energy

Onshore Oil & Gas

Quality Components Save Time and Money

Our customers can drill and produce confidently in extreme environments thanks to our extensive oil and gas experience. Carpenter Technology materials perform best, helping to avoid loss of valuable tools and production time. Our teams solve root causes of customers’ technical challenges.

APPLICATION SPOTLIGHT

Onshore Oil & Gas

Drill Collars

Proprietary grades of non-magnetic stainless steels specifically for directional drilling operations in corrosive and highly stressed environments. Industry-leading alloy design and processing give unsurpassed resistance to pitting, stress corrosion cracking, and fatigue life, resulting in up to a tenfold improvement in tool life.

FEATURED PRODUCTS

none

15-15LC® Modified

Nitrogen-strengthened austenitic stainless steel with low carbon content to provide improved resistance to intergranular stress-corrosion cracking with 110 ksi (758 MPa) yield strength

none

15-15HS Max

Nitrogen-strengthened austenitic stainless steel for high strength 140 ksi (966 MPa) minimum yield strength

none

SCF 260®

Nitrogen-strengthened austenitic stainless steel possessing 140 ksi (966 MPa) minimum yield strength and corrosion resistance in chloride environments. Field-proven performance in the North American unconventional drilling market

none

SCF 19® Max

Nitrogen-strengthened austenitic stainless steel with a combination of superior pitting and stress-corrosion-cracking resistance, high strength and fatigue life, and low magnetic permeability. Proven field performance in aggressive drilling brines and sour reservoirs

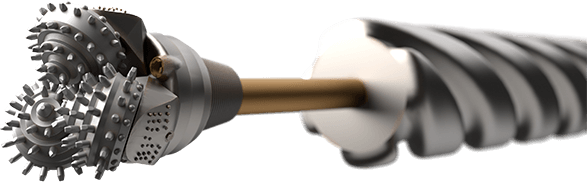

Mud Motors

Demands for increased efficiency in directional drilling operations have placed extreme requirements on drilling tools. Higher torque loads, shock and vibration, and expectations of tool reliability require best-in-class materials to provide the foundation for industry-leading performance.

FEATURED PRODUCTS

none

PremoMax®

Premium alloy steel designed for mud motor transmission with a combination of high strength with impact and fracture toughness. Further surface hardening is possible for applications with high bearing loads through carburization or laser hardening treatments

none

A-21®

A next-generation martensitic stainless steel providing a step-change in performance for applications including power section rotors. Its unique microstructure and simple heat treatment provide superior properties and dimensional stability

none

Custom 465®

Premium, double-vacuum-melted stainless steel with superior strength and toughness. Robust field performance in leading drilling tools for applications including constant velocity joints and drive shafts

none

13CR-8NI

Double-vacuum-melted stainless steel with superior strength and toughness. Field-proven for applications including constant velocity joints and drive shafts in motors and drillstring agitation tools

none

15Cr-5Ni

Combination of high strength and toughness to withstand environments with high torque, shock loading, and fatigue

