We're your best partner for building a better future.

We collaborate to help you build a better future by bringing your best ideas forward.

We do that by developing better materials and smarter processes that transform what you are able to do and how you do it.

We grew to be one of the world’s leading specialty materials manufacturers by listening, learning, and solving extreme challenges. We help you think it through. And then we help you make it. For over 100 years we have applied our materials and manufacturing expertise to help people like you realize ideas and build success.

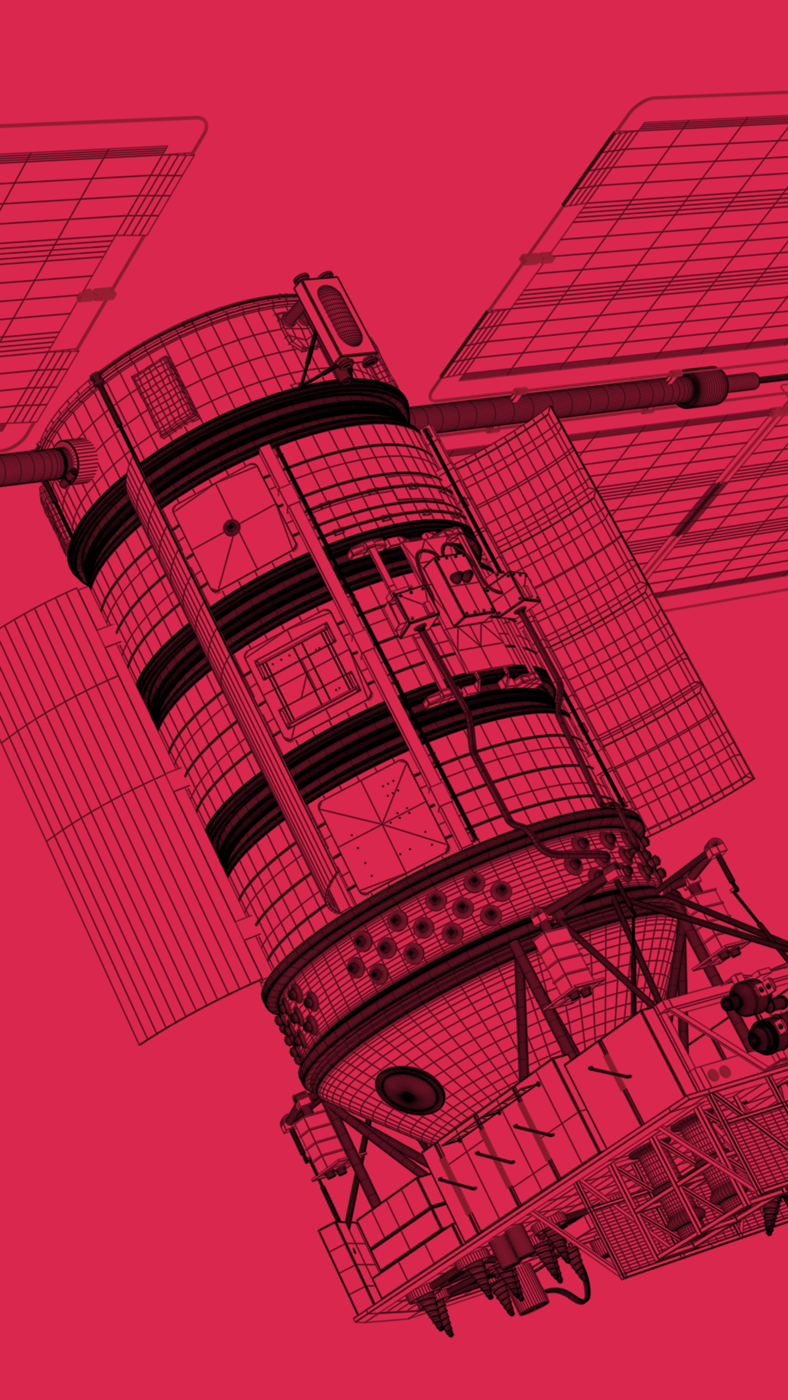

AEROSPACE

Superior materials for engines, landing gear, precision components, and metal powder additive manufacturing.

Transportation

Diverse specialty alloys for high-pressure fuel systems, engines, exhaust systems, oxygen sensors, and other components.

Consumer

Specialty alloys for durable and nondurable consumer goods applications from consumer electronics to sporting goods.

Defense

Advanced specialty materials for smaller, lighter, more durable components used in mission critical applications.

Energy

High-performance alloys and powders for power generation, renewables, and Oil and Gas drilling and completions applications.

