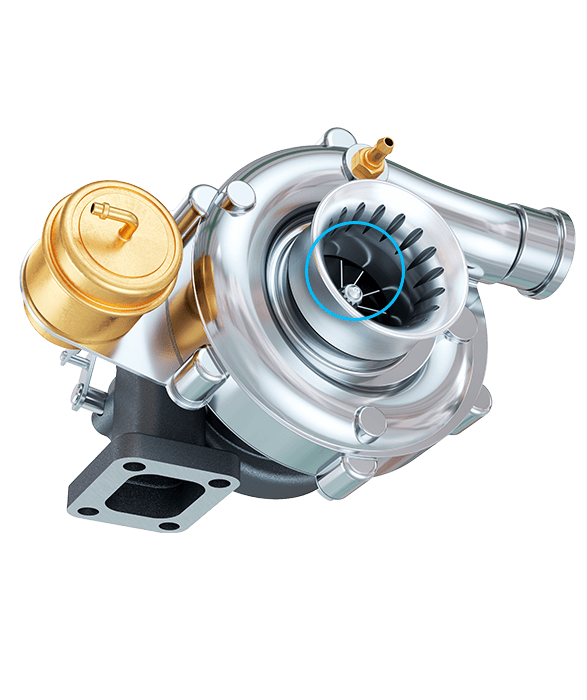

Bearing

We deliver a full suite of durable, wear-resistant solutions for the needs of current and next-generation turbochargers.

FEATURED PRODUCTS

none

440C

Stainless capable of attaining very high hardness, approximately Rockwell C 60

none

M-50

High carbon steel with good wear resistance and fatigue performance

none

M2

High-speed steel with a balance of wear resistance and cost-effectiveness that machines more easily than conventional options

Shaft

We offer a full range of temperature-resistant materials for today's high performing shafts.

FEATURED PRODUCTS

none

80A

Nickel-base alloy having excellent creep- and oxidation-resistant properties and high resistance to fatigue with acceptable drillability for critical applications

none

NCF 3015 (30Ni)

Precipitation-hardenable, iron-nickel base alloy designed for high strength and corrosion resistance up to 1400°F (760°C)

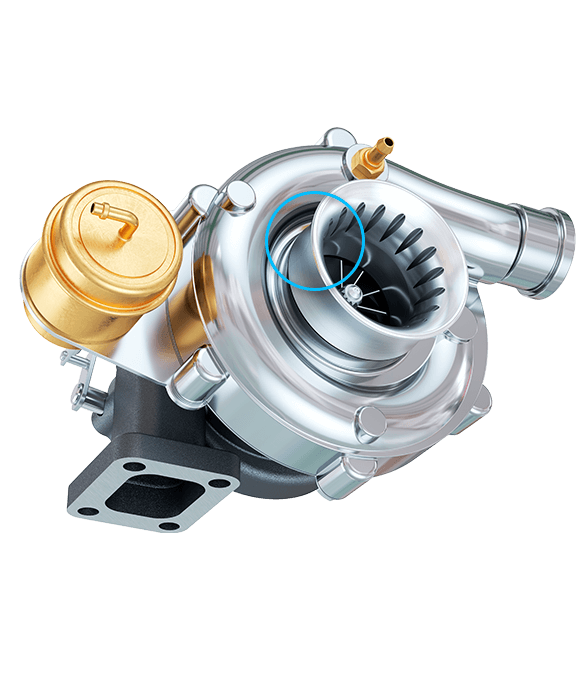

Vanes

We offer next-generation powder metallurgy with exceptional high-temperature performance for modern VGT designs.

FEATURED PRODUCTS

none

718

A precipitation-hardenable nickel-base alloy with exceptionally high yield, tensile, and creep-rupture properties at temperatures up to 1300°F (704°C)

Unison Ring

Our alloy solutions offer exceptional high-temperature performance for modern VGT designs.

FEATURED PRODUCTS

none

718

Precipitation-hardened, nickel-base alloy that offers exceptionally high yield, tensile and creep-rupture properties up to 1300°F (704°C)

none

A-286

Cost-effective, iron-base austenitic stainless steel with notched rupture strength superior to any other alloy with comparable high-temperature properties

none

625

Solid-solution-strengthened nickel-base alloy with strength and toughness, excellent fatigue strength, and stress-corrosion cracking resistance to chloride ions

none

Waspaloy

Precipitation-hardening, nickel-base alloy with good strength and corrosion resistance with high creep resistance and grades for elevated temperature tensile strength

Piston Ring

Our materials provide best-in-class high-temperature sealing performance for the most demanding applications.

FEATURED PRODUCTS

none

706

Nickel-base alloy with high-strength with improved fabricability that can be processed into larger ingots and forgings than other superalloys

none

718

Precipitation-hardened, nickel-base alloy that offers exceptionally high yield, tensile and creep-rupture properties up to 1300°F (704°C)

none

Waspaloy

Precipitation-hardening, nickel-base alloy with good strength and corrosion resistance with high creep resistance and grades for elevated temperature tensile strength

none

A-286

Cost-effective, iron-base austenitic stainless steel with notched rupture strength superior to any other alloy with comparable high-temperature properties

Work with Carpenter Technology to improve your product and your process.

We create new opportunities throughout the product lifecycle: we mitigate demand risks in volatile markets and serve as a global supply partner in today’s design cycles, while simultaneously investing in next-generation materials and production techniques to meet tomorrow’s design needs. Our industry-leading breadth of alloys and product forms to support the most demanding turbocharger and manifold applications.

Related Resources

Browse our growing library of resources for the market including case studies, product brochures, technical data sheets, product selection guides, and more.