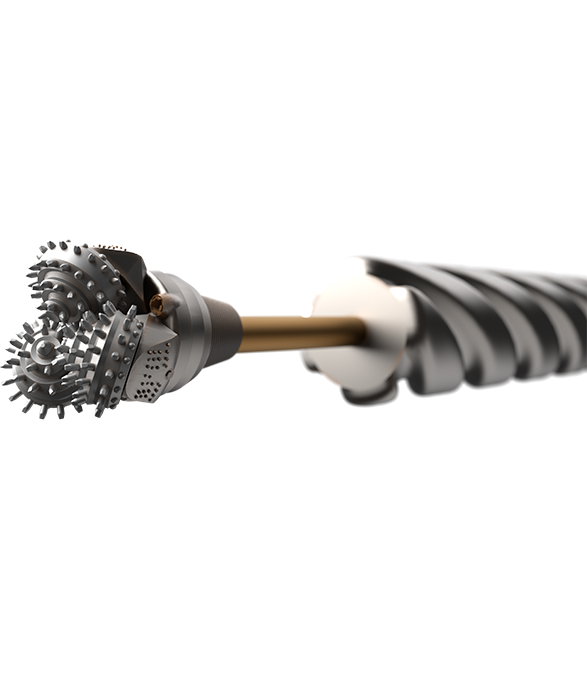

Rotary Steerable Systems

The increasing use of rotary steerable systems for onshore directional drilling requires more efficient assets than ever before. Our portfolio of premium alloys enables increased performance and reliability while extending asset lifetimes and reducing lifecycle costs.

FEATURED PRODUCTS

none

Custom 465®

Premium, double-vacuum-melted stainless steel with superior strength and toughness. Robust field performance in leading drilling tools for applications including constant velocity joints and drive shafts

none

13CR-8NI

Double-vacuum-melted stainless steel with superior strength and toughness. Field-proven for applications including constant velocity joints and drive shafts in motors and drillstring agitation tools

none

15Cr-5Ni

Combination of high strength and toughness to withstand environments with high torque, shock loading, and fatigue

none

718

A variety of finished products including per API 718, fine-grain, and direct-aged conditions. This alloy can be readily tailored to maximize toughness, strength, or fatigue life while maintaining excellent corrosion resistance

none

Additive Manufacturing

Additive manufacturing (AM) is rapidly being adopted into RSS, which often feature components with complex internal flow paths, such as manifolds. We have experience producing components made from superalloys including 718 and Cobal-Chrome-Molybdenum (CCM) for RSS applications

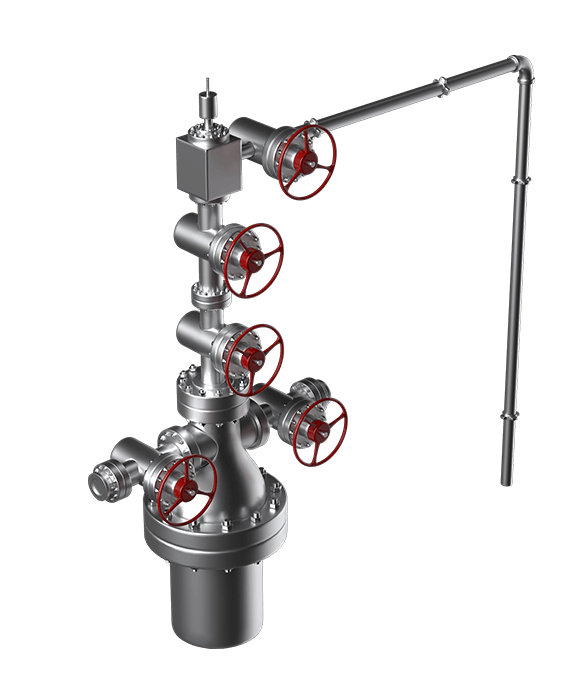

Wellheads

We supply industry-leading alloys to manufacturers specialized in the design and fabrication of pressure-containing and controlling surface equipment including wellheads, tubing hangers, valves, and blowout preventers. Strength, corrosion resistance, and reliability are key to ensuring safe, efficient operations.

FEATURED PRODUCTS

none

718 per API 6ACRA

Nickel-base alloy offering high yield strength and corrosion resistance

none

725 per API 6ACRA

Precipitation hardenable, nickel-base alloy with exceptional resistance to stress corrosion cracking, pitting, and crevice corrosion in age hardened condition

none

625 Plus per API 6ACRA

Precipitation-hardenable, nickel-base alloy with superior corrosion resistance, improved pitting, and hydrogen stress cracking resistance

none

MP35N®

Ultra-high tensile strength, good ductility, and toughness that is virtually immune to stress corrosion cracking and crevice corrosion

none

2205 and 2507

Duplex stainless steels with excellent strength and corrosion resistance qualified to NORSOK-M650

Artificial Lift

Electric submersible pumps (ESPs) are increasingly compact, with higher torque and more reliable performance. Higher power density enables rigless deployment systems to reduce workover costs in remote locations.