Industrial

Corrosion, heat, and pressure resistant specialty alloys and stainless steels for valves, fittings, and fasteners.

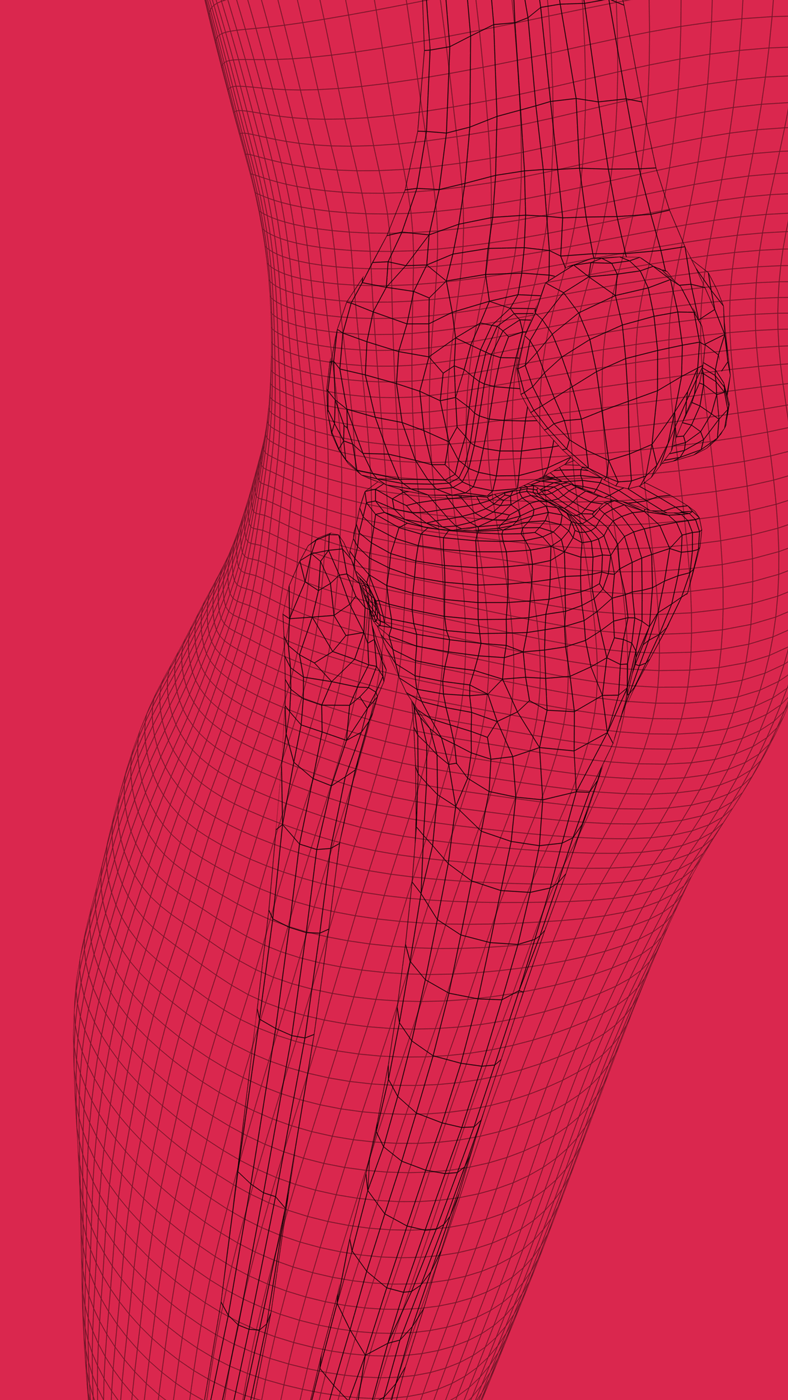

Medical

Titanium, stainless steel, and specialty alloys for surgical instruments, medical devices, prosthetics, and orthopedics.

MARKETS

Carpenter Technology is leading innovation and excellence by leveraging our technical strengths, distinct products, and extraordinary process capabilities to provide you with value-added solutions that create breakthrough results.

We help customers like you solve the most extreme materials challenges. Our high-performance solutions are the critical component for tomorrow's successes, helping you achieve superior results in all your current and anticipated problems.

PRODUCTS

Learn more about our specialty alloys and processed parts formulated for superior performance in mission critical applications.

Learn MoreINNOVATION

Step inside the world of Carpenter Technology’s research and development to learn about our material innovations and the breakthroughs in additive manufacturing and electrification technologies from our team of nearly 200 metallurgists and application engineers.

