energy

Offshore Oil & Gas

Operating in the Most Challenging Environments with Confidence

Our team of industry experts tackles the toughest offshore oilfield challenges, understanding the need for long service lives and zero failure tolerance in difficult-to-service environments. We consult with customers on our innovative, best performing materials that withstand the effects of extreme corrosion, pressure, stress, and temperature to offer subsea integrity and increased performance.

APPLICATION SPOTLIGHT

Offshore Oil & Gas

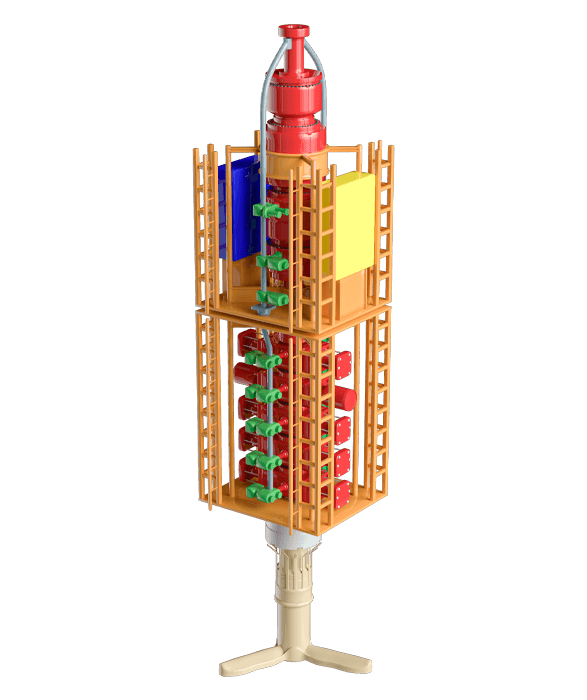

Subsea Drilling Equipment

Offshore drilling operations take place in a complex, challenging environment where failure is not an option. Every component from seafloor to surface must meet the highest standards for capability and quality. Our specialty alloys allow operators to drill with confidence and preserve their social license to operate.

FEATURED PRODUCTS

none

AerMet® 100

Precipitation hardenable, alloy steel with superior strength and fracture toughness. Utilized for critical components including shear ram blades for blowout preventers

none

MP35N®

Ultra-high tensile strength, good ductility, and toughness that is virtually immune to stress corrosion cracking and crevice corrosion in seawater