FEATURED PRODUCTS

none

Hiperco® 50

Soft magnetic alloy with high saturation and D.C. maximum permeability with low D.C. coercive force and A.C. core loss. Used in motor laminations to increase power density and reduce operating temperatures

none

718 Pump-Shaft Quality

Nickel-base alloy that offers high yield, strength, and corrosion resistance. Available in cold-worked-and-aged condition for superior strength

none

625

Solid-solution-strengthened nickel-base alloy with strength, toughness, and stress-corrosion cracking resistance in chloride solutions

none

625 Plus

Precipitation-hardenable, nickel-base alloy with superior corrosion resistance and improved pitting and hydrogen stress cracking resistance. Available in cold-worked and aged condition for superior strength

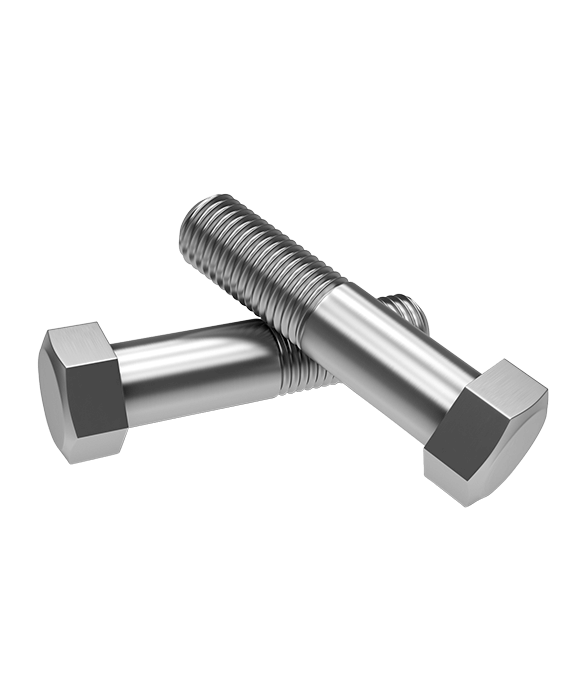

Fasteners

The importance of fasteners in drilling and completions has been brought to the forefront by high-profile near-miss incidents. Onshore operations, particularly those near population centers, necessitate that these critical structural components be specified and manufactured using industry-leading standards like API 20F. An uncontrolled release of hydrocarbons, particularly from a sour reservoir, can cause unacceptable damage to health, safety, and the environment, and threaten the industry’s social license to operate.

FEATURED PRODUCTS

none

MP35N®

Ultra-high tensile strength, good ductility, and toughness that is virtually immune to stress corrosion cracking and crevice corrosion in seawater

none

625 Plus per API 6ACRA

Precipitation hardenable, nickel-base alloy with exceptional resistance to stress corrosion cracking, pitting, and crevice corrosion in the age-hardened condition

none

718 per API 6ACRA

Nickel-base alloy that offers exceptionally high yield, tensile, and creep-rupture properties with high resistance to hydrogen embrittlement

none

A-286 (ASTM A453 Grade 660)

Iron-base austenitic stainless steel that is precipitation hardened and strengthened by heat treatment, providing improved corrosion resistance over alloy steel grades

Work with Carpenter Technology to improve your product and your process.

Our materials help you lower the cost-per-foot drilled and lower the total cost of ownership. Our non-magnetic stainless, alloy steels, and custom stainless materials, combined with our distribution, machining, and repair services help you drill in more aggressive environments with higher rates of penetration and increased component life.

Related Resources

Browse our growing library of resources for the market including case studies, product brochures, technical data sheets, product selection guides, and more.