INDUSTRY STANDARD?

HOW ABOUT INDUSTRY

EXCELLENCE.

New Materials; Higher Performance

Advances in engine technology increasingly depend on new material solutions. New materials can deliver stronger performance at higher temperatures, reduce weight, and decrease fuel consumption.

From supply reliability to providing trusted advice, we are sought after by the technical community to solve problems and deliver more efficiency, reliability, and cost-effectiveness through superior material performance.

APPLICATION SPOTLIGHT

Transportation

Light Duty Engine Valves

Increasing peak cylinder temperatures and pressures require high performing, yet cost-effective alloys with excellent elevated temperature fatigue behavior. We offer a total solutions package for superior heat and wear resistance.

FEATURED PRODUCTS

none

21-2N

Good mechanical properties and wear resistance at lower operating temperatures

none

NCF 3015 (30Ni)

Precipitation-hardenable, iron-nickel base alloy designed for high strength and corrosion resistance up to 1400°F (760°C), yet still drillable

none

80A

Nickel-base alloy having excellent creep- and oxidation-resistant properties and high resistance to fatigue with acceptable drillability for critical applications

none

Iron, Nickel, Cobalt PTA Powders

Offering a range of PTA powders ranging from Fe-based alloys up to Co-based alloys. Custom blends available

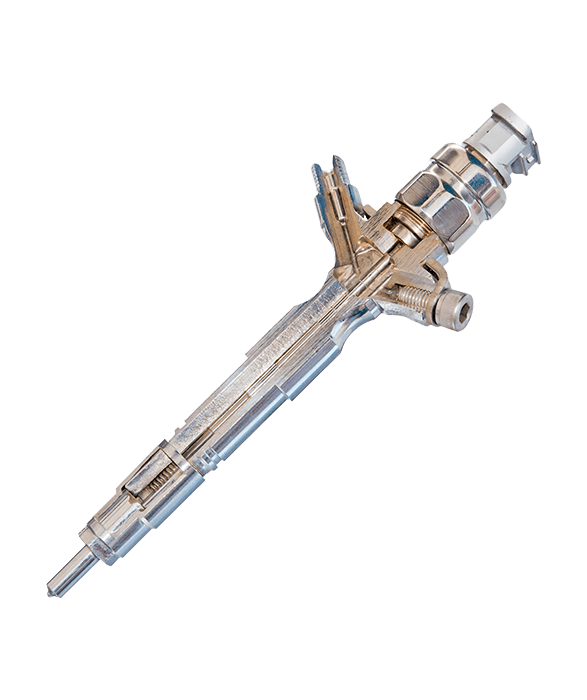

Diesel Fuel Injectors

Ultra-clean materials enable the highest pressure diesel applications. Our materials allow higher pressure and temperature resistance while increasing fatigue life.

FEATURED PRODUCTS

none

M2

High-speed steel with a balance of wear resistance and cost-effectiveness that machines more easily than conventional options

none

H13

5% chromium hot-work tool steel combining a high-level toughness, thermal fatigue, and hot hardness properties

none

Spring Steel

Ultra-low inclusion steel for high cycle fatigue applications

none

Hiperco® 50A

Highest magnetic saturation with low coercivity and the lowest losses. Combines magnetic permeability with superior strength

High-Performance Fasteners

Our specialty alloys help maintain the highest of clamp loads available in wire, bar, and shaped bar geometries.

FEATURED PRODUCTS

none

Custom 465®

High-strength stainless steel with superior corrosion resistance and strength to withstand high torques in harsh environments for extended periods of time

none

625 Plus

Superior corrosion resistance with improved pitting resistance and improved hydrogen stress cracking resistance

none

A-286

Iron-base austenitic stainless steel with notched rupture strength superior to any other alloy with comparable high-temperature properties

none

MP35N®

Unique combination of ultra-high tensile strength, good ductility, and toughness, with excellent corrosion resistance

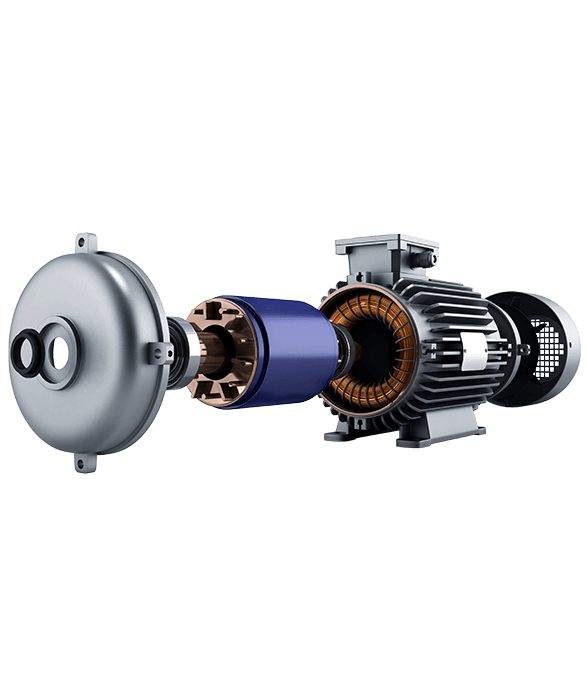

EV Traction Motors

We are the industry leader for high performance soft magnetic alloys and stator and rotor stacks for higher power, torque-dense, and highly efficient motors for improved range, acceleration, and lower powertrain costs.

FEATURED PRODUCTS

none

Hiperco® 50A

Highest magnetic saturation with low coercivity and the lowest losses with mechanical properties that can help optimize power-dense motors

none

Hiperco® 50

Highest magnetic induction and low losses with mechanical properties that can be tailored to meet both stator and rotor applications

none

Hiperco® 50HS

Highest magnetic induction and high yield strength. Tailored properties can meet demands for power dense, high speed motors

none

Hypocore

Combination of high magnetic induction and low losses for higher continuous power with low cobalt composition and low coercivity

When stakes are high, work with us. The alternative can be costly.

Customers call on us when they need to rethink the boundaries of specialty alloys or how our existing top-performance materials can solve new design challenges. We foster long-term relationships to support risk-adverse innovation and explore advanced product applications together

Related Resources

Browse our growing library of resources for the market including case studies, product brochures, technical data sheets, product selection guides and more.