none

718 per API 6ACRA

Nickel-base alloy that offers high yield strength and corrosion resistance

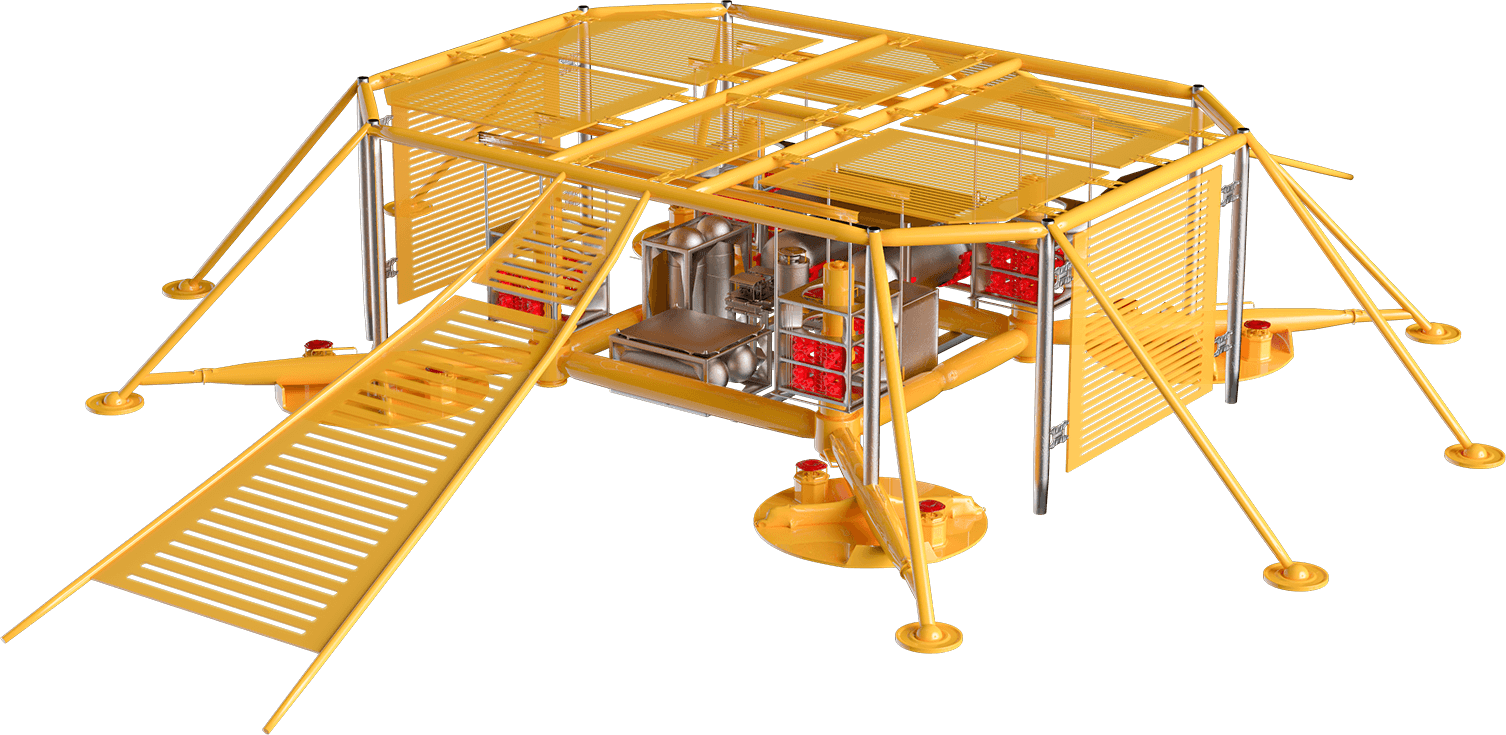

Artificial Lift

Electric submersible pumps (ESPs) are increasingly compact, with higher torque and more reliable performance. Higher power density enables rigless deployment systems to reduce workover costs in remote locations.

FEATURED PRODUCTS

none

Hiperco® 50

Soft magnetic alloy with high saturation and DC maximum permeability with low DC coercive force and AC core loss. Used with motor laminations to increase power density and reduce operating temperatures

none

718 Pump-Shaft Quality

Nickel-base alloy that offers high yield strength and corrosion resistance. Available in cold-worked-and-aged condition for superior strength

none

625

Solid-solution-strengthened nickel-base alloy with strength, toughness, and stress-corrosion cracking resistance in chloride solutions

none

625 Plus

Precipitation-hardenable, nickel-base alloy with superior corrosion resistance and improved pitting and hydrogen stress cracking resistance. Available in cold-worked and aged condition for superior strength

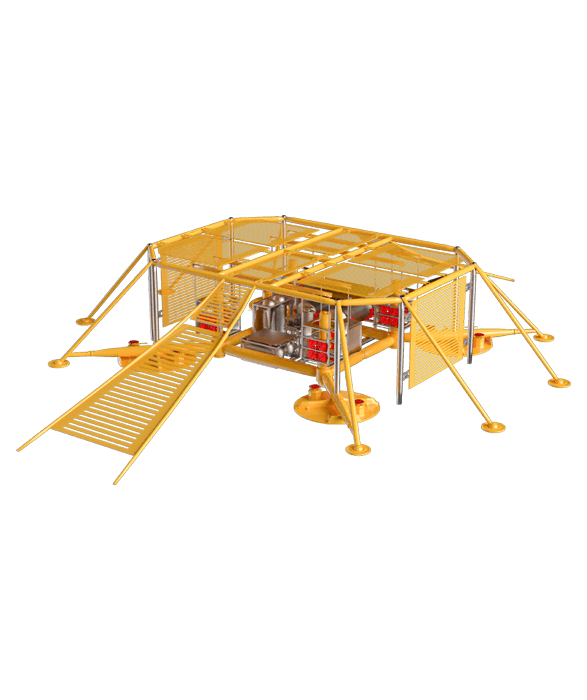

Subsea Production

High pressures and widely ranging temperatures create extreme environments. Hydrogen embrittlement leads to premature failure. We have designed materials to overcome these obstacles and maximize your production efficiency.

FEATURED PRODUCTS

none

718 per API 6ACRA

This nickel-base alloy offers high yield, strength, and corrosion resistance

none

725 per API 6ACRA

Precipitation hardenable, nickel-base alloy with exceptional resistance to stress corrosion cracking, pitting, and crevice corrosion in age hardened condition

none

625 Plus per API 6ACRA

Precipitation-hardenable, nickel-base alloy with superior corrosion resistance and improved pitting and hydrogen stress cracking resistance

none

MP35N®

Ultra-high tensile strength, good ductility, and toughness that is virtually immune to stress corrosion cracking and crevice corrosion in seawater

none

2205 & 2507

Duplex stainless steels with excellent strength and corrosion resistance. Qualified to NORSOK-M650