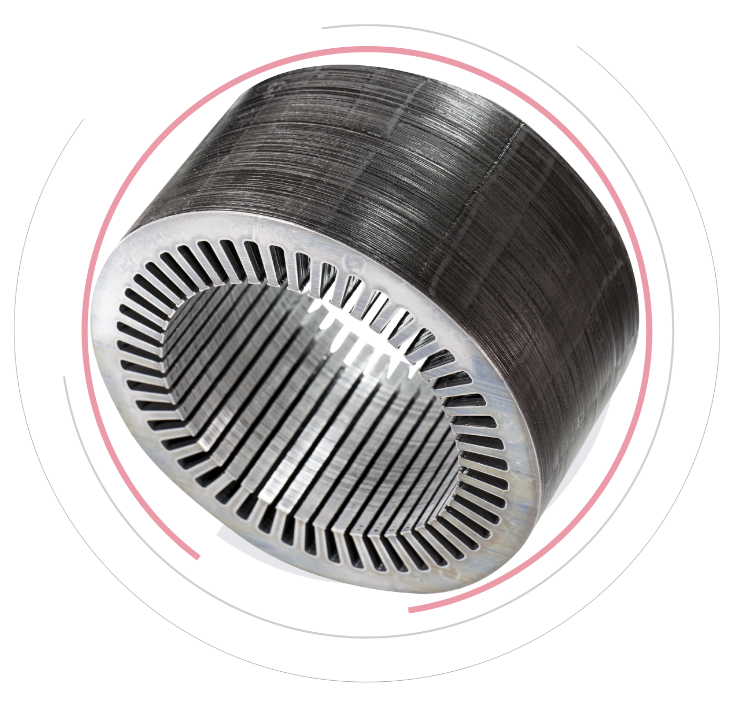

We continue to push the latest advancements in materials science. Partnering with our customers, we apply a rich 100-year history of expertise to meeting and exceeding their needs. We focus on redefining the limits of what is possible with ongoing alloy research and developments advancing emerging technologies such as additive manufacturing and magnetic stack lamination for electrification.

