INDUSTRY STANDARD?

HOW ABOUT INDUSTRY

EXCELLENCE.

It Takes Energy to Make Energy

Energy production is a demanding business that requires resilient materials... and personnel.

To make our customers more efficient and their businesses more profitable, we supply oil and gas producers, nuclear and natural gas-fired power plants, and renewable energy companies with high-quality specialty alloys. Our products are specifically designed to operate at the highest levels of performance and reliability, even in harsh, corrosive environments, high temperatures, and extreme operating stresses.

APPLICATION SPOTLIGHT

Energy

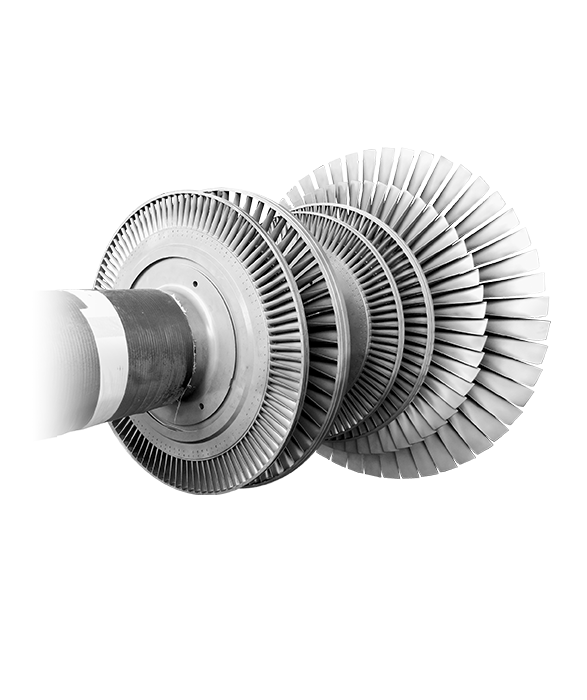

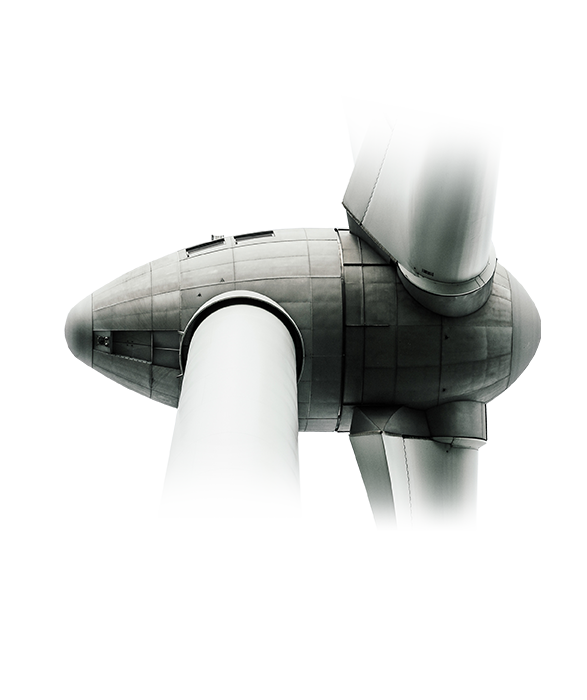

Turbine Blades and Discs

Turbine blade and disc materials are selected for their strength, fatigue life, and creep resistance in high-temperature environments. Nickel-base superalloys maximize component performance, allowing designers to achieve differentiated efficiency and reliability.

FEATURED PRODUCTS

720

High-strength, precipitation-hardening, nickel-base alloy with good oxidation and sulfide corrosion resistance and superior high temperature properties

none

Pyromet® 41

Precipitation hardening, nickel-base high temperature alloy possessing high strength in the 1200-1800°F (649-982°C) temperature range. This alloy is designed for use in severely stressed high temperature applications

none

Waspaloy

Precipitation-hardening, nickel-base alloy with good strength and corrosion resistance to 1600°F (870°C)

none

718

Precipitation hardenable nickel-based alloy designed to display exceptionally high yield, tensile, and creep-rupture properties at temperatures up to 1300°F (704°C). Excellent weldability

none

901

Chromium nickel-iron base superalloy designed for high strength and corrosion resistance in the 1000-1400°F (538-760°C) temperature range

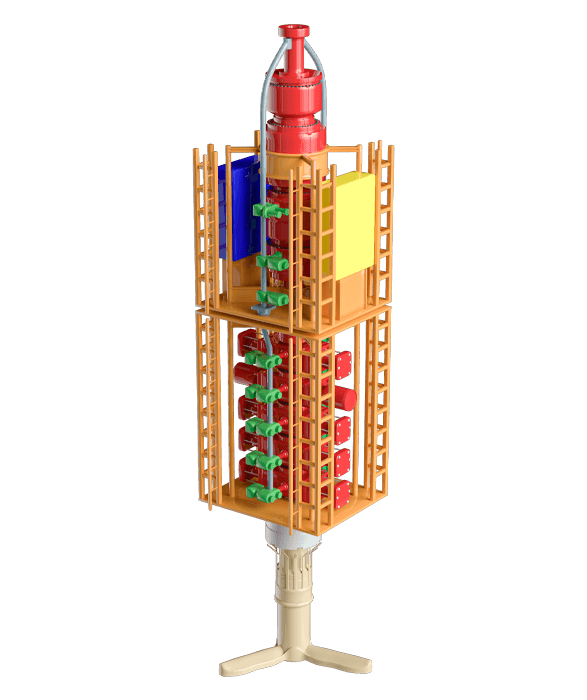

Subsea Drilling Equipment

Offshore drilling operations take place in a complex, challenging environment where failure is not an option. Every component from seafloor to surface must meet the highest standards for capability and quality. Our specialty alloys allow operators to drill with confidence and preserve their social license to operate.