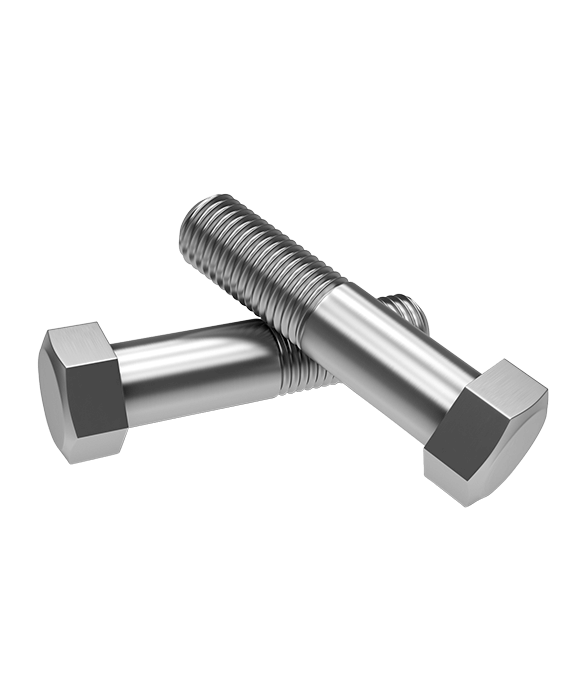

Fasteners

The importance of fasteners in subsea drilling and completions has been brought to the forefront by high-profile near-miss incidents. Offshore operations, particularly in deep water, necessitate that these critical structural components be specified and manufactured using industry-leading standards like API 20F. The potential costs of failure in terms of damage to health, safety, and the environment are enormous.

FEATURED PRODUCTS

none

MP35N®

Ultra-high tensile strength, good ductility, and toughness that is virtually immune to stress corrosion cracking and crevice corrosion in seawater

none

625 Plus per API 6ACRA

Precipitation hardenable, nickel-based alloy with exceptional resistance to stress corrosion cracking, pitting, and crevice corrosion in the age-hardened condition

none

718 per API 6ACRA

This nickel-base alloy offers exceptionally high yield, tensile and creep-rupture properties with high resistance to hydrogen embrittlement

none

A-286 (ASTM A453 Grade 660)

Iron-base austenitic stainless steel that is precipitation hardened and strengthened by heat treatment, providing improved corrosion resistance over alloy steel grades

Rotary Steerable Systems and Mud Motors

Demands for increased efficiency in directional drilling operations have placed extreme requirements on drilling tools. Higher torque loads, shock and vibration, and expectations of tool reliability require best-in-class materials to provide the foundation for industry-leading performance.

FEATURED PRODUCTS

none

PremoMax®

Premium alloy steel designed for mud motor transmission with a combination of high strength with impact and fracture toughness. Further surface hardening is possible for applications with high bearing loads through carburization or laser hardening treatments

none

A-21®

A next-generation martensitic stainless steel providing a step-change in performance for applications including power section rotors. Its unique microstructure and simple heat treatment provide superior properties and dimensional stability

none

Custom 465®

Premium, double-vacuum-melted stainless steel with superior strength and toughness. Robust field performance in leading drilling tools for applications including constant velocity joints and drive shafts

none

13CR-8NI

Double-vacuum-melted stainless steel with superior strength and toughness. Field-proven for applications including constant velocity joints and drive shafts in motors and drillstring agitation tools

none

15Cr-5Ni

Combination of high strength and toughness to withstand environments with high torque, shock loading, and fatigue

Drill Collars

Proprietary grades of non-magnetic stainless steels specifically for directional drilling operations in corrosive and highly stressed environments. Industry-leading alloy design and processing give unsurpassed resistance to pitting, stress corrosion cracking, and fatigue life, resulting in up to a tenfold improvement in tool life.

FEATURED PRODUCTS

none

15-15LC® Modified

Nitrogen-strengthened austenitic stainless steel with low carbon content to provide improved resistance to intergranular stress-corrosion cracking with 110 ksi (758 MPa) yield strength

none

15-15HS Max

Nitrogen-strengthened and warm-worked austenitic stainless steel with 140 ksi (966 MPa) minimum yield strength

none

SCF 260®

Nitrogen-strengthened austenitic stainless steel possessing 140 ksi (966 MPa) minimum yield strength and corrosion resistance in chloride environments. Field-proven performance in the North American unconventional drilling market

none

SCF 19® Max

Nitrogen-strengthened austenitic stainless steel with a combination of superior pitting and stress-corrosion-cracking resistance, high strength and fatigue life, and low magnetic permeability. Proven field performance in aggressive drilling brines and sour reservoirs

Work with Carpenter Technology to improve your product and your process.

Our materials help you lower the cost-per-foot drilled and total cost of ownership. Our superalloys, non-magnetic stainless steels, alloy steels, and custom stainless materials improve performance and increase component life in harsh environments.

Related Resources

Browse our growing library of resources for the market including case studies, product brochures, technical data sheets, product selection guides, and more.