CASE

1

5

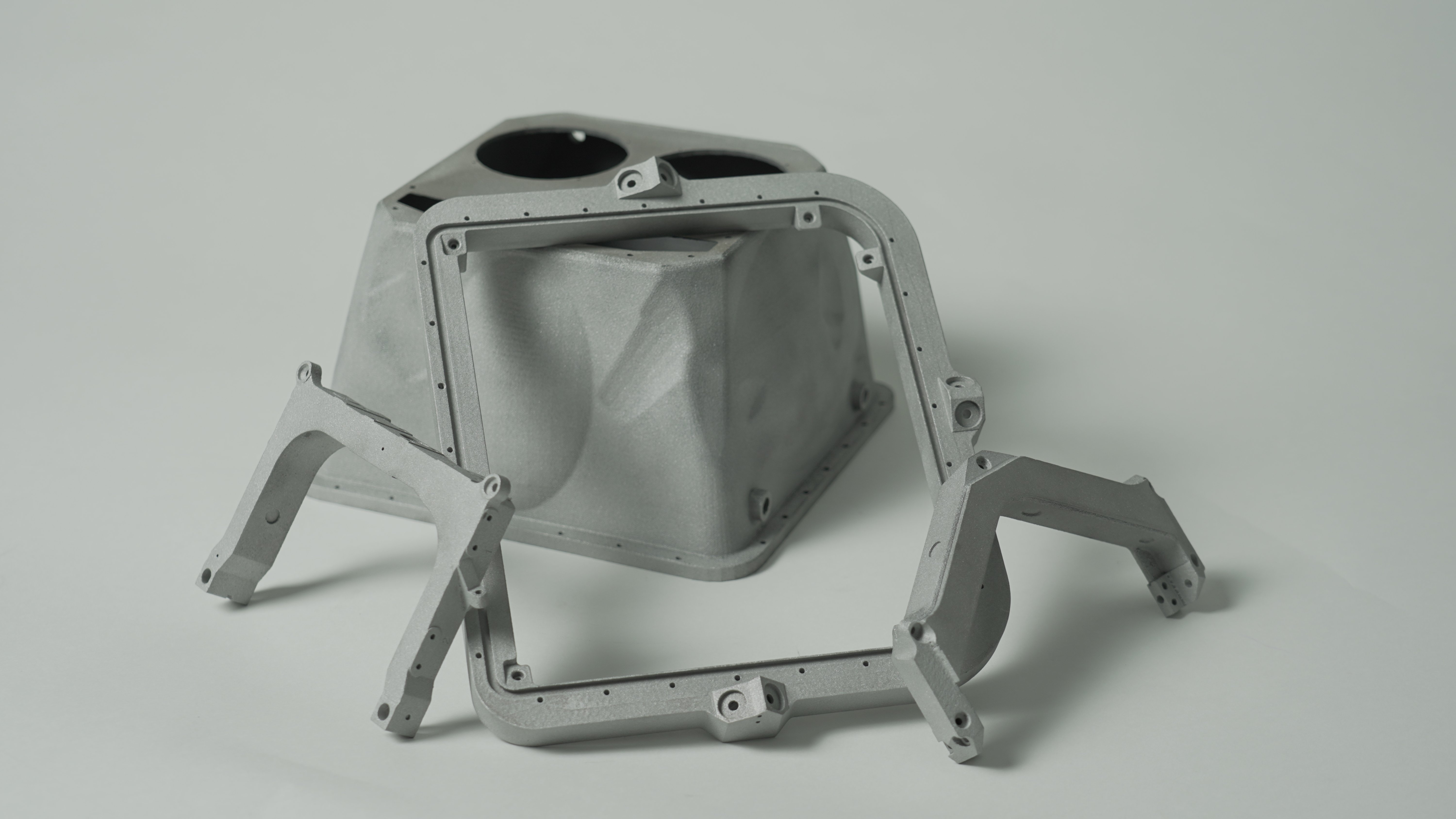

End-to-End Additive Manufacturing for the Mars Rover

CASE STUDY

Our additive manufacturing experts partnered with the NASA Jet Propulsion Laboratory to iterate to success on thin-walled, tight tolerance components for the PIXL. From deriving scale factors to staying on mass budget, we share our lessons learned and best practices.

CASE

2

5

Plasma & Electrode Inert Gas Atomized Powder Comparison

White Paper

Our team of additive manufacturing experts produced this white paper with results supporting the key conclusion that these Ti64 powders for additive manufacturing are statistically equivalent along several quantitative measures, including oxygen level, contamination, density, flowability, and morphology.

CASE

3

5

Ordered Growth in

Hiperco® 50 Alloys

White Paper

The Carpenter Electrification team understands the need for tight tolerance laminations for challenging design criteria. Aware of a net dimensional change in Hiperco® 50 alloys after post-fabrication annealing, we evaluated the root cause and designed a special process to improve the dimensional change characteristics.

CASE

4

5

Additive Manufacturing Success with Nitinol

White Paper

Our branch of 3D printing experts, Carpenter Additive, reports on their study to create a systematic framework to optimize additive manufacturing for Nitinol, used in the medical market for its superior superelasticity and shape memory effect.

CASE

5

5

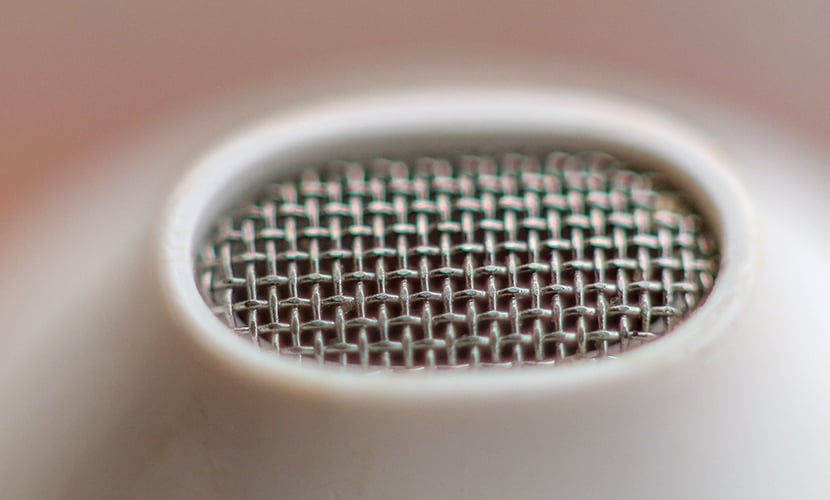

Optimizing Dynamic Drivers for Better Microspeaker Performance

White Paper

Magnetic circuits in consumer electronic devices are one of the key constraints in miniaturization. Carpenter Electrification took a holistic approach to model and improve the decibel density of microspeakers to increase sound pressure level while reducing operating current requirements.

from our blog

Exploring the Benefits of Nickel-Free and Cobalt-Free Alloys

"Discover the advantages of nickel-free and cobalt-free alloys in various industries, focusing on their high strength, corrosion resistance, and more."

READ MOREExploring Essential Titanium Shapes for Medical Materials

"Discover the essential titanium shapes and alloys for medical devices, enhancing safety, functionality, and patient outcomes with material solutions."

READ MORE VIEW ALL