FEATURED PRODUCTS

AerMet® 100

Precipitation hardenable, alloy steel with superior strength and fracture toughness. Utilized for critical components including shear ram blades for blowout preventers

MP35N®

Ultra-high tensile strength, good ductility, and toughness that is virtually immune to stress corrosion cracking and crevice corrosion in seawater

718 API 6ACRA

Nickel-base alloy that offers exceptionally high yield, tensile and creep-rupture properties with high resistance to hydrogen embrittlement

Artificial Lift

Electric submersible pumps (ESPs) are increasingly compact, with higher torque and more reliable performance. Higher power density enables rigless deployment systems to reduce workover costs in remote locations.

FEATURED PRODUCTS

Hiperco® 50

Soft magnetic alloy with high saturation and DC maximum permeability with low DC coercive force and AC core loss. Used with motor laminations to increase power density and reduce operating temperatures

718 Pump-Shaft Quality

Nickel-base alloy that offers high yield, strength, and corrosion resistance. Available in cold-worked-and-aged condition for superior strength

625

Solid-solution-strengthened nickel-base alloy with strength, toughness, and stress-corrosion cracking resistance in chloride solutions

none

Custom Age 625 Plus®

Precipitation-hardenable, nickel-base alloy with superior corrosion resistance and improved pitting and hydrogen stress cracking resistance. Available in cold-worked and aged condition for superior strength

Drill Collars

Proprietary grades of non-magnetic stainless steels specifically for directional drilling operations in corrosive and highly stressed environments. Industry-leading alloy design and processing give unsurpassed resistance to pitting, stress corrosion cracking, and fatigue life, resulting in up to a tenfold improvement in tool life.

FEATURED PRODUCTS

none

15-15LC® Modified

Nitrogen-strengthened austenitic stainless steel with low carbon content to provide improved resistance to intergranular stress-corrosion cracking with 110 ksi (758 MPa) yield strength

none

15-15HS Max

Nitrogen-strengthened austenitic stainless steel for high strength 140 ksi (966 MPa) minimum yield strength with 110 ksi (758 MPa) yield strength

none

SCF 260®

Nitrogen-strengthened austenitic stainless steel possessing 140 ksi (966 MPa) minimum yield strength and corrosion resistance in chloride environments. Field-proven performance in the North American unconventional drilling market

none

SCF 19® Max

Nitrogen-strengthened austenitic stainless steel with a combination of superior pitting and stress-corrosion-cracking resistance, high strength and fatigue life, and low magnetic permeability. Proven field performance in aggressive drilling brines and sour reservoirs

Turbine Drive Shaft

Transmitting mechanical power from the turbine blades to the generator, drive shafts are mission critical and must handle transient loads during startup, shutdown, emergency stops and grid connections.

FEATURED PRODUCTS

none

A-21®

Carburizable and nitridable stainless steel with superior corrosion resistance, fatigue life, and fracture toughness with high yield strength. Hard, corrosion resistant carburized case, ductile core

none

PremoMax®

Premium alloy steel with a combination of high strength, excellent impact and fracture toughness, and carburized surface hardness

none

Custom 465®

High-strength stainless steel with corrosion resistance, high strength and superior fracture toughness to withstand high torque loads in harsh environments for extended periods of time

none

Fine-Grain 718

Nickel-base alloy offering exceptionally high yield strength and fatigue life with superior corrosion resistance

Additive Manufacturing

Partner with us for end-to-end production of components created with electron beam and laser powder bed fusion additive manufacturing in our production facilities with powder lifecycle management and risk mitigation.

FEATURED PRODUCTS

none

718

This nickel-base alloy offers exceptionally high yield, tensile and creep-rupture properties up to 1300°F (704°C) in a weldable material with corrosion resistance

none

CCM

Non-magnetic cobalt-chromium-molybdenum alloy exhibiting high strength, corrosion resistance, and wear resistance

none

Custom 630 (17Cr-4Ni)

Martensitic precipitation, age-hardenable stainless alloy offering high strength and hardness, excellent corrosion resistance

none

316L

Austenitic stainless steel with corrosion resistance, as well as higher tensile and creep strength

none

Ti 6Al-4V

A fully heat treatable workhorse alloy performs well at temperatures up to 650F/350C offering strength with light weight and corrosion resistance

Innovative materials engineered for energy applications.

For our customers in the Energy Exploration and Production (E&P) and Power Generation industries, we improve system integrity and durability, extending component operating life to lower the total cost of ownership. Our diverse materials portfolio of over 300 grades of specialty alloys, superalloys, stainless steels, titanium, and metal powders make it possible.

These expertly engineered and manufactured alloys offer superior reliability and performance, making them popular choices for use in steam, gas, and wind turbines as well as a variety of other precision components employed by the E&P industry, renewable, and nuclear power generation systems.

Related Resources

Browse our growing library of resources for the energy market including case studies, product brochures, technical data sheets, product selection guides and more.